|

ac5wzn00004587

AIM OF DEVELOPMENT

id000000011500

Vehicle Outline

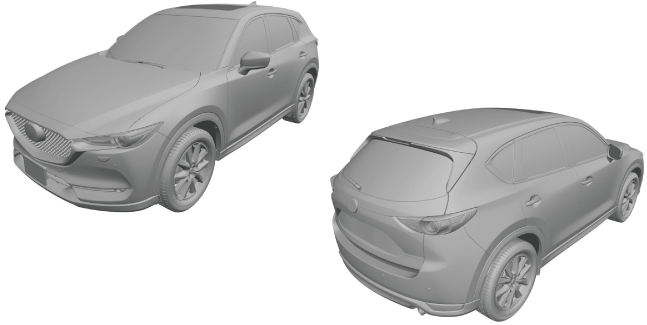

Exterior design

ac5wzn00004587

|

Interior design

ac5wzn00004588

|

Engine

ac5uun00003733

|

ac5wzn00005507

|

Suspension

ac5uun00002744

|

2WD

ac5uun00000310

|

4WD

ac5uun00000311

|

Driveline/Axle

Brakes

Vehicle front side (L.H.D.)

ac5wzn00005281

|

Vehicle front side (R.H.D.)

ac5wzn00005282

|

Vehicle rear side

ac5uun00002720

|

Vehicle front side (L.H.D.)

ac5wzn00005437

|

Vehicle front side (R.H.D.)

ac5wzn00005438

|

Vehicle rear side

ac5wzn00004818

|

Transmission/Transaxle

am3uun00001754

|

am6zzn00002618

|

am3uun00002419

|

ac5jjn00001299

|

Steering

L.H.D.

ac5wzn00005290

|

R.H.D.

ac5wzn00005291

|

Safety

Driver's support