|

ON-BOARD DIAGNOSTIC TEST [MZI-3.7 (PCM CONNECTOR (3 TYPES))]

id0102e4801000

DTC Reading Procedure

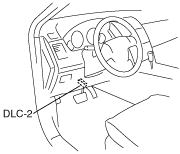

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Verify the DTC according to the directions on the M-MDS screen.

5. After completion of repairs, clear all DTCs stored in the PCM, while referring to “AFTER REPAIR PROCEDURE“.

Pending Trouble Code Access Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the pending trouble codes according to the directions on the M-MDS screen.

Freeze Frame PID Data Access Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the freeze frame PID data according to the directions on the M-MDS screen.

On-Board System Readiness Tests Access Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Then, select the “***SUP” and “**EVAL” PIDs in the PID selection screen.

4. Monitor those PIDs and check it system monitor is completed.

PID/DATA Monitor and Record Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the PID from the PID table.

4. Verify the test results according to detections on the screen.

PID/Data Monitor Table

The Mazda Modular Diagnostic System (M-MDS)

|

PID Name |

Description |

Unit |

|||

|---|---|---|---|---|---|

|

AAT

|

Ambient air temperature

|

°C

|

°F

|

||

|

AC_PRES

|

Refrigerant pressure sensor

|

V

|

|||

|

kPa

|

psi

|

Bar

|

|||

|

AC_REQ

|

A/C request signal

|

Off/On

|

|||

|

ACCS

|

A/C relay

|

Off/On

|

|||

|

ALTF

|

Generator field coil control duty value

|

%

|

|||

|

APP

|

Accelerator pedal position

|

%

|

|||

|

APP1

|

APP sensor No.1

|

%

|

|||

|

V

|

|||||

|

APP2

|

APP sensor No.2

|

%

|

|||

|

V

|

|||||

|

ARPMDES

|

Target engine speed

|

RPM

|

|||

|

AXLE

|

Axle ratio

|

—

|

|||

|

BARO

|

Barometric pressure

|

kPa

|

psi

|

Bar

|

|

|

BOO

|

Brake switch

|

Off/On

|

|||

|

BPA

|

Brake pressure applied switch

|

Off/On

|

|||

|

CATT11_DSD

|

Estimated catalytic converter temperature (RH)

|

°C

|

°F

|

||

|

CATT21_DSD

|

Estimated catalytic converter temperature (LH)

|

°C

|

°F

|

||

|

CHRGLP

|

Generator warning light

|

Off/On

|

|||

|

CHT

|

CHT sensor

|

°C

|

°F

|

||

|

V

|

|||||

|

ECT

|

Engine coolant temperature

|

°C

|

°F

|

||

|

EQ_RAT11

|

Equivalence ratio (lambda) A/F sensor (RH)

|

—

|

|||

|

EQ_RAT11_DSD

|

Desired equivalence ratio (lambda)

|

—

|

|||

|

EQ_RAT12

|

Equivalence ratio (lambda) HO2S (RH)

|

—

|

|||

|

ETC_ACT

|

Electronic throttle control actual

|

°

|

|||

|

ETC_DSD

|

Electronic throttle control desired

|

%

|

|||

|

°

|

|||||

|

EVAPCP

|

Purge solenoid valve duty value

|

%

|

|||

|

EVAPCV

|

CV solenoid valve

|

Off/On

|

|||

|

FAN_DUTY

|

Cooling fan control

|

%

|

|||

|

FCL

|

Fuel cap warning light

|

Off/On

|

|||

|

FLI

|

Fuel level

|

%

|

|||

|

FP

|

Fuel pump relay

|

Off/On

|

|||

|

FPM

|

Fuel pump monitor

|

Off/On

|

|||

|

FTP

|

Fuel tank pressure sensor

|

V

|

|||

|

FUELSYS

|

Fuel system loop status (RH)

|

OL/CL/OL-Drive/OL-Fault/CL-Fault

|

|||

|

GENVDSD

|

Generator voltage desired

|

V

|

|||

|

HTR11

|

A/F sensor heater (RH)

|

Off/On

|

|||

|

%

|

|||||

|

HTR12

|

HO2S heater (RH)

