|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the freeze frame data/snap shot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY OTHER RELATED DTCs

• Switch the ignition OFF, and then switch it ON (engine off).

• Display the DTCs using the M-MDS.

• Has any DTC other than P0642:00 been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT APP SENSOR CONNECTOR CONDITION

• Switch the ignition OFF.

• Disconnect the APP sensor connector

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

4

|

INSPECT CKP SENSOR CONNECTOR CONDITION

• Disconnect the CKP sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

5

|

INSPECT MAP SENSOR NO.2 CONNECTOR CONDITION

• Disconnect the MAP sensor No.2 connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

6

|

INSPECT ENGINE OIL TEMPERATURE/ENGINE OIL PRESSURE SENSOR CONNECTOR CONDITION

• Disconnect the engine oil temperature/engine oil pressure sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

7

|

INSPECT MAF/IAT SENSOR NO.1 CONNECTOR CONDITION

• Disconnect the MAF/IAT sensor No.1 connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

8

|

INSPECT POWER BRAKE UNIT VACUUM SENSOR CONNECTOR

• Disconnect the power brake unit vacuum sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

9

|

INSPECT REFRIGERANT PRESSURE SENSOR CONNECTOR CONNECTION

• Disconnect the Refrigerant pressure sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

10

|

INSPECT FUEL PRESSURE SENSOR (INTEGRATED WITH FUEL INJECTOR NO.1) CONNECTOR CONDITION

• Disconnect the fuel pressure sensor (integrated with fuel injector No.1) connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

11

|

INSPECT FUEL PRESSURE SENSOR (INTEGRATED WITH FUEL INJECTOR NO.4) CONNECTOR CONDITION

• Disconnect the fuel pressure sensor (integrated with fuel injector No.4) connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

12

|

INSPECT VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR/VARIABLE TURBINE GEOMETRY TURBOCHARGER ACTUATOR POSITION SENSOR CONNECTOR CONDITION

• Disconnect the variable turbine geometry turbocharger actuator position sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

13

|

INSPECT EGR COOLER BYPASS VALVE/EGR COOLER BYPASS VALVE POSITION SENSOR CONNECTOR CONDITION

• Disconnect the EGR cooler bypass valve/EGR cooler bypass valve position sensor connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

14

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector, then go to Step 16.

|

|

15

|

INSPECT EACH POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

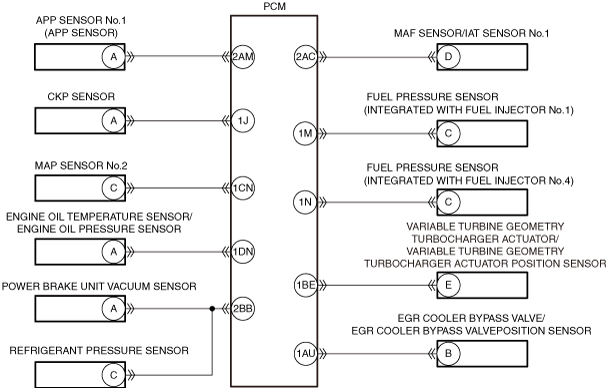

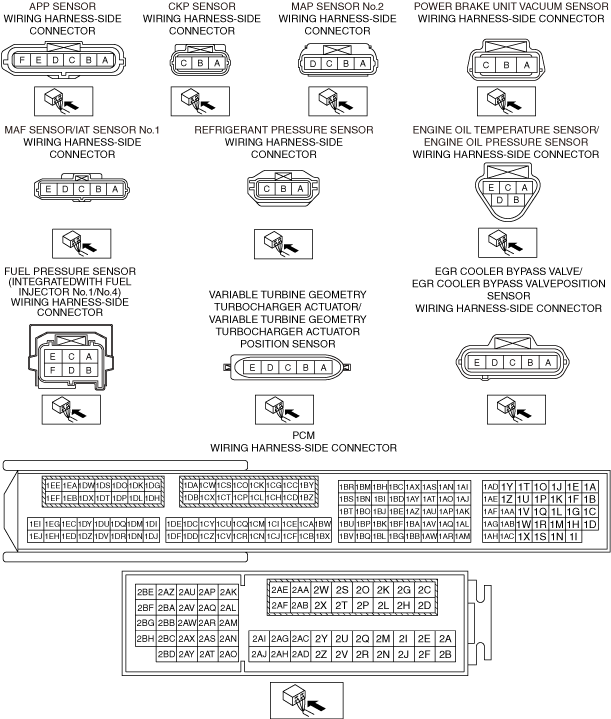

• Verify that the APP sensor, CKP sensor, MAP sensor No.2, engine oil temperature sensor/engine oil pressure sensor, MAF sensor/IAT sensor No.1, power brake unit vacuum sensor, Refrigerant pressure sensor, fuel pressure sensor (fuel injector No.1, 4 integrated), variable turbine geometry turbocharger actuator/variable turbine geometry turbocharger actuator position sensor, or EGR cooler bypass valve/EGR cooler bypass valve position sensor connector is disconnected.

• Inspect for continuity between the following terminals (vehicle wiring harness side) and body ground.

-

― APP sensor terminal A

― CKP sensor terminal A

― MAP sensor No.2 terminal C

― Engine oil temperature sensor/engine oil pressure sensor terminal A

― MAF/IAT sensor No.1 terminal D

― Power brake unit vacuum sensor terminal A

― Refrigerant pressure sensor terminal A

― Fuel pressure sensor (integrated with fuel injector No.1) terminal C

― Fuel pressure sensor (integrated with fuel injector No.4) terminal C

― Variable turbine geometry turbocharger actuator/variable turbine geometry turbocharger actuator position sensor terminal E

― EGR cooler bypass valve/EGR cooler bypass valve position sensor terminal B

• Is there continuity?

|

Yes

|

• Refer to the wiring diagram and verify if there is a common connector between the following terminals.

-

― APP sensor terminal A and PCM terminal 2AM

― CKP sensor terminal A and PCM terminal 1J

― MAP sensor No.2 terminal C and PCM terminal 1CN

― Engine oil temperature/engine oil pressure sensor terminal A and PCM terminal 1DN

― MAF/IAT sensor No.1 terminal D and PCM terminal 2AC

― Power brake unit vacuum sensor terminal C and PCM terminal 2BB

― Refrigerant pressure sensor terminal C and PCM terminal 2BB

― Fuel pressure sensor (integrated with fuel injector No.1) terminal C and PCM terminal 1M

― Fuel pressure sensor (integrated with fuel injector No.4) terminal C and PCM terminal 1N

― Variable turbine geometry turbocharger actuator/variable turbine geometry turbocharger actuator position sensor terminal E and PCM terminal 1BE

― EGR cooler bypass valve/EGR cooler bypass valve position sensor terminal B and PCM terminal 1AU

If there is a common connector:

-

― Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

― Repair or replace the malfunctioning location.

If there is no common connector:

-

― Repair or replace the wiring harness which is shorted to ground.

• Go to the next step.

|

|

No

|

Go to the next step.

|

|

16

|

VERIFY THAT REPAIRS HAVE BEEN COMPLETED

• Reconnect all the disconnected connectors.

• Refer to the [MEMORY CLEARING PROCEDURE] and clear the DTC.

• Switch the ignition ON (engine off) and wait for 30 s.

• Display the DTCs using the M-MDS.

• Has DTC P0642:00 been recorded?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM, then go to the next step.

|

|

No

|

Go to the next step.

|

|

17

|

VERIFY OTHER DTCs

• Has any other DTC or pending code been stored?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|