CHARGE CONNECTOR LOCK ACTUATOR INSPECTION

id304200000700

-

Warning

-

<<High voltage>>

• If the necessary measures are not taken before servicing an electric vehicle, it could cause electrical shock and result in serious injury or, in the worst case, death. Before servicing the electric vehicle, refer to [HIGH VOLTAGE SERVICE CAUTIONS] in the general information and implement the necessary measures. (See

HIGH VOLTAGE SERVICE CAUTIONS.)

High Voltage Part Inspection And Removal/Installation Notes

-

Warning

-

<<High voltage>>

• If necessary measures such as wearing the correct protective gear are not taken when inspecting or removing/installing the high voltage parts, it could cause electrical shock and result in serious injury or, in the worst case, death.

• Before inspecting or removing/installing the high voltage parts, refer to [HIGH VOLTAGE SERVICE CAUTIONS] in the general information and [High Voltage Part Inspection and Removal/Installation Notes] of the high voltage system service cautions and implement the necessary measures and preparations. (See

HIGH VOLTAGE SERVICE CAUTIONS.) (See

HIGH VOLTAGE SYSTEM SERVICE CAUTIONS.)

Visual inspection

1. Verify that the charge connector lock actuator is free of deformation, color change, distortion, and cracking, and that excessive grease is not adhering to the actuator.

-

• Wipe off excessive grease on the charge connector lock actuator.

Operation Inspection

1. Disconnect the negative lead-acid battery terminal. (See NEGATIVE LEAD-ACID BATTERY TERMINAL DISCONNECTION/CONNECTION.)

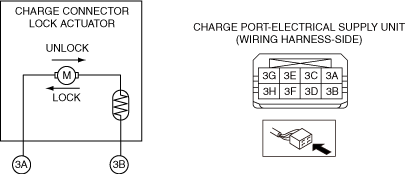

2. Disconnect the charge port-electrical supply unit connector.

3. Apply lead-acid battery voltage and connect the ground to each terminal of the charge port-electrical supply unit as indicated in the table below and verify that the charge connector lock actuator operates.

|

Terminal B+

|

Ground terminal

|

Operation

|

|

3A

|

3B

|

Unlock

|

|

3B

|

3A

|

Lock

|

-