|

1

|

RECORD VEHICLE STATUS WHEN DTC WAS DETECTED TO UTILIZE WITH REPEATABILITY VERIFICATION

-

Note

-

• Recording can be facilitated using the screen capture function of the PC.

• Record the freeze frame data/snap shot data.

|

—

|

Go to the next step.

|

|

2

|

VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT FUSE CONDITION

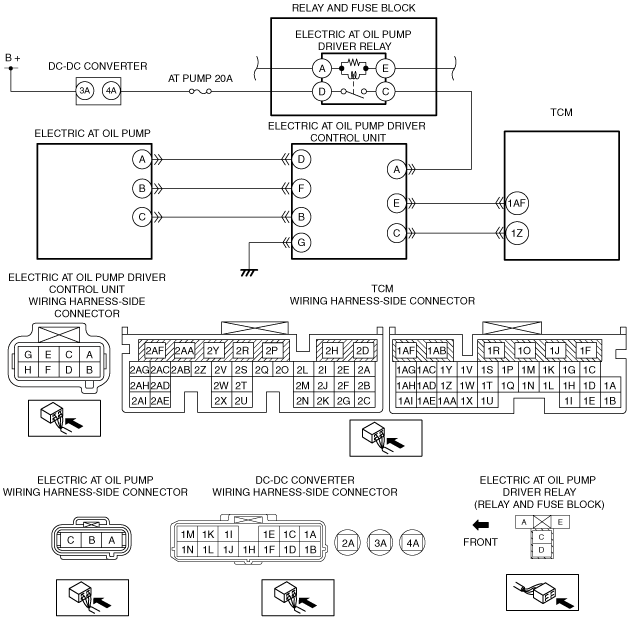

• Is the fuse (AT PUMP 20A) normal?

|

Yes

|

Go to the next step.

|

|

No

|

• If the fuse is blown:

-

― Refer to the wiring diagram and verify if there is a common connector between fuse and electric AT oil pump driver control unit terminal A.

If there is a common connector:

-

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

-

• Repair or replace the wiring harness which is shorted to ground.

• Replace the fuse.

• If the fuse is damaged:

-

― Replace the fuse.

Go to Step 16.

|

|

4

|

INSPECT TCM CONNECTOR

• Switch the ignition off.

• Disconnect the TCM connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is there any malfunctioning location?

|

Yes

|

Repair or replace the connector/terminal, then go to Step 16.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT POWER SUPPLY FOR OPEN CIRCUIT

• Disconnect the electric AT oil pump driver control unit connector.

• Switch the ignition ON (engine off).

• Measure the voltage between electric AT oil pump driver control unit terminal A (vehicle wiring harness side) and electric AT oil pump driver control unit terminal G (vehicle wiring harness side).

• Is the voltage between 9–16 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Battery and DC-DC converter terminal 3A

• DC-DC converter terminal 4A and electric AT oil pump driver control unit terminal A

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 16.

|

|

6

|

INSPECT FOR SHORT TO GROUND IN ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT POWER SUPPLY CIRCUIT

• Switch the ignition off.

• Inspect for continuity between electric AT oil pump driver control unit terminal A (vehicle wiring harness side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Battery and DC-DC converter terminal 3A

• DC-DC converter terminal 4A and electric AT oil pump driver control unit terminal A

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to ground.

Go to Step 16.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT FOR SHORT TO GROUND IN ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT CIRCUIT

• Disconnect the TCM connector.

• Inspect for continuity between the following terminals (vehicle wiring harness side) and body ground.

-

― TCM terminal 1AF

― TCM terminal 1Z

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• TCM terminal 1AF and electric AT oil pump driver control unit terminal E

• TCM terminal 1Z and electric AT oil pump driver control unit terminal C

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to ground.

Go to Step 16.

|

|

No

|

Go to the next step.

|

|

8

|

INSPECT FOR SHORT TO POWER SUPPLY IN ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT CIRCUIT

• Connect the TCM connector.

• Start the engine.

• Measure the voltage between the following terminals (vehicle wiring harness side) and body ground before/after operating i-stop.

-

― TCM terminal 1AF

― TCM terminal 1Z

• Is the voltage B+ constantly?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• TCM terminal 1AF and electric AT oil pump driver control unit terminal E

• TCM terminal 1Z and electric AT oil pump driver control unit terminal C

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to power supply to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to the power supply.

Go to Step 16.

|

|

No

|

Go to the next step.

|

|

9

|

INSPECT ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT CONNECTOR

• Switch the ignition off.