|

Off/On

|

|||

|

%

|

|||||

|

HTR21

|

A/F sensor heater (LH)

|

Off/On

|

|||

|

HTR22

|

HO2S heater (LH)

|

Off/On

|

|||

|

IAT

|

IAT sensor

|

°C

|

°F

|

||

|

V

|

|||||

|

INGEAR

|

Load/no load condition

|

Off/On

|

|||

|

INJ_PWR

|

Injector power monitor

|

V

|

|||

|

IVS

|

CTP condition

|

Off Idle/Idle

|

|||

|

KNOCKR

|

Knocking retard

|

°

|

|||

|

LOAD

|

Engine load

|

%

|

|||

|

LONGFT1

|

Long term fuel trim (RH)

|

%

|

|||

|

LONGFT2

|

Long term fuel trim (LH)

|

%

|

|||

|

MAF

|

MAF sensor

|

g/s

|

|||

|

V

|

|||||

|

MIL_DIS

|

Travelled distance since the MIL illuminated

|

km

|

|||

|

O2S11

|

A/F sensor (RH)

|

V

|

|||

|

O2S12

|

HO2S (RH)

|

V

|

|||

|

O2S21

|

A/F sensor (LH)

|

V

|

|||

|

O2S22

|

HO2S (LH)

|

V

|

|||

|

PSP

|

PSP switch

|

Low/High

|

|||

|

RO2FT1

|

HO2S fuel trim (RH)

|

—

|

|||

|

RO2FT2

|

HO2S fuel trim (LH)

|

—

|

|||

|

RPM

|

Engine speed

|

RPM

|

|||

|

SC_CANCEL

|

Speed control cancel switch

|

Inactive/Active

|

|||

|

SC_OFF

|

Cruise control OFF switch

|

Inactive/Active

|

|||

|

SC_ON

|

Cruise control ON switch

|

Inactive/Active

|

|||

|

SC_RES

|

Cruise resume switch

|

Inactive/Active

|

|||

|

SC_SET-

|

Cruise coast switch

|

Inactive/Active

|

|||

|

SC_SET+

|

Cruise set/acceleration switch

|

Inactive/Active

|

|||

|

SCCS

|

Speed control command switch

|

V

|

|||

|

SHRTFT1

|

Short term fuel trim (RH)

|

%

|

|||

|

SHRTFT12

|

Short term fuel trim (HO2S) (RH)

|

%

|

|||

|

SHRTFT2

|

Short term fuel trim (LH)

|

%

|

|||

|

SHRTFT22

|

Short term fuel trim (HO2S) (LH)

|

%

|

|||

|

SPARKADV

|

Ignition timing

|

°

|

|||

|

TIRESIZE

|

Tire revolution per mile

|

—

|

|||

|

TP REL

|

Relative throttle position

|

%

|

|||

|

TP1

|

TP sensor No.1

|

%

|

|||

|

V

|

|||||

|

TP2

|

TP sensor No.2

|

%

|

|||

|

V

|

|||||

|

VPWR

|

Battery voltage

|

V

|

|||

|

VSS

|

Vehicle speed

|

KPH

|

|||

|

VT ACT1

|

Actual valve timing (RH)

|

°

|

|||

|

VT ACT2

|

Actual valve timing (LH)

|

°

|

|||

|

VT DIFF1

|

Difference between target and actual valve timing (RH)

|

°

|

|||

|

VT DIFF2

|

Difference between target and actual valve timing (LH)

|

°

|

|||

|

VT DUTY1

|

Oil control valve duty value (RH)

|

%

|

|||

|

VT DUTY2

|

Oil control valve duty value (LH)

|

%

|

|||

|

VT_DSD

|

Desired intake camshaft position

|

°

|

|||

Diagnostic Monitoring Test Results Access Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Verify the PID data according to the directions on the screen.

Active Command Modes Procedure

1. Connect the M-MDS to the DLC-2.

ac9wzw00002402

|

2. After the vehicle is identified, select the following items from the initial screen of the M-MDS.

3. Select the simulation items from the PID table.

4. Perform the simulation function, inspect the operations for each parts.