|

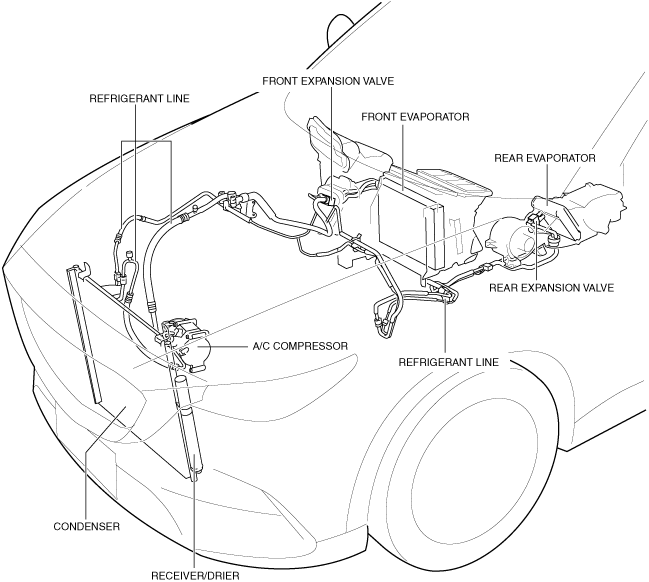

REFRIGERANT SYSTEM

id071100000900

Outline

Function

Structure/Construction

Structural view

L.H.D.

ac9wzn00001069

|

R.H.D.

ac9wzn00001070

|

Operation

1. When there is no energization to the starter (A/C relay off) (1), the pressure plate and A/C compressor pulley do not engage.

2. When there is energization to the starter (A/C relay on) (2), the magnetic clutch of the starter operates and the pressure plate and A/C compressor pulley engage (3).

3. The engine power (4) from the drive belt is transmitted (5) to the A/C compressor via the pressure plate from the A/C compressor pulley.

ac9wzn00001071

|

4. When the magnetic clutch engages, the swash plate in the A/C compressor rotates. The piston moves reciprocally by the rotation of the swash plate, compression in the cylinder is generated, and refrigerant intake, compression, and discharge are performed.

5. When the piston of the A/C compressor moves downward, the suction valve opens and low temperature and low pressure gaseous refrigerant is introduced (6) into the cylinder.

6. When the piston of the A/C compressor reaches the BDC, refrigerant charging is completed (7) and the suction valve closes.

7. When the piston of the A/C compressor moves upward, the gaseous refrigerant in the cylinder is pressurized (8).

8. The compressed gaseous refrigerant presses open the discharge valve and the A/C compressor discharges (9) the high-temperature and highly pressurized gaseous refrigerant from the cylinder.

9. The high temperature, high pressure gaseous refrigerant is sent (10) to the condenser.

ac9wzn00001072

|

10. The high temperature, high pressure gaseous refrigerant is circulated (11) inside the side of the condenser.

11. When the airflow from the exterior contacts the condenser fins, the heat in the circulating refrigerant is released through heat exchange, and the once high temperature, high pressure gaseous refrigerant becomes a low temperature, high pressure liquid refrigerant (12).

12. The low temperature, high pressure liquid refrigerant is purified and dehumidified by the receiver/drier and sent to the front/rear expansion valve (13).

ac9wzn00001073

|

13. The low temperature, high pressure liquid refrigerant is depressurized by the front/rear expansion valve and converted to a mist which is sent (14) to the front/rear evaporator.

14. The liquid refrigerant, now in a mist state, is atomized in the front/rear evaporator and becomes (15) a low temperature, low pressure gaseous refrigerant, and the front/rear evaporator is cooled by the surrounding heat being drawn out (latent heat) when the liquid is atomized.

15. The front/rear expansion valve adjusts the liquid refrigerant flow volume to the front/rear evaporator according to the gaseous refrigerant temperature (16) circulating from the front/rear evaporator to the condenser.

16. The low temperature, low pressure gaseous refrigerant is sent to the A/C compressor and circulates (17) the refrigerant cycle.

ac9wzn00001074

|

17. The airflow passing through the cooled front/rear evaporator is cooled via heat exchange, the moisture in the air is condensed in the front/rear evaporator, and dehumidified.

ac9wzn00001075

|