Description

Blind spot monitoring (BSM) indicator light (RH) circuit malfunction

Detection condition

• Blind spot monitoring (BSM) control module (RH) performs measurement at 0.01 s intervals and a short to ground in the blind spot monitoring (BSM) indicator light (RH) circuit is detected 48 times continuously.

Fail-safe

• Blind spot monitoring (BSM) system is stopped.

Possible cause

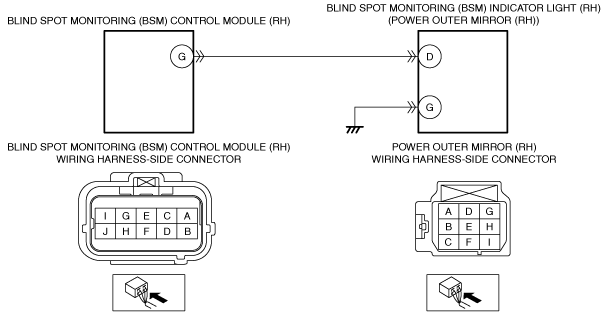

• Power outer mirror (RH) connector or terminal malfunction

• Blind spot monitoring (BSM) control module (RH) connector or terminal malfunction

• Short to ground in wiring harness between blind spot monitoring (BSM) control module (RH) terminal G and power outer mirror (RH) terminal D

• Blind spot monitoring (BSM) indicator light (RH) malfunction

• Blind spot monitoring (BSM) control module (RH) malfunction