MAINSHAFT AND COUNTERSHAFT PARTS INSPECTION

id051100010700

Bearing Inspection

1. Inspect for damage and the rotation condition.

-

• If there is any malfunction, replace the bearing.

Each Gear, Main Drive Gear Inspection

1. Inspect the following. If there is any malfunction, replace the malfunctioning part.

-

• Inspect for wear of the synchronizer cone.

• Inspect the teeth of each gear for damage, wear, or loss.

• Inspect the connection part of the hub sleeve for wear or damage.

• Inspect the teeth of the synchronizer ring for damage, wear, or loss.

• Inspect the main drive gear spline for damage, wear, or loss.

Shift Fork (3rd/4th) Inspection

1. Using a thickness gauge, measure the clearance between each shift fork and the clutch hub sleeve groove.

-

Clearance between clutch hub sleeve and shift fork

-

Standard: 0.2—0.3 mm {0.008—0.011 in}

Maximum: 0.5 mm {0.02 in}

-

• If it exceeds the maximum specification, replace the shift fork and clutch hub sleeve.

Clutch Hub Component (3rd/4th) Inspection

1. Inspect the following. If there is any malfunction, replace the clutch hub component.

-

• Inspect the list of operations when the clutch hub sleeve is installed to the hub.

• Inspect the teeth of each gear for damage, wear, or loss.

• Inspect the synchronizer key groove for wear or loss.

Synchronizer ring (3rd/4th/6th) Inspection

1. Inspect the following. If there is any malfunction, replace the synchronizer ring.

-

• Inspect the teeth of the synchronizer ring for damage, wear, or loss.

• Inspect the taper surface for wear or loss.

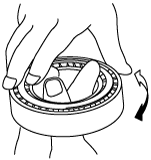

2. Measure the clearance of the synchronizer ring and gear side surface around the entire circumference using a thickness gauge.

-

Clearance of synchronizer ring (3rd/4th/6th) and gear side surface

-

Standard: 1.5 mm {0.059 in}

Maximum: 0.8 mm {0.031 in}

-

• If it exceeds the maximum specification, replace the synchronizer ring.

Countershaft Inspection

1. Inspect the following. If there is any malfunction, replace the countershaft.

-

• Inspect the teeth of each gear for damage, wear, or loss.

• Inspect the spline for damage, wear, or loss.