MANUAL TRANSMISSION PARTS INSPECTION

D5E051100000M02

Clutch Hub Component

1. Measure the clearance between each shift fork and clutch hub sleeve groove using a feeler gauge.

-

• If not within the specification, replace the shift fork and clutch hub sleeve as a set.

Standard clearance between shift fork and clutch hub sleeve groove

-

0.05-0.40 mm {0.002-0.015 in}

Maximum clearance between shift fork and clutch hub sleeve groove

-

0.5 mm {0.020 in}

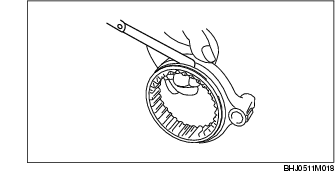

Synchronizer Ring

1. Measure the clearance between the synchronizer ring and flank surface of the gear using a feeler gauge around the entire circumference.

-

• If not within the specification, replace the synchronizer ring.

Standard clearance between synchronizer ring and flank surface of gear

-

1.5 mm {0.059 in}

Maximum clearance between synchronizer ring and flank surface of gear

-

0.8 mm {0.031 in}

-

Note

-

• Set the synchronizer ring squarely in the gear.

Spring

1. Measure the free length of each spring.

-

• If not within the specification, replace the spring.

Detent ball spring

-

Standard length: 23.5 mm {0.925 in}

1st/2nd select return spring

-

Standard length: 83.5 mm {3.287 in}

Mainshaft

1. Measure the mainshaft runout using a dial gauge.

-

• If it exceeds the maximum specification, replace the mainshaft.

Mainshaft maximum runout

-

0.03 mm {0.0012 in}

Shift Rod End, Control Lever

1. Measure the clearance between the shift rod end and control lever using a feeler gauge.

-

• If not within the specification, replace the shift rod end or control lever as a set.

Standard clearance between shift rod end and control lever

-

0.5 mm {0.020 in} or less