ENGINE [SKYACTIV-G 2.5T]

id0100000002s4

Special Features

• For SKYACTIV-G 2.5T, the following has been implemented to lower fuel consumption.

-

― Sliding resistance*1 reduction

-

• Rocker arm (with built-in needle roller bearing) adopted for cam-contact area

• Reduced valve spring load

• Narrowed down crankshaft journal

• Optimized piston skirt shape

• Lowered piston ring tension

• Lowered drive belt tension

• Suppressed chain tensioner load by stabilized timing chain behavior

• Oil shower pipe adopted

― Mechanical resistance loss reduction

-

• Optimized oil passage

• Optimized oil pump shape

• Engine oil variable control adopted

― Pumping loss*2 reduction

-

• Variable valve timing mechanism adopted on both intake and exhaust sides for fine control of exhaust amount and internal EGR volume

― Weight reductions

-

• Hard-plastic intake manifold adopted

• Exhaust manifold integrated cylinder head adopted

― Heat loss reduction

-

• Water jacket spacer adopted

― Cooling loss reduction in early stage of combustion

-

• Piston cavity adopted

― Cooling efficiency improvement

-

• Air seal cowl adopted

• Optimized cooling fan shape

• Optimized engine coolant passage

• Optimized water pump impeller shape

― Combustion efficiency improvement

-

• Multiple hole-type fuel injectors adopted

• High-pressure fuel pump adopted

• The HLA has been adopted to achieve the maintenance-free valve clearance.

• 4-3-1 type exhaust passages have been adopted to improve the acceleration/environmental performance.

• L-jetronic*3 and D-jetronic*4 types have been adopted for the intake air amount measurement to achieve stable combustion free from abnormal combustion.

-

― MAF sensor adopted

― MAP sensor adopted

― IAT sensor No.1 and No.2 adopted

― Boost pressure sensor and boost air temperature sensor adopted

• An ejector which can recirculate the evaporative gas in all engine ranges (boost range from non-boost range) has been adopted to improve the emission performance.

• To improve the fuel economy and emission performance, an electric variable valve timing control has been adopted for the intake side, and a hydraulic variable valve timing control for the exhaust side. The electric type is adopted for the intake side to achieve expanded valve overlap and delayed closing of the intake valve (enlarged intake valve opening angle).

Intake side: Electric variable valve timing control

-

― Intake CMP sensor adopted

― Electric variable valve timing motor/driver adopted

― Electric variable valve timing relay adopted

Exhaust side: Hydraulic variable valve timing control

-

― Exhaust CMP sensor adopted

• Engine oil variable control has been adopted to reduce the oil pump operation load on the engine.

-

― Engine oil solenoid valve adopted

• With the adoption of fuel pump control, fuel pump power consumption has been reduced to improve fuel economy.

-

― Fuel pump control module adopted

• Boost pressure control has been adopted to improve fuel economy/environmental performance/low-speed torque.

-

― Dynamic pressure turbo adopted

• To decrease generator operation loss, i-ELOOP has been adopted which generates electricity from energy occurring when the vehicle decelerates. (With i-ELOOP) (See:

i-ELOOP [i-ELOOP].)

-

― DC-DC converter (i-ELOOP) adopted

• Generator output control has been adopted to improve fuel economy/idling stability.

-

― A current sensor adopted (With i-stop system)

• An exhaust gas recirculation (EGR) system has been adopted to achieve cleaner exhaust emissions and improve fuel economy.

• To improve engine reliability, an ion sensor has been adopted which detects pre-ignition.

• LIN communication has been adopted to the current sensor to realize wiring harness simplification. (With i-stop system)

• i-stop control has been adopted to improve fuel efficiency, and reduce exhaust gas and idling noise. (With i-stop system)

*1 :Resistance (friction force) which occurs when objects slide. The larger the sliding resistance, the greater the energy loss.

*2 :Energy loss due to resistance in each part during intake/exhaust process is called pumping loss.

*3 :The intake air amount is directly detected by measuring the amount of intake air flow using the MAF sensor.

*4 :The intake air amount is detected indirectly by measuring the intake manifold pressure (pressure between downstream of the turbocharger and intake manifold) using the MAP sensor and boost pressure sensor.

