|

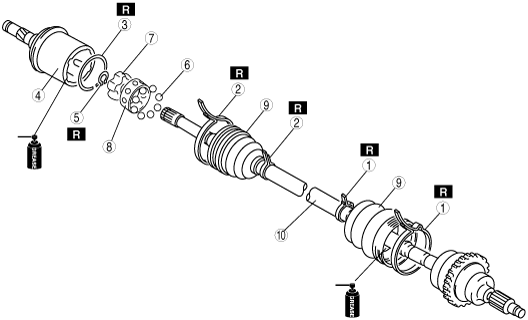

REAR DRIVE SHAFT DISASSEMBLY/ASSEMBLY

id031300800700

1. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

ac9uuw00002478

|

|

1

|

Boot band (wheel side)

|

|

2

|

Boot band (differential side)

|

|

3

|

Clip

(See Clip Disassembly Note)

|

|

4

|

Outer ring

|

|

5

|

Snap ring

|

|

6

|

Balls

|

|

7

|

Inner Ring

|

|

8

|

Cage

|

|

9

|

Boot

(See Boot Assembly Note)

|

|

10

|

Drive shaft, joint component

|

Boot Band (Wheel Side) Disassembly Note

1. Remove the boot clamp with end clamp pliers as shown and discard the clamp.

ac9uuw00002479

|

Boot Band (Differential Side) Disassembly Note

1. Pry up the locking clips using a screwdriver.

ac9uuw00002480

|

2. Pull back the end of the band.

Clip Disassembly Note

1. Mark the drive shaft and outer ring for proper assembly.

ac9uuw00002481

|

2. Remove the clip.

Snap Ring Disassembly Note

1. Mark the drive shaft end and inner ring for proper reassembly.

ac9wzw00000626

|

2. Remove the snap ring using snap‐ring pliers.

Balls, Inner Ring, Cage Disassembly Note

1. Mark the inner ring and cage for proper reassembly.

2. Turn the cage approx. 22.5°and pull the cage and balls from the inner ring.

ac9uuw00002483

|

Boot Assembly Note

1. Fill the wheel side boot with the specified grease.

2. With the splines of the shaft wrapped in tape, install the boot.

3. Remove the tape.

Cage, Inner Ring, Balls, Snap Ring Assembly Note

1. Align the marks and install the balls and cage to the inner ring in the direction shown in the figure.

acxuuw00001299

|

2. Align the marks and install the inner ring to the shaft.

3. Install a new snap ring.

Outer Ring, Clip Assembly Note

1. Fill the outer ring and boot (differential side) with the specified grease.

2. Align the marks, and install the outer ring on to the shaft.

ac9uuw00002481

|

3. Install a new clip to the outer ring clip groove.

4. Install the boot.

5. Release any trapped air from the boots by carefully lifting up the small end of each boot with a cloth wrapped screwdriver.

ac9uuw00002484

|

6. Set the drive shaft to the standard length.

7. Verify that the drive shaft length is within the standard.

Boot Band (Differential Side) Assembly Note

1. Fold the band in the direction opposite to the forward revolving direction of the drive shaft and use pliers to pull it tight.

ac9uuw00002485

|

2. Lock the end of the band by bending the locking clips.

Boot Band (Wheel Side) Assembly Note

1. Adjust clearance A by turning the adjusting bolt of the SST.

ac9uuw00002486

|

2. Crimp the wheel side small boot band using the SST. Verify that clearance B is within the specification.

ac9uuw00002487

|

3. Verify that the boot band does not protrude from the boot band installation area.

4. Fill the boot with the repair kit grease.

5. Adjust clearance A by turning the adjusting bolt of the SST.

6. Crimp the wheel side big boot band using the SST.

7. Verify that clearance B is within the specification.

8. Verify that the boot band does not protrude from the boot band installation area.