EGR CONTROL [SKYACTIV-G 2.5T]

id0140h0161400

Outline

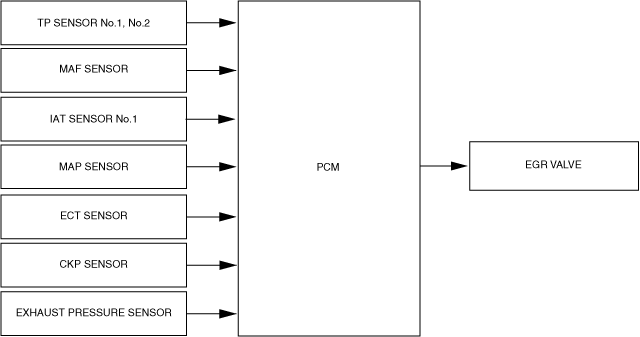

• To recirculate an optimum amount of exhaust gas to the combustion chamber according to engine operation conditions, the PCM controls the EGR valve (stepping motor) to open and close the valve.

• The intake gas temperature increases or decreases rapidly according to the exhaust gas temperature, and it affects the combustion temperature. To optimize the temperature of the recirculated exhaust gas, the opening and closing of the EGR valve are controlled according to the engine coolant temperature.

Block Diagram

Operation

Stepping motor drive principles

-

• The PCM opens/closes the EGR valve by controlling the amount of stepping motor rotation (maximum step number: 68).

• If the current EGR valve opening angle is smaller than the target EGR valve opening angle, the PCM increases the stepping motor step number and opens the EGR valve. If larger, the PCM decreases the stepping motor step number and closes the EGR valve. In addition, the stepping motor step number increases and decreases 1 step at a time.

• The energization condition of stepping motor coils No.1 to 4 can be verified by verifying the step number using “SEGRP” on the PID/data monitor function of the Mazda Modular Diagnostic System (M-MDS).

Step number calculation method

-

• The PCM determines the number of steps to drive the EGR valve using the following methods.

1. The PCM determines the target EGR rate so that the EGR volume is optimized according to the engine operation conditions. The target EGR rate is calculated based on the basic EGR rate.

-

Basic EGR rate

-

• The EGR rate is calculated according to the engine speed and the charging efficiency*1.

*1 :Charging efficiency is the ratio of the actual amount of intake air to the maximum air charging amount (mass volume) of the cylinder. This value increases proportionately to the increase in engine load.

2. The PCM determines the target EGR flow amount so that the target EGR rate is achieved.

-

Target EGR flow amount

-

• Calculated based on the information such as the engine speed and intake airflow amount (D-jetronic/L-jetronic).

-

• The PCM calculates the target EGR valve opening angle to achieve the target EGR flow amount. The PCM converts the target EGR valve opening angle to the step number and controls the EGR valve.

Target EGR valve opening angle

-

― Calculated based on the information such as the exhaust gas pressure sensor and the MAP sensor.

• The PCM controls the EGR valve depending on the step number converted from the target EGR valve opening angle.

Inhibition conditions

-

• To improve driveability and ensure exhaust emission performance, the EGR valve fully closes when any of the following conditions is met.

-

― Ignition is switched to OFF or ignition is switched to ACC or ON (engine off)

― Engine coolant temperature sensor: 70 °C {158 °F} or less

― During deceleration

― Engine speed: 1,200 rpm or less

― Charging efficiency: 45 % or less

― IAT sensor: -3 °C {27 °F} or less

― During TCS control operation