Specification

|

Item

|

Specification

|

|

MECHANICAL

|

|

Type

|

Gasoline, 4-cycle

|

|

Cylinder arrangement and number

|

In-line, 4-cylinder

|

|

Combustion chamber

|

Pentroof

|

|

Valve system

|

DOHC, timing chain driven, 16 valves

|

|

Displacement

|

(ml {cc})

|

2,488 {2,488}

|

|

Bore × stroke

|

(mm {in})

|

89.0 × 100 {3.50 × 3.94}

|

|

Compression ratio

|

10.5:1

|

|

Valve timing

|

IN

|

Open

|

(°)

|

BTDC 50—ATDC 24

|

|

Close

|

(°)

|

ABDC 26—ABDC 100

|

|

EX

|

Open

|

(°)

|

BBDC 50—BBDC 5

|

|

Close

|

(°)

|

ATDC 2—ATDC 47

|

|

LUBRICATION SYSTEM

|

|

Type

|

Force-fed type

|

|

Oil pressure (reference value)

[Oil temperature: 80—90 °C {176—194 °F}, coolant temperature: 80—90 °C {176—194 °F}]

|

(kPa {kgf/cm2, psi}[rpm])

|

Lo: 135—165 {1.38—1.68, 19.6—25.9} [1,500]

Hi: 225—275 {2.30—2.80, 32.7—39.8} [4,500]

|

|

Oil pump

|

Type

|

Vane pump type

|

|

Oil filter

|

Type

|

Full-flow

|

|

Bypass pressure

|

(kPa {kgf/cm2, psi})

|

140—180 {1.43—1.83, 20.4—26.1}

|

|

Oil capacity (approx. quantity)

|

Oil replacement

|

(L {US qt, lmp qt})

|

4.6 {4.9, 4.0}

|

|

Oil and oil filter replacement

|

(L {US qt, lmp qt})

|

4.8 {5.1, 4.2}

|

|

Total (dry engine)

|

(L {US qt, lmp qt})

|

5.9 {6.2, 5.2}

|

|

COOLING SYSTEM

|

|

Type

|

Water-cooled, Electromotive

|

|

Water pump

|

Type

|

Centrifugal, V-ribbed belt-driven

|

|

Thermostat

|

Type

|

Wax type

|

|

Opening temperature

|

(°C {°F})

|

Australian, Taiwan specs.: 86.5—89.5 {188—193}

Except Australian, Taiwan specs.: 80.5—83.5 {177—182}

|

|

Full-open temperature

|

(°C {°F})

|

Australian, Taiwan specs.: 100 {212}

Except Australian, Taiwan specs.: 95 {203}

|

|

Full-open lift

|

(mm {in})

|

8.5 {0.33} or more

|

|

Radiator

|

Type

|

Corrugated fin type

|

|

Cooling system cap

|

Valve opening pressure

|

(kPa {kgf/cm2, psi})

|

93.2―122.6 {0.951―1.250, 13.6―17.7}

|

|

Cooling fan type

|

Type

|

Electric type

|

|

Number of blades

|

8

|

|

Outer diameter

|

(mm {in})

|

440 {17.3}

|

|

Cooling fan motor output

|

(W)

|

600

|

|

FUEL SYSTEM

|

|

Fuel injector

|

Type

|

High resistance

|

|

Fuel supply method

|

Top-feed

|

|

Drive types

|

Electronic type

|

|

Fuel pump unit discharge pressure

|

(kPa {kgf/cm2, psi})

|

Max. 700 {7.14, 102}

|

|

Fuel pump

|

Type

|

Electric type

|

|

Fuel tank

|

Capacity

|

(L {US gal, lmp gal})

|

2WD: 72.0 {19.0, 15.8}

4WD: 74.0 {19.5, 16.3}

|

|

EMISSION SYSTEM

|

|

Catalyst

|

Type

|

WU-TWC (monolith)

TWC (monolith)

|

|

EVAP control system

|

Type

|

Charcoal canister type

|

|

PCV system

|

Type

|

Closed type

|

|

CHARGING SYSTEM

|

|

Battery

|

Voltage

|

(V)

|

12

|

|

Type

(with i-stop)

|

Q-85

|

|

Type and capacity

(without i-stop)

|

(A·h/20HR)

|

55D23L (60)

75D23L (65)

|

|

Generator

|

Output

|

(V-A)

|

12-150

|

|

IGNITION SYSTEM

|

|

Ignition system

|

Type

|

SEI

|

|

Spark advance

|

Electronic

|

|

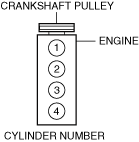

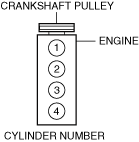

Firing order

|

1—3—4—2 (all cylinders independent firing)

|

|

|

Spark plug

|

Type

|

PY8V-18-110

|

|

STARTING SYSTEM

|

|

Starter

|

Type

|

Coaxial reduction

|

|

Output

|

(kW)

