STEP

INSPECTION

ACTION

1

• Turn the ignition switch to the ON position.

• Is there any malfunction in the fuel gauge such as the needle not moving from the E mark, or the needle does not point to the F mark even if the fuel tank is full?

• Does the high engine coolant temperature warning light illuminate or flash from 3 to 30 s when the ignition is switched ON?

Yes

Troubleshooting completed.

No

Go to the next step.

2

• Start the instrument cluster input/output check mode.

• Select the check code 22.

• Display value is 7—206?

Yes

Go to the next step.

No

Go to Step 4.

3

• Perform the check code 23 inspection.

• Is there any malfunction?

Yes

Replace the instrument cluster.

No

Go to the next step.

4

• Perform the check code 22 inspection.

• Is there any malfunction?

Yes

Go to the next step.

No

Go to Step 6.

5

• Turn the ignition switch to LOCK position.

• Inspect the instrument cluster connector terminals for poor connection (such as damaged/pulled-out pins, and corrosion).

• Are the terminals normal?

Yes

Replace the instrument cluster.

No

Repair or replace the terminal.

6

• Turn the ignition switch to LOCK position.

• Remove the instrument cluster.

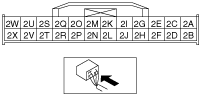

• Disconnect the instrument cluster connector.

• Inspect for continuity between the following wiring harnesses.

-

― 2R terminal—GND― 2T terminal—GND

• Is there continuity?

Yes

Repair or replace the wiring harness between the instrument cluster and GND.

No

Go to the next step.

7

• Turn the ignition switch to LOCK position.

• Inspect the fuel gauge sender unit connector terminals for poor connection (such as damaged/pulled-out pins, and corrosion).

• Are the terminals normal?

Yes

Go to the next step.

No

Repair or replace the terminal.

8

• Turn the ignition switch to LOCK position.

• Inspect for continuity following the wiring harness between instrument cluster and fuel gauge sender unit.

-

― 2R terminal—C terminal― 2T terminal—A terminal

• Is there continuity?

Yes

Go to the next step.

No

Repair or replace the wiring harness between the instrument cluster and the fuel gauge sender unit.

9

• Turn the ignition switch to LOCK position.

• Is the fuel gauge sender unit installed properly?

Yes

Inspect the fuel gauge sender unit.

No

Reinstall the fuel gauge sender unit.