|

TURBOCHARGER INSPECTION [SKYACTIV-D 2.2]

id0113z7801000

Prior Inspection

1. Inspect the idle speed. (See ENGINE TUNE-UP [SKYACTIV-D 2.2].)

2. Verify if a Soot Accumulation in diesel particulate filter too high or diesel particulate filter Inspection Required message is displayed in multi-information display.

3. Verify if the fuel tank level warning light is illuminated.

4. Inspect the oil level. (See ENGINE OIL LEVEL INSPECTION [SKYACTIV-D 2.2].)

5. Inspect the fuel filter. (See FUEL FILTER INSPECTION [SKYACTIV-D 2.2].)

6. Inspect the vacuum pump and vacuum lines. (See VACUUM PUMP INSPECTION.) (See VACUUM LINE INSPECTION [SKYACTIV-D 2.2].)

7. Inspect the charge air cooler. (See CHARGE AIR COOLER INSPECTION [SKYACTIV-D 2.2].)

8. Inspect the intake-air system related hoses for disconnection.

9. Inspect the air cleaner element. (See AIR CLEANER ELEMENT INSPECTION [SKYACTIV-D 2.2].)

Symptom Troubleshooting Selection

|

MALFUNCTION |

DIAGNOSTIC SYSTEM INSPECTION ITEMS |

|---|---|

|

• Turbocharger malfunction

• Compressor bypass valve malfunction

• Regulating valve malfunction

• Turbocharger with variable turbine geometry malfunction

|

|

|

• Turbocharger shaft seal malfunction

|

|

|

• Interference with turbocharger rotation mechanism housing

|

(See Abnormal Noise Inspection.)

|

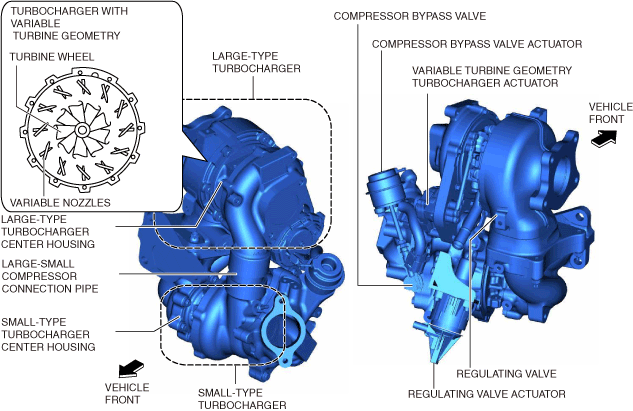

Structural view

ac8wzw00002651

|

Charging Deficiency Inspection

Large-type turbocharger charging deficiency inspection

Possible cause

|

MALFUNCTION OCCURRENCE LOCATION |

PHENOMENON |

CAUSE |

INSPECTION ORDER |

|

|---|---|---|---|---|

|

Large-type compressor side

|

Large-small compressor connection pipe

|

Pressurization leak

|

Connection looseness or disconnection of large-small compressor connection pipe

|

1

|

|

Compressor bypass valve

|

Pressurization leak

|

Crack in compressor bypass valve outlet

|

2

|

|

|

Small valve opening angle

|

Valve sticking

Rod link deformity

Vacuum malfunction in compressor bypass solenoid valve

|

6

|

||

|

Large-type turbine side

|

Between turbine inlet and exhaust manifold

Regulating valve

Between turbine outlet and catalytic converter

|

Exhaust gas leakage

|

Cracks

Gasket deterioration

|

3, 11

|

|

Regulating valve

|

Variable nozzle opening angle

|

Valve sticking

Rod link deformity, deviation, interference

Regulating valve actuator operation malfunction

|

4, 13

|

|

|

Exhaust gas leakage

|

Cracks

|

12

|

||

|

Turbocharger with variable turbine geometry

|

Variable nozzle opening angle

|

Turbocharger with variable turbine geometry cartridge sliding part sticking

Rod link deformity, deviation, interference

Variable turbine geometry turbocharger actuator operation malfunction

|

5

|

|

|

Exhaust gas leakage

|

Turbocharger with variable turbine geometry cartridge deformity, deviation

Foreign matter adhering to seal surface

|

10

|

||

|

Large-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

7

|

|

|

Large-type turbocharger shaft or bearing

|

Sticking or dislodged, broken large-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

