|

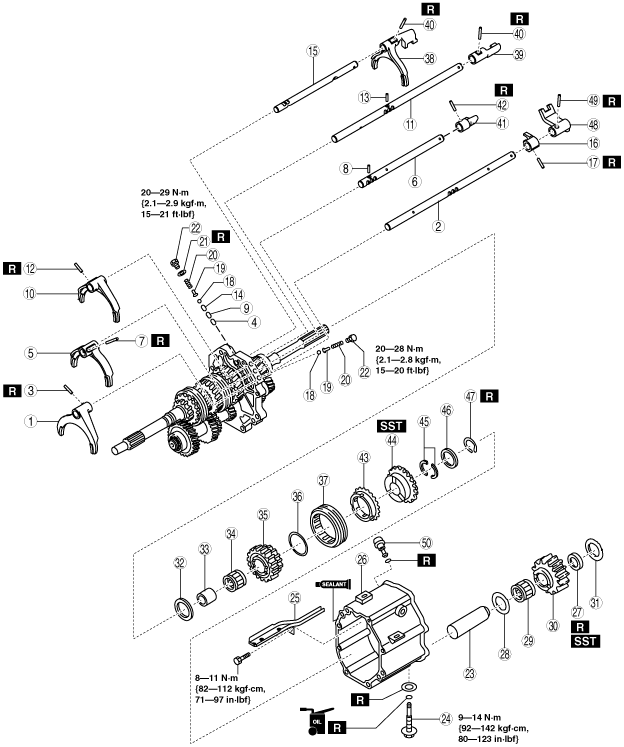

SHIFT FORK, SHIFT ROD AND REVERSE GEAR PARTS ASSEMBLY

id051100010500

1. Assemble in the order shown in the figure.

bmm8um00000047

|

|

1

|

5th/6th shift fork

|

|

2

|

5th/6th shift rod

(See Shift Rod Assembly Note.)

|

|

3

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

4

|

Interlock pin (short)

|

|

5

|

3rd/4th shift fork

|

|

6

|

3rd/4th shift rod

(See Shift Rod Assembly Note.)

|

|

7

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

8

|

Interlock pin (long)

|

|

9

|

Interlock pin (short)

|

|

10

|

1st/2nd shift fork

|

|

11

|

1st/2nd shift rod

(See Shift Rod Assembly Note.)

|

|

12

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

13

|

Interlock pin (long)

|

|

14

|

Interlock pin (short)

|

|

15

|

Reverse shift rod

(See Shift Rod Assembly Note.)

|

|

16

|

Stopper block

|

|

17

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

18

|

Detent ball

|

|

19

|

Spring seat

|

|

20

|

Spring

|

|

21

|

Washer

|

|

22

|

Cap plug

|

|

23

|

Reverse idle gear shaft

|

|

24

|

Idle shaft pin

(See Idle Shaft Pin Assembly Note.)

|

|

25

|

Oil guide

|

|

26

|

Intermediate housing

|

|

27

|

Friction damper

|

|

28

|

Washer

|

|

29

|

Bearing

|

|

30

|

Reverse idle gear

|

|

31

|

Washer

|

|

32

|

Washer

|

|

33

|

Bearing race

|

|

34

|

Bearing

|

|

35

|

Reverse gear

|

|

36

|

Reverse synchronizer key spring

|

|

37

|

Reverse clutch hub sleeve

|

|

38

|

Reverse shift fork

|

|

39

|

1st/2nd shift rod end

|

|

40

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

41

|

3rd/4th shift rod end

|

|

42

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

43

|

Reverse synchronizer ring

|

|

44

|

Reverse synchronizer cone

|

|

45

|

C-washer

(See C-washer Assembly Note.)

|

|

46

|

Washer

|

|

47

|

Snap ring

|

|

48

|

5th/6th shift rod end

|

|

49

|

Roll pin

(See Roll Pin Assembly Note.)

|

|

50

|

Breather

|

Shift Rod Assembly Note

1. Assemble the shift rods to the bearing housing with the shift rod grooves shown in the figure pointed towards the shift check mechanism side.

bmm7zm00000003

|

Roll Pin Assembly Note

1. Assemble the new roll pins using a pin punch and a hammer.

bmm8um00000012

|

|

Roll pin location of use |

Tap-in amount type |

|---|---|

|

5th/6th shift fork

|

Type A

|

|

1st/2nd shift fork

|

Type A

|

|

3rd/4th shift fork

|

Type A

|

|

Stopper block

|

Type A

|

|

1st/2nd shift rod end

|

Type B

|

|

3rd/4th shift rod end

|

Type B

|

|

5th/6th shift rod end

|

Type B

|

|

Reverse shift fork

|

Type B

|

Interlock Pin (Short)/(Long) Assembly Note

1. Assemble the interlock pins (short)/(long) to the positions on the bearing housing shown in the figure using a magnet.

bmm7zm00000004

|

Idle Shaft Pin Assembly Note

1. Assemble the new O-ring to the end of the idle shaft pin, and apply transmission oil (long-life gear oil IS).

bmm8um00000014

|

2. Assemble the idle shaft pin through the new washer.

Intermediate Housing Assembly Note

1. Apply silicone sealant TB1217E to the intermediate housing as shown in the figure.

bmm6jm00000058

|

2. Assemble the intermediate housing.

Friction Damper Assembly Note

1. Assemble the new friction damper to the reverse idle gear using the SST and the press.

bmm8um00000015

|

Reverse Clutch Hub Sleeve Assembly Note

1. Assemble so that the reverse clutch hub sleeve marking is pointing toward the extension housing side.

bmm8um00000016

|

Reverse Synchronizer Cone Assembly Note

1. Assemble the reverse synchronizer cone using the SSTs and a hammer.

bmm6jm00000061

|

C-washer Assembly Note

1. Assemble the removed C-washer during disassembly to the washer, and assemble the snap ring.

2. Measure the clearance between the reverse synchronizer cone and C-washer with a thickness gauge.

bmm8um00000017

|

|

C-washer thickness (mm {in}) |

|---|

|

3.1 {0.123}

|

|

3.2 {0.126}

|

|

3.3 {0.130}

|

|

3.4 {0.134}

|

3. Assemble the adjusted C-washer to the washer and assemble the new snap ring.