|

a30zzn00000991

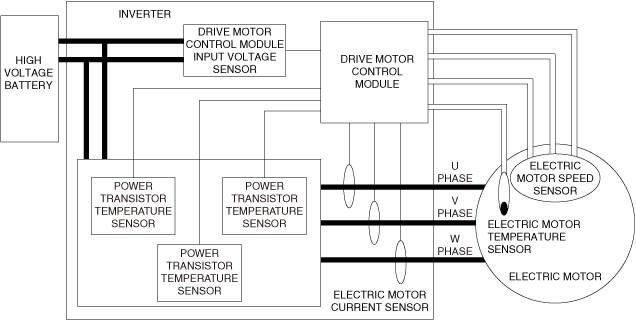

ELECTRIC DRIVE SYSTEM CONTROL

id301000200600

Drive Motor Control Module

Outline

a30zzn00000991

|

|

Part name |

Content |

|---|---|

|

Electric motor speed sensor

|

Detects the motor rotation angle and rotation direction. (See Electric Motor Speed Sensor.)

|

|

Electric motor temperature sensor

|

Detects the electric motor temperature and inputs signals which vary according to the electric motor temperature to the drive motor control module.

|

|

Electric motor current sensor

|

Detects electrical current in the U phase, V phase, and W phase in the electric motor and inputs the information to the drive motor control module.

|

|

Input voltage sensor

|

Detects the voltage to be input to the inverter from the high voltage battery and inputs the information to the drive motor control module.

|

|

Power transistor temperature sensor

|

Detects the power transistor temperatures at the U phase, V phase, and W phase in the inverter and inputs the information to the driver motor control module.

|

Construction

a30zzn00000992

|

System wiring diagram

a30zzn00001176

|

Electric Motor Speed Sensor

Purpose, Function

Construction

a30zzn00000994

|

Operation

a30zzn00000888

|

a30zzn00001164

|