DTC P055F:00

Engine oil pressure control circuit low oil pressure

DETECTION CONDITION

TYPE A (PCM part number: SHDN-188K2-A—B, SHDX-188K2-A—B, SHEA-188K2-A—B, SHEB-188K2-A, SHEE-188K2-A, SHEF-188K2-A, SHDG-188K2-A—B, SHDH-188K2-A, SHDJ-188K2-A—B, SHDK-188K2-A, SHDL-188K2-A—B, SHDM-188K2-A—B)

• The engine oil pressure is the specified value or less after the specified time has elapsed since the engine was started.

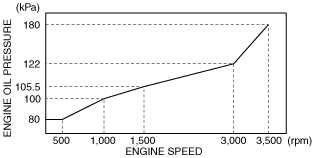

-

― Engine speed is 2,000 rpm or less: 80 kPa {0.82 kgf/cm2, 12 psi}― Engine speed is 2,000 to 3,500 rpm: 120 kPa {1.22 kgf/cm2, 17.4 psi}― Engine speed is 3,500 rpm or more: 180 kPa {1.84 kgf/cm2, 26.1 psi}

TYPE B (PCM part number: except SHDN-188K2-A—B, SHDX-188K2-A—B, SHEA-188K2-A—B, SHEB-188K2-A, SHEE-188K2-A, SHEF-188K2-A, SHDG-188K2-A—B, SHDH-188K2-A, SHDJ-188K2-A—B, SHDK-188K2-A, SHDL-188K2-A—B, SHDM-188K2-A—B)

• The engine oil pressure is the specified value or less after the specified time has elapsed since the engine was started.

-

― Engine speed is 2,000 rpm or less: 105 kPa {1.07 kgf/cm2, 15.2 psi}― Engine speed is 2,000 to 3,500 rpm: 120 kPa {1.22 kgf/cm2, 17.4 psi}― Engine speed is 3,500 rpm or more: 180 kPa {1.84 kgf/cm2, 26.1 psi}

Diagnostic support note

• This is a continuous monitor (CCM).

• The check engine light illuminates if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA/Snapshot data is available.

• DTC is stored in the PCM memory.

FAIL-SAFE FUNCTION

• PCM restricts engine torque.

• The fast idle up correction for the idle speed control is inhibited.

POSSIBLE CAUSE

• Engine oil leakage

• Improper engine oil level

• Engine oil temperature sensor/engine oil pressure sensor connector or terminals malfunction

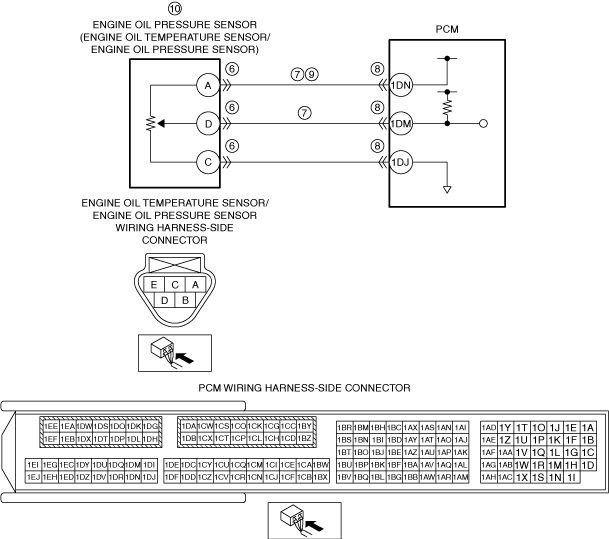

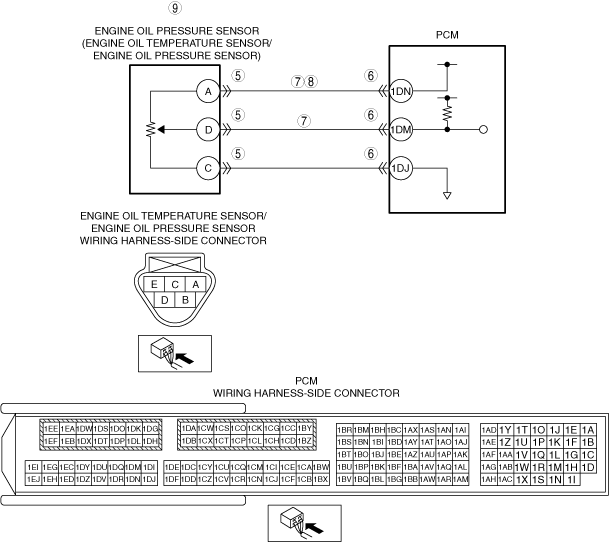

• Short to ground in wiring harness between the following terminals:

-

― Engine oil temperature sensor/engine oil pressure sensor terminal A—PCM terminal 1DN― Engine oil temperature sensor/engine oil pressure sensor terminal D—PCM terminal 1DM

• PCM connector or terminals malfunction

• Open circuit in wiring harness between engine oil temperature sensor/engine oil pressure sensor terminal A and PCM terminal 1DN

• Engine oil pressure sensor malfunction

• Oil strainer clogging

• Oil pump malfunction

• PCM malfunction