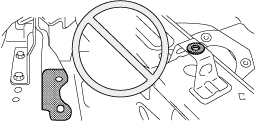

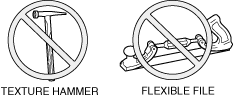

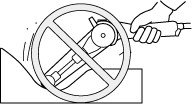

Prohibited

Use of mounted dust collector and grinder equipped with dust collector bag prohibited

Reason

To prevent explosion and ignition, caused when aluminum dust scatters and becomes suspended in the air and mixed with oxygen and an ignition source, from occurring while cleaning the dust collector filter and the dust collector bag of the grinder.

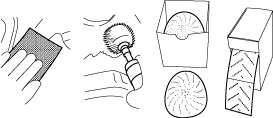

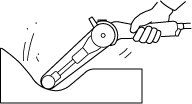

Prohibited

Cleaning aluminum dust with water prohibited

Reason

To prevent ignition caused when aluminum dust and water mix.

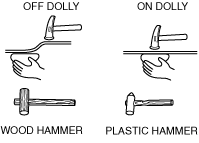

Implementation item

Use an explosion-resistant aluminum dust collector which can dispose aluminum dust in paper bag.

Reason

To prevent aluminum dust from scattering and becoming suspended in the air, and to avoid mixing it with water.

To prevent static electricity from occurring when dust is suctioned.

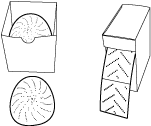

Implementation item

Temporarily store aluminum dust in a plastic bag and in a covered container so that the contents do not get wet from rain even if it is kept outdoors.

Reason

To prevent aluminum dust from getting wet when disposing it outdoors.

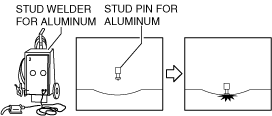

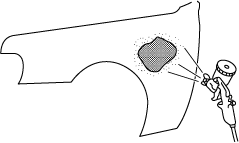

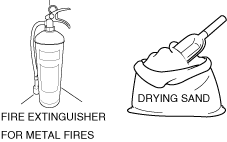

Implementation item

Always perform repair work after stationing a fire extinguisher for metal fires and drying sand in the work booth for aluminum.

Reason

To prevent a secondary accident caused by drainage or use of general fire extinguisher.