MAINSHAFT PARTS INSPECTION

id051100011000

Each Gear Inspection

1. Inspect the following. If there is any malfunction, replace the malfunctioning part.

-

• Inspect the synchronizer cone for wear.

• Inspect the teeth of each gear for damage, wear, or loss.

• Inspect the hub sleeve connecting part for wear or damage.

• Inspect the teeth of the synchronizer ring for damage, wear, or loss.

Clutch Hub Component Inspection

1. Inspect the following. If there is any malfunction, replace the clutch hub component.

-

• Inspect the list of operations when installing the clutch hub sleeve to the hub.

• Inspect the teeth of each gear for damage, wear, or loss.

• Inspect the synchronizer key groove for wear or loss.

Shift Fork (1st/2nd, 5th/6th) Inspection

1. Using a thickness gauge, measure the clearance between each shift fork and the clutch hub sleeve groove.

-

Clearance between clutch hub sleeve and shift fork

-

Standard: 0.2—0.3 mm {0.008—0.011 in}

Maximum: 0.5 mm {0.02 in}

-

• If it exceeds the maximum specification, replace the shift fork and the clutch hub sleeve.

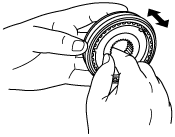

Synchronizer Ring (1st, 2nd, 5th) Inspection

1. Inspect the following. If there is any malfunction, replace the synchronizer ring.

-

• Inspect the teeth of the synchronizer ring for damage, wear, or loss.

• Inspect the taper surface for wear or loss.

2. Using a thickness gauge, measure the clearance of the synchronizer ring and gear side surface around the entire circumference.

-

Clearance of synchronizer ring (1st, 2nd, 5th) and gear side surface

-

Standard: 1.5 mm {0.059 in}

Maximum: 0.8 mm {0.031 in}

-

• If it exceeds the maximum specification, replace the synchronizer ring.

Main Shaft Inspection

1. Measure the main shaft runout using a dial gauge.

-

Runout of main shaft

-

Maximum: 0.03 mm {0.0012 in}

-

• If it exceeds the maximum specification, replace the main shaft.

2. Inspect the spline for damage and wear.

3. Inspect the main shaft connecting part for wear or damage.

4. Measure the clearance between the main shaft and gear (or bearing race).

-

Clearance between main shaft and gear (or bearing race)

-

Maximum: 0.15 mm {0.0059 in}

-

• If it exceeds the maximum specification, replace the main shaft.