|

am6zzw00017889

DTC P2503:00 [PCM (SKYACTIV-D 2.2)]

id0102j5709600

Details On DTCs

|

System malfunction location |

Generator system: Voltage generated by generator is low |

|

|---|---|---|

|

Detection condition

|

Determination condition

|

• A condition continues for a specified period of time in which the generator target output current calculated by the PCM is 20 A or more and the generator output voltage is 8.5 V or less.

|

|

Preconditions

|

• Engine is running

|

|

|

determination period

|

• 5 s

|

|

|

Drive cycle

|

• 1

|

|

|

Self-test type

|

• CMDTC self test

|

|

|

Sensor/unit used

|

• PCM

• Generator

|

|

|

Fail-safe

|

• Inhibits the i-stop control.

|

|

|

Vehicle status when DTCs are output

|

• i-stop warning light (amber) flashes

• A warning message is displayed on the LCD in the instrument cluster.

|

|

|

Possible cause

|

• Poor connection of the following parts:

• Connector or terminal malfunction of the following parts:

• Malfunction in the following fuses:

• Short to ground in wiring harness between the following terminals:

• Open circuit in wiring harness between the following terminals:

• Generator drive belt shear, deviation, or wear

• Malfunction in generator

• PCM malfunction

|

|

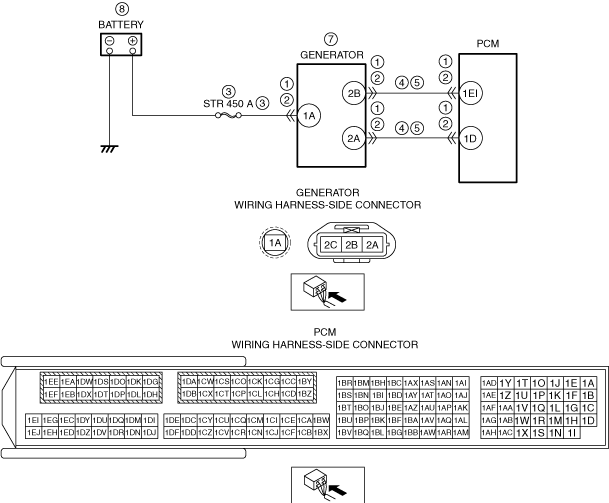

System Wiring Diagram

am6zzw00017889

|

Function Explanation (DTC Detection Outline)

Repeatability Verification Procedure

PID Item/Simulation Item Used in Diagnosis

Function Inspection Using M-MDS

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the freeze frame data/snap shot data.

|

—

|

Go to Troubleshooting Diagnostic Procedure to perform the procedure from step 1.

|

Troubleshooting Diagnostic Procedure

|

Step |

Inspection |

Results |

Action |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY IF POOR CONNECTION OF EACH PART AFFECTS DIAGNOSTIC RESULTS

• Switch the ignition OFF.

• Inspect the connection condition (part installation condition, connector connection condition) for the following parts:

• Is the connection condition (part installation condition, connector connection condition) for each part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Connect each part or the connector correctly, then go to the next step.

|

||

|

2

|

PURPOSE: VERIFY IF CONNECTOR DAMAGE OF EACH PART AFFECTS DIAGNOSTIC RESULTS

• Disconnect the connectors of the following parts:

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to the next step.

|

||

|

3

|

PURPOSE: INSPECT FOR MALFUNCTION DUE TO BAD FUSE

• Remove the STR 450 A fuse.

• Inspect the STR 450 A fuse.

• Is the STR 450 A fuse normal?

|

Yes

|

Install all the removed fuses, then go to the next step.

|

|

No

|

If the fuse is blown:

• Refer to the wiring diagram and verify if there is a common connector between the battery positive terminal and generator terminal 1A.

If there is a common connector:

If there is no common connector:

If the fuse is damaged:

• Replace the damaged fuse.

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY IF SHORT TO GROUND IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Verify that the generator and the PCM connectors are disconnected.

• Disconnect the battery connector.

• Inspect for continuity between the following terminals (vehicle wiring harness side) and ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Generator terminal 2B and PCM terminal 1BR

• Generator terminal 2A and PCM terminal 1Z

If there is a common connector:

If there is no common connector:

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: VERIFY IF OPEN CIRCUIT IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Verify that the battery and generator connectors, and the PCM connector are disconnected.

• Verify that the IG1 relay is removed.

• Inspect between the following terminals (vehicle wiring harness side) for continuity.

• Is there continuity?

|

Yes

|

Go to Step 8.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Generator terminal 2B and PCM terminal 1EI

• Generator terminal 2A and PCM terminal 1D

If there is a common connector:

If there is no common connector:

Go to the next step.

|

||

|

6

|

PURPOSE: VERIFY IF DIAGNOSTIC RESULT IS AFFECTED BY MALFUNCTION RELATED TO GENERATOR DRIVE BELT

• Inspect the generator drive belt.

• Is the indicator mark on the drive belt auto tensioner within the normal range?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the generator drive belt, then go to the next step.

|

||

|

7

|

PURPOSE: DETERMINE INTEGRITY OF GENERATOR

• Inspect the generator.

• Is the generator normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the generator, then go to the next step.

|

||

|

8

|

PURPOSE: VERIFY BATTERY CHARGE CONDITION

• Inspect the battery.

(See BATTERY INSPECTION.)

|

—

|

Follow the inspection instructions, then go to the next step.

|

|

9

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Reconnect all disconnected connectors and hoses.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Implement the repeatability verification procedure.

• Display the DTCs using the M-MDS.

• Is DTC P2503:00 displayed?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

10

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|