8

|

|

|

Large-type turbine wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

9

|

|

Large-type turbocharger charging deficiency inspection (on-vehicle inspection)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

INSPECTION OF PRESSURIZATION LEAKAGE FROM LARGE-SMALL COMPRESSOR CONNECTION PIPE

• Inspect for disconnection, looseness in large-small compressor connection pipe.

• If there is even slight looseness, apply soapy water and verify if bubbles are produced while running the engine under no load (selector lever in P position, engine speed 3,700 rpm or more.)

• Are bubbles produced?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

2

|

INSPECTION OF PRESSURIZATION LEAKAGE FROM COMPRESSOR BYPASS VALVE OUTLET

• Inspect the compressor bypass valve outlet area for cracks.

• If cracking locations cannot be discerned, apply soapy water and verify if bubbles are produced while running the engine under no load (selector lever in P position, engine speed 3,700 rpm or more.)

• Are there cracks or bubbles produced?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECTION OF EXHAUST GAS LEAKAGE FROM LARGE-TYPE TURBINE SIDE

• Inspect the following locations for the sound of exhaust gas leakage.

• Is there exhaust gas leakage?

|

Yes

|

Go to Step 11 of the large-type turbocharger charging deficiency inspection (single-unit inspection).

|

|

No

|

Go to the next step.

|

||

|

4

|

REGULATING VALVE OPENING ANGLE INSPECTION

• Perform the following inspections.

|

Yes

|

Replace the turbocharger.

|

|

No

|

Inspect the vacuum pipe.

If it is normal, go to the next step.

If there is any malfunction, repair or replace the malfunctioning part.

|

||

|

5

|

TURBOCHARGER WITH VARIABLE TURBINE GEOMETRY OPENING ANGLE INSPECTION

• Perform the following inspections.

• Is there any malfunction in the inspection results?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

6

|

COMPRESSOR BYPASS VALVE OPENING ANGLE INSPECTION

• Perform the following inspections:

• Is there any malfunction in the inspection results?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

7

|

LARGE-TYPE COMPRESSOR WHEEL INSPECTION

• Remove the intake air hose and, using a mirror, visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

8

|

LARGE-TYPE TURBOCHARGER SHAFT AND BEARING INSPECTION

• Rotate the induction side by hand and inspect for play in the axial direction.

• Does the shaft not rotate smoothly or is there play of 0.5 mm {0.02 in} or more?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

9

|

LARGE-TYPE TURBINE WHEEL INSPECTION

• Remove the catalytic converter and visually inspect the wheel condition from the exhaust gas side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

10

|

Inspect the turbocharger with variable turbine geometry for gas leakage.

|

Yes

|

Replace the turbocharger.

|

|

No

|

Remove the turbocharger.

Go to Step 13 of the large-type turbocharger charging deficiency inspection (single-unit inspection).

|

Large-type turbocharger charging deficiency inspection (single-unit inspection)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

11

|

INSPECTION OF EXHAUST GAS LEAKAGE FROM TURBOCHARGER INSTALLATION AREA

• Visually inspect the following parts:

• Is there evidence of exhaust gas leakage on the gasket*, or cracks spreading to the edge of the gasket?

|

Yes

|

If there is evidence of exhaust gas leakage on the gasket, replace with an appropriate gasket.

If there are cracks on the edge of the gasket, replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

12

|

INSPECT FOR EXHAUST GAS LEAKAGE FROM THE TURBINE HOUSING OR REGULATING VALVE

• Are there cracks penetrating the turbine housing and regulating valve housing?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

13

|

INSPECTION OF REGULATING VALVE OPENING ANGLE

• Visually inspect the link area of the regulating valve.

