|

OIL COOLER FLUSHING [SJ6A-EL]

id051311710900

1. Remove the two oil cooler line hoses and apply air pressure of 196 kPa {2.0 kgf/cm2, 28 psi} from the return hose (pipe) side.

amxzzw00004478

|

2. If no air blows out of the feed side, flush the oil cooler lines using the power-flushing tool. (See Power Flushing.)

Recommended power-flushing manufacturer

|

Manufacturer |

Part number |

Description |

|---|---|---|

|

Kent Moore

|

J35944-AMAZ

|

Flushing kit or equivalent

|

|

OTC

|

60081

|

Portable torque converter, oil cooler cleaner or equivalent

|

Power Flushing

Repair procedure

1. Before power flushing, inspect the hoses/lines and clamps. Power flushing must begin with back flushing followed by forward flushing to quickly dislodge the restriction. If back flushing is not performed before forward flushing, the restriction could further reduce the ATF flow through the internal mesh type baffle of the cooler and flushing will not be effective or possible.

Inspecting oil lines and clamps

1. Always inspect the lines (hoses/pipes) for cuts, crimps (pinched), cracks or any other damage before reusing them.

Back flushing

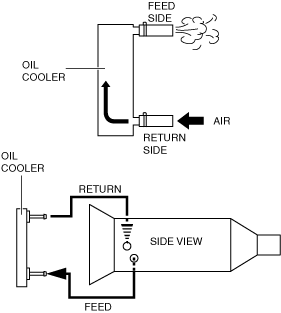

1. Following the power flushing equipment manufacturer’s instructions, connect equipment so the flushing fluid flows in the opposite direction of normal fluid flow.

amxuuw00003571

|

2. Flush oil cooler/lines until discharge fluid is clean.

Forward flushing

1. Connect power flushing equipment so the flushing fluid flows in the direction of normal fluid flow.

amxuuw00003572

|

2. Flush oil cooler/lines until discharged fluid is clean.