5

Liftgate reverses and PLG buzzer sounds 3 times, while auto open/close function

DESCRIPTION

• Liftgate reverses while auto open or close operation without object is pinched, the switches (PLG front switch, PLG rear switch and/or transmitter) are operated and/or liftgate outer handle is operated.

• PLG buzzer sounds 3 times when the liftgate reverses.

POSSIBLE CAUSE

• Misdetection of liftgate pinch

-

― Malfunction in liftgate link mechanism

-

• Stay dumper malfunction

― Malfunction in PLG link mechanism-

• PLG arm malfunction• PLG slider malfunction• Torque cable malfunction

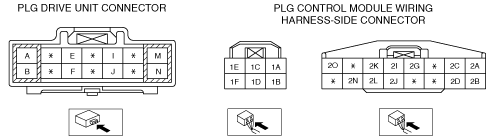

― PLG control module does not receive rotation sensor signal properly.-

• Rotation sensor malfunction (missing pulse)• Temporary open or short to POWER/ground/other harness in wiring between PLG drive unit and PLG control module• Malfunction in PLG drive unit (motor or clutch malfunction)

-

• PLG control module malfunction