• Is there deviation or interference?

|

Yes

|

Replace the turbocharger.

|

|

No

|

The large-type turbocharger is normal.

|

Small-type turbocharger charging deficiency inspection

Possible cause

|

MALFUNCTION OCCURRENCE LOCATION |

PHENOMENON |

CAUSE |

INSPECTION ORDER |

|

|---|---|---|---|---|

|

Small-type compressor side

|

Large-small compressor connection pipe

|

Pressurization leak

|

Connection looseness or disconnection of large-small compressor connection pipe

|

1

|

|

Compressor bypass valve

|

Pressurization leak

|

Crack in compressor bypass valve outlet

|

2

|

|

|

Large valve opening angle

|

Valve sticking

Rod link deformity

Vacuum malfunction in compressor bypass solenoid valve

|

5

|

||

|

Exhaust gas leakage

|

Valve deformity

Foreign matter adhering to seal surface

|

6

|

||

|

Small-type turbine side

|

Between turbine inlet and exhaust manifold

Between turbine outlet and catalytic converter

|

Exhaust gas leakage

|

Cracks

Gasket deterioration

|

3, 10

|

|

Regulating valve

|

Large valve opening angle

|

Valve sticking

Rod link deformity

Regulating valve actuator operation malfunction

|

4, 11

|

|

|

Exhaust gas leakage

|

Cracks

Valve deformity

Foreign matter adhering to seal surface

|

9, 10

|

||

|

Small-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

7

|

|

|

Small-type turbocharger shaft or bearing

|

Sticking or dislodged, broken small-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

8

|

|

Small-type turbocharger charging deficiency inspection (on-vehicle inspection)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

INSPECTION OF PRESSURIZATION LEAKAGE FROM LARGE-SMALL COMPRESSOR CONNECTION PIPE

• Inspect for disconnection, looseness in large-small compressor connection pipe.

• If there is even slight looseness, apply soapy water and verify if bubbles are produced while running the engine under no load (selector lever in P position, engine speed 1500 rpm.)

• Are bubbles produced?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

2

|

INSPECTION OF PRESSURIZATION LEAKAGE FROM COMPRESSOR BYPASS VALVE OUTLET

• Inspect the compressor bypass valve outlet area for cracks.

• If cracking locations cannot be discerned, apply soapy water and verify if bubbles are produced while running the engine under no load (selector lever in P position, engine speed 1500 rpm.)

• Are there cracks or bubbles produced?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECTION OF EXHAUST GAS LEAKAGE FROM SMALL-TYPE TURBINE SIDE

• Inspect the following locations for the sound of exhaust gas leakage.

• Is there exhaust gas leakage?

|

Yes

|

Go to Step 10 of the Small-type turbocharger charging deficiency inspection (single-unit inspection).

|

|

No

|

Go to the next step.

|

||

|

4

|

REGULATING VALVE ACTUATOR OPENING ANGLE INSPECTION

• Is there a malfunction in the regulating valve actuator? (See REGULATING VALVE ACTUATOR INSPECTION [SKYACTIV-D 2.2].) (See REGULATING VALVE ACTUATOR POSITION SENSOR INSPECTION [SKYACTIV-D 2.2].)

|

Yes

|

Perform turbocharger initialization and repeat inspection.

Replace turbocharger if malfunction occurs even after performing initialization.

|

|

No

|

Inspect the vacuum pipe.

If it is normal, go to the next step.

If there is any malfunction, repair or replace the malfunctioning part.

|

||

|

5

|

COMPRESSOR BYPASS VALVE OPENING ANGLE INSPECTION

• Perform the following inspections:

• Is there any malfunction in the inspection results?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

6

|

INSPECT FOR GAS LEAKAGE FROM COMPRESSOR BYPASS VALVE

• Remove the intake air hose and visually inspect the compressor bypass valve. (If there is foreign matter adhering such as carbon to the seal surface, remove it.)

