|

a30zzn00001213

EV SYSTEM OUTLINE

id300000000200

OUTLINE

Specification

|

Item |

Specification |

||

|---|---|---|---|

|

Electric motor

|

Model

|

MH

|

|

|

Type

|

AC cycle electric motor

(Permanent magnet type synchronous electric motor)

|

||

|

Maximum output

|

(kW)

|

107

|

|

|

Maximum torque

|

(Nm)

|

270

|

|

|

High voltage battery

|

Type

|

Lithium-ion battery

|

|

|

Quantity (module)

|

16

|

||

|

Battery total voltage

|

355 V

|

||

|

Connection type

|

Series

|

||

|

Capacity

|

(Ah)

|

100

|

|

|

Cooling type

|

Refrigerant type

|

||

|

Cooling system

|

Cooling type

|

Water-cooled type

|

|

|

Water pump

|

Type

|

Electric

|

|

|

Accelerator pedal position sensor

|

Hall element type

|

||

|

Electric motor temperature sensor

|

Thermistor type

|

||

|

Electric motor speed sensor

|

Resolver type

|

||

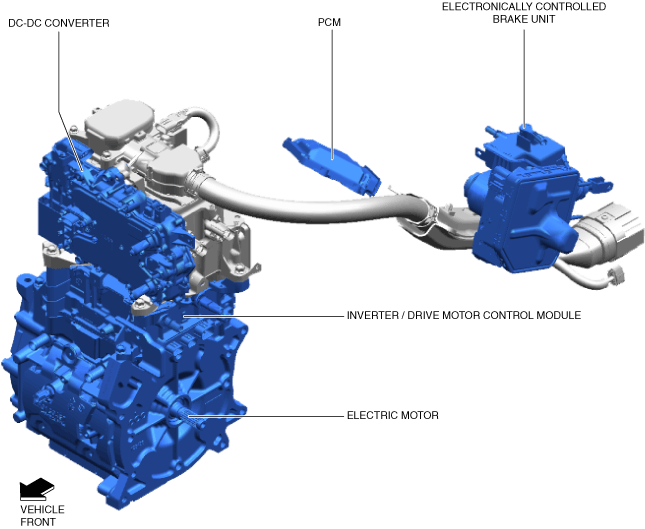

Structural view

L.H.D.

a30zzn00001213

|

R.H.D.

a30zzn00002251

|

a30zzn00001214

|

Component parts

|

Component parts |

Outline |

|---|---|

|

PCM

|

• Calculates drive force required by user and controls electric motor output.

• Monitors high voltage battery conditions (voltage, current, charging condition, and temperature).

• Controls DC-DC converter to supply power to vehicle's electrical devices.

• Controls coolant discharge amount of electric water pump.

• Controls cooling fan airflow volume.

• Determines insulation condition of high voltage circuit based on monitoring results of electrical leakage detection device in BECM.

|

|

Electric motor

|

• Generates drive force using electrical power from high voltage battery during driving.

• Acts as a regenerative brake during deceleration to recover vehicle’s kinetic energy.

|

|

Inverter

|

• Performs the followings by driving internal power transistors.

|

|

Drive motor control module

|

• Controls power transistors in inverter based on conditions of inverter and electric motor and electric motor requested torque from PCM.

• Detects conditions of electric motor and inverter, and transmits it to PCM.

|

|

DC-DC converter

|

• Steps down 355 V DC of high voltage battery to 14 V DC to supply power to accessories and to charge lead-acid battery.

|

|

High voltage battery

|

• Supplies power to electric motor.

• Stores electrical power regenerated by electric motor.

|

|

BECM

|

• BECM monitors the following high voltage battery conditions.

• Detects insulation condition of high voltage circuit by electrical leakage detection device in BECM and inputs it to PCM.

|

|

Battery charge control module

|

• During normal charging, converts alternating current supplied from charge port to direct current for charging high voltage battery.

• During charging, communicates with charging system and transmits communication content to PCM via CAN communication.

|

|

Charge port-electrical supply unit

|

• Drives and performs illumination control of following parts installed to charge port.

• During rapid charging, measures charge port temperature using charge inlet temperature sensor, and transmits it to PCM via CAN communication.

|

|

Electronically controlled brake unit

|

• During braking, calculates regenerative braking force, and transmits regenerative braking request to PCM and controls hydraulic braking force.

• While TSC or DSC is operating, transmits request signal for braking force control to PCM.

|