• Disconnect the electric AT oil pump driver control unit connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is there any malfunctioning location?

|

Yes

|

Repair or replace the connector/terminal, then go to Step 16.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT FOR OPEN CIRCUIT

• Disconnect the TCM connector.

• Disconnect the electric AT oil pump driver control unit connector.

• Inspect the wiring harness for continuity between the following terminals (vehicle wiring harness side).

-

― TCM terminal 1AF and electric AT oil pump driver control unit terminal E

― TCM terminal 1Z and electric AT oil pump driver control unit terminal C

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• TCM terminal 1AF and electric AT oil pump driver control unit terminal E

• TCM terminal 1Z and electric AT oil pump driver control unit terminal C

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 16.

|

|

11

|

INSPECT ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT GROUND CIRCUIT FOR OPEN CIRCUIT

• Verify that the selector lever component connector is disconnected.

• Inspect for continuity between electric AT oil pump driver control unit terminal G (vehicle wiring harness side) and body ground.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between electric AT oil pump driver control unit terminal G and body ground.

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 16.

|

|

12

|

INSPECT ELECTRIC AT OIL PUMP CONNECTOR

• Switch the ignition off.

• Disconnect the electric AT oil pump connector.

• Inspect the connector engagement and connection condition, and inspect the terminals for damage, deformation, corrosion, or disconnection.

• Is there any malfunctioning location?

|

Yes

|

Repair or replace the connector/terminal, then go to Step 16.

|

|

No

|

Go to the next step.

|

|

13

|

INSPECT FOR SHORT TO GROUND IN ELECTRIC AT OIL PUMP CIRCUIT

• Disconnect the TCM connector.

• Inspect for continuity between the following terminals (vehicle wiring harness side) and body ground.

-

― Electric AT oil pump terminal A

― Electric AT oil pump terminal B

― Electric AT oil pump terminal C

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Electric AT oil pump terminal A and electric AT oil pump driver control unit terminal D

• Electric AT oil pump terminal B and electric AT oil pump driver control unit terminal F

• Electric AT oil pump terminal C and electric AT oil pump driver control unit terminal B

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to ground to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to ground.

Go to Step 16.

|

|

No

|

Go to the next step.

|

|

14

|

INSPECT FOR SHORT TO POWER SUPPLY IN ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT CIRCUIT

• Connect the TCM connector.

• Start the engine.

• Measure the voltage between the following terminals (vehicle wiring harness side) and body ground before/after operating i-stop.

-

― Electric AT oil pump terminal A

― Electric AT oil pump terminal B

― Electric AT oil pump terminal C

• Is the voltage B+ constantly?

|

Yes

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Electric AT oil pump terminal A and electric AT oil pump driver control unit terminal D

• Electric AT oil pump terminal B and electric AT oil pump driver control unit terminal F

• Electric AT oil pump terminal C and electric AT oil pump driver control unit terminal B

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for short to power supply to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which is shorted to the power supply.

Go to Step 16.

|

|

No

|

Go to the next step.

|

|

15

|

INSPECT ELECTRIC AT OIL PUMP DRIVER CONTROL UNIT FOR OPEN CIRCUIT

• Disconnect the TCM connector.

• Disconnect the electric AT oil pump driver control unit connector.

• Inspect the wiring harness for continuity between the following terminals (vehicle wiring harness side).

-

― Electric AT oil pump terminal A and electric AT oil pump driver control unit terminal D

― Electric AT oil pump terminal B and electric AT oil pump driver control unit terminal F

― Electric AT oil pump terminal C and electric AT oil pump driver control unit terminal B

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify if there is a common connector between the following terminals.

• Electric AT oil pump terminal A and electric AT oil pump driver control unit terminal D

• Electric AT oil pump terminal B and electric AT oil pump driver control unit terminal F

• Electric AT oil pump terminal C and electric AT oil pump driver control unit terminal B

If there is a common connector:

• Inspect the common connector and terminals for corrosion, damage, or disconnection and the common wiring harnesses for an open circuit to determine the malfunctioning location.

• Repair or replace the malfunctioning location.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to the next step.

|

|

16

|

VERIFY SAME DTC IS NOT PRESENT

• Clear DTC for the TCM using the M-MDS.

• Perform the DTC inspection for the TCM using the M-MDS.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

|

|

No

|

Go to the next step.

|

|

17

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Clear the DTC using the M-MDS.

• Perform the DTC inspection using the M-MDS.

• Are any DTCs present?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|