|

CAN SYSTEM DESCRIPTION

id094000101000

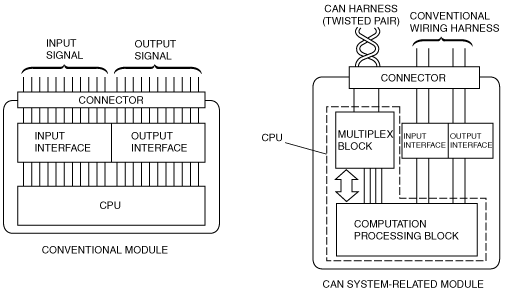

Mechanism of CAN System-Related Module

|

Component |

Function |

|

|---|---|---|

|

Electrical circuit

|

Supplies power to CPU and vicinity, and to input/output interface.

|

|

|

CPU

|

Computation processing block

|

Control function has been expanded, and when transmission is necessary, transmitted data is stored in a multiplex block. If a multiplex block receives a request to read stored data, transmitted data is read from the multiplex block.

|

|

Multiplex block

|

Transmits data received from bus line to computation processing block. In addition, sends transmitted data stored from computation processing block to bus line.

|

|

|

Input/Output interface

|

Electrically converts information signals from switches to, be input to CPU, and signals output from CPU for operating actuator or indicator lights.

|

|

acxuun00000506

|

Twisted Pair

acxuun00000507

|

Time Division Multiplex

acxuun00000508

|

Vehicle CAN System

acxuun00000509

|

CAN Signal-Chart (HS-CAN)

|

Signal |

Multiplex module |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

PCM |

TCM |

DSC/RSC HU/CM |

BCM |

4WD control module |

PLG control module |

SAS control module |

Keyless control module |

Instrument cluster |

Engine-off-natural-vacuum |

|

|

Immobilizer-related information

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

IN

|

–

|

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

–

|

|

|

Engine torque

|

OUT

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Engine load

|

OUT

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Engine torque

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

OUT

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

|

Brake switch

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Malfunction of evaporative emission control system-related information

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

|

|

FUEL_FLOW

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

MIL on request

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

|

Cruise control system-related information

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

|

ETC warning light on request

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Electronic throttle control (ETC) status

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Generator warning light on request

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Fuel cap warning light on request

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Intake air temperature

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Engine coolant temperature

|

OUT

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

ATX gear position/selector lever position

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Steering angle/steering angle sensor status

|

–

|

–

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Door switch status (LF, RF, LR, RR, liftgate)

|

–

|

–

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Key reminder switch status

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Turn indicator light on request

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Turn indicator light on request

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Brake fluid level

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Oil pressure switch status

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Washer fluid level sensor status

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Door lock status

|

–

|

–

|

–

|

OUT

|

–

|

IN

|

–

|

–

|

–

|

–

|

|

Torque down request

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

ATF temperature

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

ATX gear position/selector lever position

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Travelled distance

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Brake fluid pressure

|

–

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Torque down request

|

IN

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

Brake system status (EBD/ABS/DSC/RSC)

|

–

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

IN

|

IN

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

|

IN

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

|

Wheel speed (LF, RF, LR, RR)

|

IN

|

IN

|

OUT

|

IN

|

IN

|

IN

|

–

|

–

|

–

|

–

|

|

IN

|

IN

|

OUT

|

IN

|

IN

|

–

|

–

|

–

|

–

|

–

|

|

|

Brake system warning light on request

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

ABS warning light on request

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Tire circumference (front/rear)