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

7

|

INSPECTION OF SMALL-TYPE COMPRESSOR WHEEL

• Open the compressor bypass valve and visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Remove the turbocharger.

|

Small-type turbocharger charging deficiency inspection (single-unit inspection)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

8

|

INSPECTION OF EXHAUST GAS LEAKAGE FROM TURBOCHARGER INSTALLATION AREA

• Visually inspect the following parts:

• Is there evidence of exhaust gas leakage on the gasket*, or cracks spreading to the edge of the gasket?

|

Yes

|

If there is evidence of exhaust gas leakage on the gasket, replace with an appropriate gasket.

If there are cracks on the edge of the gasket, replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

9

|

INSPECT FOR EXHAUST GAS LEAKAGE FROM THE TURBINE HOUSING OR REGULATING VALVE

• Are there cracks penetrating the turbine housing and regulating valve housing?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

10

|

INSPECTION OF SMALL-TYPE TURBOCHARGER SHAFT AND BEARING

• Open the compressor bypass valve and verify that the rotation is smooth using a long object (long rod) from the intake air side.

• Is the part normal?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

11

|

INSPECTION OF REGULATING VALVE OPENING ANGLE

• Visually inspect the link area of the regulating valve.

• Is there deviation or interference?

|

Yes

|

Replace the turbocharger.

|

|

No

|

The Small-type turbocharger is normal.

|

Oil leakage inspection of compressor side

Possible cause

|

MALFUNCTION OCCURRENCE LOCATION |

PHENOMENON |

CAUSE |

INSPECTION ORDER |

|

|---|---|---|---|---|

|

Regulating valve

|

Largel valve opening angle

|

Valve sticking

Rod link deformity

Regulating valve actuator operation malfunction

|

1

|

|

|

Compressor bypass valve

|

Large valve opening angle

|

Valve sticking

Rod link deformity

Vacuum malfunction in compressor bypass solenoid valve

|

2

|

|

|

Exhaust gas leakage

|

Valve deformity

Foreign matter adhering to seal surface

|

5

|

||

|

Large-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

3

|

|

|

Large-type turbocharger shaft or bearing

|

Sticking or dislodged, broken large-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

4

|

|

|

Small-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

6

|

|

|

Small-type turbocharger shaft or bearing

|

Sticking or dislodged, broken small-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

7

|

|

Oil leakage inspection of compressor side

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

REGULATING VALVE ACTUATOR OPENING ANGLE INSPECTION

• Is there a malfunction in the regulating valve actuator? (See REGULATING VALVE ACTUATOR POSITION SENSOR INSPECTION [SKYACTIV-D 2.2].)

|

Yes

|

Replace the turbocharger.

|

|

No

|

Inspect the vacuum pipe.

If it is normal, go to the next step.

If there is any malfunction, repair or replace the malfunctioning part.

|

||

|

2

|

COMPRESSOR BYPASS VALVE OPENING ANGLE INSPECTION

• Perform the following inspections:

• Is there any malfunction in the inspection results?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

3

|

LARGE-TYPE COMPRESSOR WHEEL INSPECTION

• Remove the intake air hose and, using a mirror, visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

4

|

LARGE-TYPE TURBOCHARGER SHAFT AND BEARING INSPECTION

• Rotate the induction side by hand and inspect for play in the axial direction.

• Does the shaft not rotate smoothly or is there play of 0.5 mm {0.02 in} or more?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

5

|

INSPECT FOR GAS LEAKAGE FROM COMPRESSOR BYPASS VALVE

• Remove the intake air hose and visually inspect the compressor bypass valve. (If there is foreign matter adhering such as carbon to the seal surface, remove it.)

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

6

|

INSPECTION OF SMALL-TYPE COMPRESSOR WHEEL

• Open the compressor bypass valve and visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

7

|

INSPECTION OF SMALL-TYPE TURBOCHARGER SHAFT AND BEARING

• Open the compressor bypass valve and verify that the rotation is smooth using a long object (long rod) from the intake air side.

