|

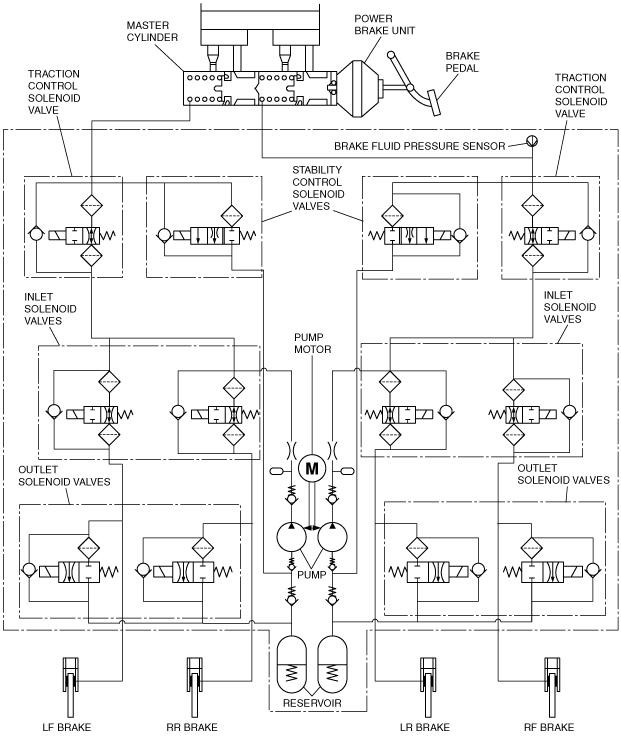

DSC/RSC HU PART CONSTRUCTION/OPERATION

id041800818200

Construction

Function of main component parts

|

Part name |

Function |

|---|---|

|

Inlet solenoid valve

|

• Adjusts the fluid pressure in each brake system according to DSC/RSC HU/CM signals.

|

|

Outlet solenoid valve

|

• Adjusts the fluid pressure in each brake system according to DSC/RSC HU/CM signals.

|

|

Stability control solenoid valve

|

• Switches the brake hydraulic circuits during and according to normal braking, ABS and EBD control, TCS control and DSC control, RSC control.

|

|

Traction control solenoid valve

|

• Switches the brake hydraulic circuits during and according to normal braking, ABS and EBD control, TCS control and DSC control, RSC control.

|

|

Reservoir

|

• Temporarily stores brake fluid from the caliper piston to ensure smooth pressure reduction during ABS and EBD control, TCS control and DSC control, RSC control.

|

|

Pump

|

• Returns the brake fluid stored in the reservoir to the master cylinder during ABS and DSC control, RSC control.

• Increases brake fluid pressure and sends brake fluid to each caliper piston during TCS control and DSC control, RSC control.

|

|

Pump motor

|

• Operates the pump according to DSC/RSC HU/CM signals.

|

Hydraulic circuit diagram

ac9uun00000488

|

Operation

During normal braking

Solenoid valve operation table

|

Traction control solenoid valve |

Stability control solenoid valve |

Inlet solenoid valve |

Outlet solenoid valve |

Pump motor, pump |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LF—RR |

RF—LR |

LF—RR |

RF—LR |

LF |

RF |

LR |

RR |

LF |

RF |

LR |

RR |

|

|

OFF (open)

|

OFF (closed)

|

OFF (open)

|

OFF (closed)

|

Stopped

|

||||||||

Hydraulic circuit diagram

ac9uun00000489

|

During ABS and EBD control

Solenoid valve operation table

|

|

Traction control solenoid valve |

Stability control solenoid valve |

Inlet solenoid valve |

Outlet solenoid valve |

Pump motor, pump |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LF—RR |

RF—LR |

LF—RR |

RF—LR |

LF |

RF |

LR |

RR |

LF |

RF |

LR |

RR |

||

|

During Pressure increase mode

|

OFF (open)

|

OFF (closed)

|

OFF (open)

|

OFF (closed)

|

Stopped

|

||||||||

|

During pressure maintain mode

|

OFF (open)

|

OFF (closed)

|

ON (closed)

|

OFF (closed)

|

Stopped

|

||||||||

|

During pressure reduction mode

|

OFF (open)

|

OFF (closed)

|

ON (closed)

|

ON (open)

|

Operating

|

||||||||

Hydraulic circuit diagram

ac9uun00000490

|

During DSC control (suppress oversteer tendency) and TCS control

Solenoid valve operation table

|

|

Traction control solenoid valve |

Stability control solenoid valve |

Inlet solenoid valve |

Outlet solenoid valve |

Pump motor, pump |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LF—RR |

RF—LR |

LF—RR |

RF—LR |

LF |

RF |

LR |

RR |

LF |

RF |

LR |

RR |

||

|

During pressure increase mode

|

ON

(closed)

|

OFF

(closed)

|

ON

(open)

|

ON

(closed)

|

OFF

(open)

|

ON

(closed)

|

OFF

(open)

|

OFF (closed)

|

Operating

|

||||

|

During pressure maintain mode

|

OFF

(open)

|

ON

(closed)

|

OFF (closed)

|

OFF

(open)

|

ON (closed)

|

ON (closed)

|

OFF

(open)

|

OFF (closed)

|

Operating

|

||||

|

During pressure reduction mode

|

OFF

(open)

|

ON

(closed)

|

OFF (closed)

|

OFF

(open)

|

ON (closed)

|

OFF

(open)

|

OFF

(closed)

|

ON

(open)

|

OFF

(closed)

|

OFF

(closed)

|

Operating

|

||

Hydraulic circuit diagram

ac9uun00000491

|

During DSC control (to suppress understeer tendency)

Solenoid valve operation table

|

|

Traction control solenoid valve |

Stability control solenoid valve |

Inlet solenoid valve |

Outlet solenoid valve |

Pump motor, pump |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LF—RR |

RF—LR |

LF—RR |

RF—LR |

LF |

RF |

LR |

RR |

LF |

RF |

LR |

RR |

||

|

During pressure increase mode

|

ON (closed)

|

OFF

(closed)

|

ON

(open)

|

OFF

(open)

|

ON

(closed)

|

OFF

(open)

|

OFF (closed)

|

Operating

|

|||||

|

During pressure maintain mode

|

OFF

(open)

|

ON

(closed)

|

OFF (closed)

|

OFF

(open)

|

ON (closed)

|

OFF

(open)

|

OFF (closed)

|

Operating

|

|||||

|

During pressure reduction mode

|

OFF

(open)

|

ON

(closed)

|

OFF (closed)

|

OFF

(open)

|

ON (closed)

|

OFF

(open)

|

OFF

(closed)

|

ON

(open)

|

OFF

(closed)

|

Operating

|

|||

Hydraulic circuit diagram

ac9uun00000492

|