TURBOCHARGER [SKYACTIV-D 2.2]

id0113z7706500

Purpose, Function

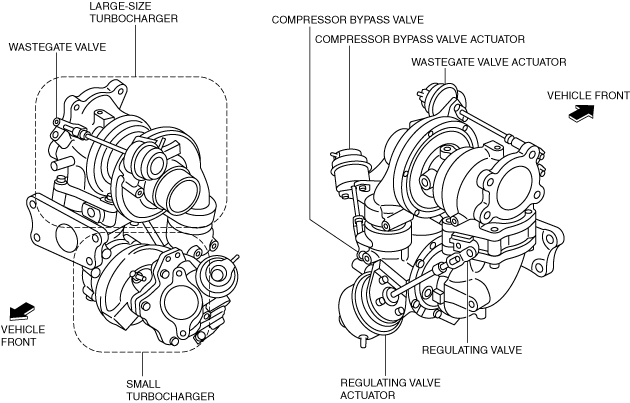

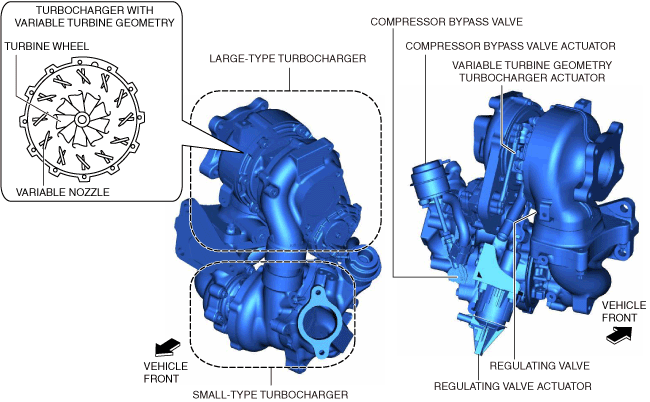

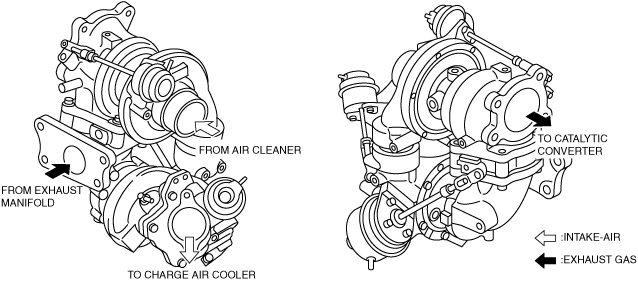

• The small-type turbocharger and large-type turbocharger are arranged in tandem enabling switching of the air charging between stage 1 and stage 2 by switching the intake/exhaust passages using each type of valve.

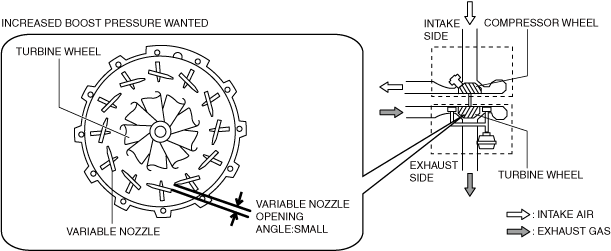

• A turbocharger with variable turbine geometry equipped with variable nozzles in the turbocharger has been adopted to improve the response in all speed ranges from low to high vehicle speeds. (Fuel injector (6pin type))

Construction

Fuel injector (2pin type)

-

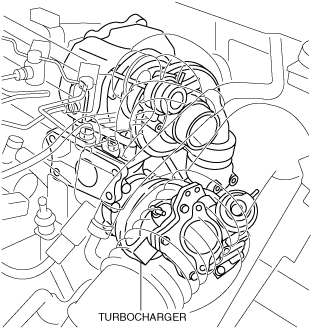

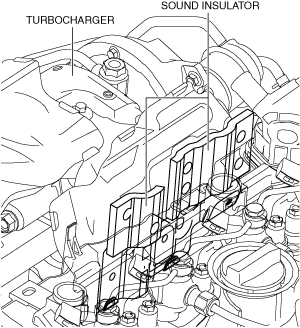

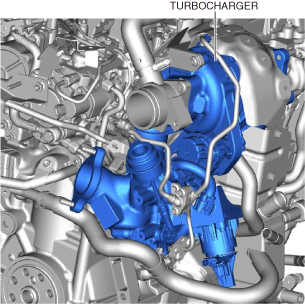

• The turbochargers are installed behind the engine compartment.

• The turbochargers consist of a large-type turbocharger, small-type turbocharger, each type of valve, and each type of actuator.