• Is the part normal?

|

Yes

|

The turbocharger is normal.

|

|

No

|

Replace the turbocharger.

|

Oil leakage inspection on turbine side

Possible cause

|

MALFUNCTION OCCURRENCE LOCATION |

PHENOMENON |

CAUSE |

INSPECTION ORDER |

|

|---|---|---|---|---|

|

Large-type turbocharger center housing

|

Oil leakage

|

Cracks

Foreign matter adhering to seal surface

|

1

|

|

|

Small-type turbocharger center housing

|

Oil leakage

|

Cracks

Foreign matter adhering to seal surface

|

2

|

|

|

Large-type turbocharger shaft or bearing

|

Sticking or dislodged, broken large-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

3

|

|

|

Small-type turbocharger shaft or bearing

|

Sticking or dislodged, broken small-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

4

|

|

|

Large-type turbine wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

5

|

|

Oil leakage inspection on turbine side

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

INSPECT FOR OIL LEAKAGE FROM LARGE-TYPE TURBOCHARGER CENTER HOUSING

• Are there any cracks on the large-type turbocharger center housing?

• Is there any oil leakage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Inspect the vacuum pipe.

If it is normal, go to the next step.

If there is any malfunction, repair or replace the malfunctioning part.

|

||

|

2

|

INSPECT FOR OIL LEAKAGE FROM SMALL-TYPE TURBOCHARGER CENTER HOUSING

• Are there any cracks on the small-type turbocharger center housing?

• Is there any oil leakage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

3

|

LARGE-TYPE TURBOCHARGER SHAFT AND BEARING INSPECTION

• Rotate the induction side by hand and inspect for play in the axial direction.

• Does the shaft not rotate smoothly or is there play of 0.5 mm {0.02 in} or more?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

4

|

INSPECTION OF SMALL-TYPE TURBOCHARGER SHAFT AND BEARING

• Open the compressor bypass valve and verify that the rotation is smooth using a long object (long rod) from the intake air side.

• Is the part normal?

|

Yes

|

Go to Step 11 of the Small-type turbocharger charging deficiency inspection (single-unit inspection).

|

|

No

|

Replace the turbocharger.

|

||

|

5

|

LARGE-TYPE TURBINE WHEEL INSPECTION

• Remove the catalytic converter and visually inspect the wheel condition from the exhaust gas side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

The turbocharger is normal.

|

Abnormal Noise Inspection

Possible cause

|

MALFUNCTION OCCURRENCE LOCATION |

PHENOMENON |

CAUSE |

INSPECTION ORDER |

|

|---|---|---|---|---|

|

Large-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

1

|

|

|

Large-type turbocharger shaft or bearing

|

Sticking or dislodged, broken large-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

2

|

|

|

Small-type compressor wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

3

|

|

|

Small-type turbocharger shaft or bearing

|

Sticking or dislodged, broken small-type compressor installation nut

|

Foreign matter penetration

Deficient lubrication

|

4

|

|

|

Large-type turbine wheel

|

Wheel damage or sticking

|

Foreign matter penetration

Rotation exceeds threshold maximum

|

5

|

|

Abnormal noise inspection

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

LARGE-TYPE COMPRESSOR WHEEL INSPECTION

• Remove the intake air hose and, using a mirror, visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

2

|

LARGE-TYPE TURBOCHARGER SHAFT AND BEARING INSPECTION

• Rotate the induction side by hand and inspect for play in the axial direction.

• Does the shaft not rotate smoothly or is there play of 0.5 mm {0.02 in} or more?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

3

|

INSPECTION OF SMALL-TYPE COMPRESSOR WHEEL

• Open the compressor bypass valve and visually inspect the wheel condition from the intake air side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

Go to the next step.

|

||

|

4

|

INSPECTION OF SMALL-TYPE TURBOCHARGER SHAFT AND BEARING

• Open the compressor bypass valve and verify that the rotation is smooth using a long object (long rod) from the intake air side.

• Is the part normal?

|

Yes

|

Go to Step 11 of the Small-type turbocharger charging deficiency inspection (single-unit inspection).

|

|

No

|

Replace the turbocharger.

|

||

|

5

|

LARGE-TYPE TURBINE WHEEL INSPECTION

• Remove the catalytic converter and visually inspect the wheel condition from the exhaust gas side.

• Is there deformity or damage?

|

Yes

|

Replace the turbocharger.

|

|

No

|

The turbocharger is normal.

|