|

IN

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

DSC indicator light on request

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

TCS OFF light on request

|

–

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

|

Security light on request

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

IN

|

–

|

|

Keyless warning buzzer on request

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

IN

|

–

|

|

Keyless indicator light on request

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

IN

|

–

|

|

Keyless warning light on request

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

–

|

|

PLG operation request

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

OUT

|

–

|

–

|

|

–

|

–

|

–

|

IN

|

–

|

OUT

|

–

|

–

|

–

|

–

|

|

|

–

|

–

|

–

|

IN

|

–

|

OUT

|

–

|

IN

|

IN

|

–

|

|

|

Buckle switch status

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

IN

|

–

|

|

Passenger sensing system status

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

IN

|

–

|

|

Air bag system warning light on request

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

IN

|

–

|

|

–

|

–

|

–

|

–

|

–

|

–

|

IN

|

–

|

OUT

|

–

|

|

|

Air bag system warning buzzer on status

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

IN

|

–

|

|

4WD system status

|

–

|

–

|

IN

|

–

|

OUT

|

–

|

–

|

–

|

–

|

–

|

|

–

|

–

|

–

|

–

|

OUT

|

–

|

–

|

–

|

IN

|

–

|

|

|

Fuel tank level

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

IN

|

|

IN

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

|

|

Brake fluid level

|

–

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

|

Parking brake switch status

|

IN

|

–

|

IN

|

–

|

IN

|

–

|

–

|

–

|

OUT

|

–

|

|

Ignition key position

|

IN

|

–

|

IN

|

–

|

–

|

–

|

–

|

–

|

OUT

|

–

|

CAN Signal-Chart (MS-CAN)

|

Signal |

Multiplex module |

||

|---|---|---|---|

|

Audio unit |

Audio amplifier |

Information display |

|

|

Audio status display request

|

OUT

|

–

|

IN

|

|

Ignition key position

|

OUT

|

–

|

IN

|

|

Drive information system data

|

OUT

|

–

|

IN

|

|

Buttons status

|

OUT

|

–

|

IN

|

|

Vehicle speed

|

OUT

|

IN

|

–

|

|

Audio system-related information

|

OUT

|

IN

|

–

|

|

IN

|

OUT

|

–

|

|

|

Beep sound request

|

IN

|

IN

|

OUT

|

On-Board Diagnostic Function

Block diagram

HS-CAN

ac9wzn00000166

|

MS-CAN

ac9wzn00000167

|

Failure detection function

Fail-safe function

Memory function

Self-malfunction diagnostic function

DTC table

|

DTC |

Malfunction location |

DTC output module |

|---|---|---|

|

U0073

|

CAN system communication error

|

• TCM

• DSC/RSC HU/CM

• BCM

• 4WD control module

• PLG control module

• SAS control module

• Keyless control module

• Instrument cluster

|

|

U0100

|

Communication error to PCM

|

• TCM

• DSC/RSC HU/CM

• 4WD control module

• PLG control module

• SAS control module

• Keyless control module

• Instrument cluster

|

|

U0101

|

Communication error to TCM

|

• PCM

• 4WD control module

• PLG control module

• Instrument cluster

|

|

U0114

|

Communication error to 4WD control module

|

• Instrument cluster

|

|

U0121

|

Communication error to DSC/RSC HU/CM

|

• TCM

• 4WD control module

• Instrument cluster

|

|

U0129

|

Communication error to DSC/RSC HU/CM

|

• PCM

|

|

U0140

|

Communication error to BCM

|

• TCM

• DSC/RSC HU/CM

• PLG control module

• Keyless control module

• Instrument cluster

|

|

U0151

|

Communication error to SAS control module

|

Instrument cluster

|

|

U0155

|

Communication error to instrument cluster

|

• PCM

• DSC/RSC HU/CM

• 4WD control module

• PLG control module

• SAS control module

|

|

U0184

|

Communication error to audio unit

|

Information display

|

|

U0214

|

Communication error to keyless control module

|

• PLG control module

• Instrument cluster

|

|

U0300

|

Internal control module software incompatibility

|

PCM

|

|

U0323

|

Communication error to instrument cluster

|

Keyless control module

|

|

U0415

|

Abnormal message from DSC/RSC HU/CM

|

TCM

|

|

U2023

|

Abnormal message from other modules

|

• DSC/RSC HU/CM

• Keyless control module

• Instrument cluster

|

|

U2510

|

Communication error to PCM

|

Instrument cluster

|

|

U2516

|

CAN system communication error

|

Information display

|

|

23:Er11

|

Communication error to audio amplifier

|

Audio unit (Touch panel type)

|

Narrowing down malfunction locations

Flowchart

ac9uun00000374

|

Example (PCM-related communication error)

1. DTCs for the PCM, DSC/RSC HU/CM and instrument cluster can be verified using the Mazda Modular Diagnostic System (M-MDS).

|

Module |

Displayed DTC |

Probable malfunction location |

|---|---|---|

|

PCM

|

U0155

|

Communication error between PCM and instrument cluster

|

|

DSC/RSC HU/CM

|

–

|

–

|

|

Instrument cluster

|

U0100

|

Communication error between instrument cluster and PCM

|

ac9uun00000373

|

2. If there is a communication error between the instrument cluster and PCM, even if the communication between the DSC/RSC HU/CM and the instrument cluster is normal, it is probable that there is a malfunction in the PCM or PCM-related wiring harnesses.