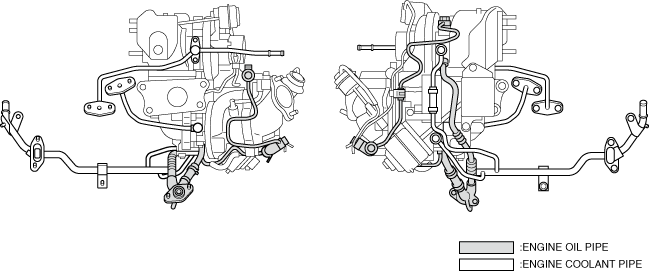

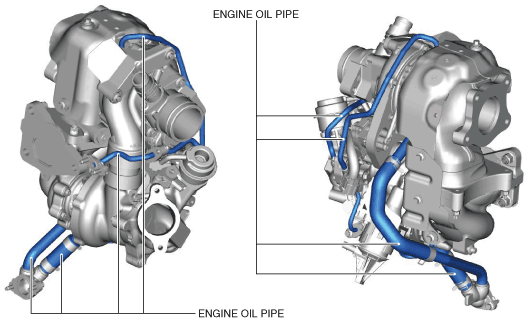

• To assure turbocharger functionality, a cooling pipe and engine oil pipe are installed.

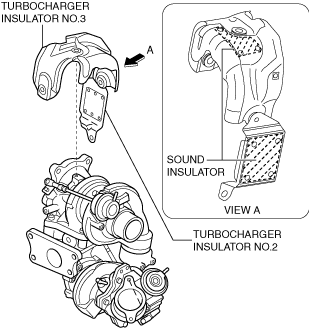

• Noise suppression material is employed on turbocharger insulator No.2 and No.3 to reduce engine noise transmitted to the vehicle cabin.

• Noise suppression material is employed between the turbochargers and the engine to reduce engine noise transmitted to the vehicle cabin.

Fuel injector (6pin type)

-

• The turbochargers are installed behind the engine compartment.

• The turbochargers consist of a large-type turbocharger, small-type turbocharger, each type of valve, and each type of actuator.

• To assure turbocharger reliability, the engine oil pipes are installed.

• Noise suppression material is employed between the turbocharger insulators No.2 and 3 to reduce engine noise transmitted to the vehicle cabin.

• Noise suppression material is employed between the turbochargers and the engine to reduce engine noise transmitted to the vehicle cabin.

Operation

Fuel injector (2pin type)

-

• When exhaust gas flows from the turbine impeller of the turbocharger, the compressor impeller on the same axle as the turbine impeller rotates to compress the intake air.

• By the opening/closing of the compressor bypass valve, regulating valve, wastegate valve according to the engine operation conditions, air charging by the large-type turbocharger and small-type turbocharger is controlled in two stages.

-

Compressor bypass valve

-

• Normally, the spring force presses against the rod, keeping the compressor bypass valve closed. When the vacuum generated by the vacuum pump operation is applied to the diaphragm chamber of the compressor bypass valve actuator, the rod is pulled to open the compressor bypass valve.

-

Regulating valve

-

• Normally, the spring force presses against the rod, keeping the regulating valve open. When the vacuum generated by the vacuum pump operation is applied to the diaphragm chamber of the regulating valve actuator, the rod is pulled to close the regulating valve.

-

Wastegate valve

-

• Normally, the spring force presses against the rod, keeping the wastegate valve open. When the vacuum generated by the vacuum pump operation is applied to the diaphragm chamber of the wastegate valve actuator, the rod is pulled to close the wastegate valve.

Fuel injector (6pin type)

-

• When exhaust gas flows to the turbine wheel of the turbocharger, the compressor wheel on the same axle as the turbine wheel rotates to compress the intake air.

• By the opening/closing of the compressor bypass valve, regulating valve, valve of the turbocharger with variable turbine geometry according to the engine operation conditions, boost by the large-type turbocharger and small-type turbocharger is controlled in two stages.

-

Compressor bypass valve

-

• Normally, the spring force presses against the rod, keeping the compressor bypass valve closed. When the vacuum generated by the vacuum pump operation is applied to the diaphragm chamber of the compressor bypass valve actuator, the rod is pulled to open the compressor bypass valve.

-

Regulating valve

-

• The regulating valve is controlled according to the duty signal from the PCM.

-

Variable nozzle

-

• The variable nozzle is controlled according to the signal from the PCM.

Increasing boost pressure

-

― By decreasing the opening angle of the variable nozzle, the exhaust gas flow speed increases and the turbine wheel rotation speed increases. Generally, when the engine speed increases and the exhaust gas increases, the opening angle of the variable nozzles gradually increases to flow the exhaust smoothly.

Decreasing boost pressure

-

― By increasing the opening angle of the variable nozzle, the exhaust gas flow speed decreases, the turbine wheel rotation speed decreases, and boost pressure decreases. The opening angle of the variable nozzle may become smaller depending on the opening angle conditions of each EGR system valve and the engine speed.

Excess speed prevention control

-

― To prevent the turbocharger with variable turbine geometry from operating in excess speed, the opening angle of the variable nozzles and fuel injection amount are controlled so that the turbo rotation speed is the specified value or less.