|

a30zzn00002287

HIGH VOLTAGE BATTERY CONTROL SYSTEM

id304100101000

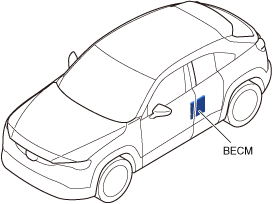

BECM

Outline

Functions

|

Function |

Content |

|---|---|

|

High voltage battery voltage detection

|

• Detects the voltage value of each high voltage battery cell (96 cells).

|

|

High voltage battery electrical current detection

|

• Detects the electrical current value of the high voltage battery.

|

|

High voltage battery temperature detection

|

• Detects the temperature of each high voltage battery module (16 modules).

|

|

High voltage battery electrical leakage detection

|

• Detects the insulation resistance of the high voltage battery voltage and electrical leakage.

|

|

Cell balancing control

|

• Equalizes the charge amount of each high voltage battery cell.

• If the fluctuation in the charge amount of the specified value or more occurs in cell voltage, cell balancing control is performed by the BECM.

• Monitors the state of charge of each cell and reduces the charge amount in cells with a high charge to equalize the charge amount.

|

|

SOC/SOH/SOF estimation

|

• Estimates SOC (charging capacity) / SOH (deterioration condition) / SOF (discharge performance).

|

|

Power supply voltage detection

|

• Monitors the power supply voltage input to the BECM.

|

|

On-board diagnostic function

|

• Communicates with each sensor input to the BECM, and performs malfunction diagnosis.

|

|

CAN communication function

|

• The high voltage battery condition is sent to each control module via CAN communication.

|

|

Battery heater contactor drive

|

• Turns the battery heater contactor on/off.

|

|

PCM operation

|

• Operates the PCM by supplying power to the PCM from the BECM.

|

|

QBC voltage detection

|

• Detects the charge voltage during quick charge.

|

|

Refrigerant temperature detection

|

• Detects the high voltage battery cooling refrigerant temperature.

|

|

Refrigerant pressure detection

|

• Detects the high voltage battery cooling refrigerant pressure.

|

|

Electric expansion valve drive

|

• Sends a drive signal to the electric expansion valve for cooling the high voltage battery, and drives the electric expansion valve.

|

Construction

a30zzn00002287

|

High voltage battery cell voltage sensor

Purpose, Function

Construction

High voltage battery module temperature sensor

Purpose, Function

Construction

High voltage battery current sensor

Purpose, Function

Construction

a30zzn00001019

|

Refrigerant pressure sensor No.2

Purpose, Function

Construction

am2zzn00002150

|

Operation

am2zzn00002151

|

a30jjn00000198

|

Temperature sensor of refrigerant line for the high voltage battery

Purpose, Function

Construction

Operation

aaxjjn00008113

|

QBC (Quick Battery Charge) Voltage Sensor

Purpose, Function

Construction

a30zzn00001020

|

CELL BANCING CONTROL

Outline

a30zzn00000955

|

Block Diagram

a30zzn00001117

|

Operation

a30zzn00000957

|