|

1.4

|

|

CONTROL SYSTEM

|

|

i-stop OFF switch

|

ON/OFF type switch

|

|

MAF sensor

|

Hot film

|

|

IAT sensor No.1

|

Thermistor

|

|

IAT sensor No.2

|

Thermistor

|

|

MAP sensor

|

Piezoresistance

|

|

TP sensor

|

Hall element

|

|

APP sensor

|

Electromagnetic induction action applied to non-contact type

|

|

CKP sensor

|

Magnetic resistance element

|

|

Intake CMP sensor

|

Magnetic resistance element

|

|

Exhaust CMP sensor

|

Magnetic resistance element

|

|

ECT sensor

|

Thermistor

|

|

BARO sensor

|

Piezoelectric element

|

|

High fuel pressure sensor

|

Distortion gauge

|

|

Low fuel pressure sensor

|

Semiconductor strain gauge

|

|

KS

|

Piezoelectric element

|

|

Current sensor

|

Voltage detecting area/Current detecting area/Temperature detecting area

|

|

A/F sensor

|

Zirconium element

|

|

HO2S

|

Zirconia element

|

|

Fuel tank pressure sensor

|

Piezoelectric element

|

|

Boost pressure sensor

|

Piezoresistance

|

|

Boost air temperature sensor

|

Thermistor

|

|

Fuel temperature sensor

|

Thermistor

|

|

Exhaust gas pressure sensor

|

Piezoelectric element

|

|

Engine oil temperature sensor

|

Thermistor

|

|

Engine oil pressure sensor

|

Semiconductor strain gauge

|

|

Wastegate valve position sensor

|

Hall element

|

|

Engine oil level sensor

|

Piezoelectric element

|

|

Power brake unit vacuum sensor

|

Piezoelectric element

|

|

Ion sensor

|

Ion detection circuit

|

|

Fuel tank pressure sensor

|

Piezoelectric element

|

Compression pressure

Engine oil [European, Taiwan specs.]

|

Recommended engine oil

|

Alternative engine oil

|

|

Mazda Original Oil Supra 0W-30

|

Mazda Original Oil Ultra 5W-30

|

API SN or higher, or ACEA A5/B5

0W-30, 5W-30

|

Engine oil [Except European, Taiwan specs.]

|

Item

|

Specifications

|

|

Grade

|

API SM or higher, or ILSAC GF-4 or higher

|

|

Viscosity (SAE)

|

0W-30, 5W-30, 10W-30

|

Engine coolant capacity (approx. quantity)

|

Item

|

Capacity

|

|

Australian specs.

|

10 L {11 US qt, 8.8 Imp qt}

|

|

Azerbaijan, Kazakhstan, Armenia, Georgia, Russia, Belarus, Ukraine, Mongolia, Taiwan

|

9.9 L {10 US qt, 8.7 Imp qt}

|

|

Except above

|

L.H.D.

|

9.8 L {10 US qt, 8.6 Imp qt}

|

|

R.H.D.

|

9.9 L {10 US qt, 8.7 Imp qt}

|

Fuel type

|

Fuel

|

Research Octane Number

|

Country

|

|

Premium unleaded fuel

|

95 or above

|

Antigua, Armenia, Aruba, Azerbaijan, Barbados, Belarus, Bolivia, Brunei, Georgia, Grenada, Guatemala, Honduras, Indonesia, Jamaica, Kazakhstan, Lebanon, Libya, Macau, Madagascar, Malaysia, Mauritius, Mongolia, Morocco, New Caledonia, Nicaragua, Russia, Seychelles, Singapore, ST. Lucia, St. Martin, ST. Vincent, Surinam, Tahiti, Taiwan, Tunisia, UAE, Ukraine, Uruguay, Vanuatu

|

|

Regular unleaded fuel (Conforming to Fuel Quality Standards Act 2000)*1

|

92 or above

|

Egypt, Myanmar

|

|

90 or above

|

Australia, New Zealand, Angola, B. Virgin, Bahrain, Burundi, Cambodia, Cameroon, Chile, Colombia, Commonwealth of Dominica, Costa Rica, Curacao, Dominican Republic (LHD), Ecuador, El Salvador, Fiji, Gabon, Ghana, Haiti, Iraq, Ivory Coast, Jordan, Kenya, Kuwait, Laos, Marshall Islands, Mozambique, Nepal, Nigeria, Oman, Panama, Papua New Guinea, Peru, Qatar, Saudi Arabia, Sri Lanka, Tanzania, The Philippines, Trinidad and Tobago, USTT*2, Vietnam, Zimbabwe

|

*1 :Australian

*2 :Republic of Palau & Federated States of Micronesia