ALUMINUM REPAIR WORK CAUTION

id000000740000

• If aluminum sheet metal is repaired the same way as steel sheet metal, the following events may occur.

|

Safety area

|

Dust explosion

|

|

Quality area

|

Corrosion caused by cross-metal contamination

|

|

Cracks (deep scratches included)

|

|

Stretching

|

|

Strength degradation from excessive grinding

|

|

Poor adhesion, rust

|

• Plant and workers are to abide by the following cautions to prevent these events from occurring.

Dust Explosion

• If the concentration of aluminum dust suspended in the air while grinding aluminum material using a grinder or sander reaches a concentration of 30 g/m3 or more, and an oxygen and an ignition source (sparks occurring from welding spatter or static electricity from work clothing) are applied, it could cause a dust explosion. In a sheet metal and paint workshop, the greatest danger of a dust explosion occurring is when cleaning/replacing the dust collector filter which contains large amounts of aluminum dust.

-

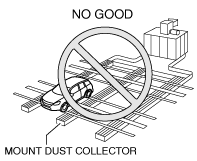

― Do not use the mounted dust collector when grinding aluminum, because aluminum dust which is collected may scatter and become suspended in the air during dust collector filter maintenance or replacement.

― For aluminum grinding work, prepare an explosion-proof dust collector with which static electricity during dust suctioning can be prevented, and aluminum dust is collected in a paper bag and the bag can be disposed of during maintenance. Do not use a grinder equipped with a dust collector bag, because the aluminum dust may scatter when cleaning the dust collector bag.

Corrosion Caused by Cross-Metal Contamination

• If cross-contamination with a different type of metal dust occurs, it could corrode the aluminum.

-

― Set up a work booth exclusive for aluminum. Separate the general work booth area with a partition such as a slide-type curtain when using a general work booth for aluminum repair work, and always clean and remove any iron dust before starting aluminum repair work.

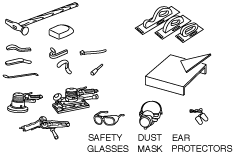

― Prepare machinery and protective equipment exclusive for aluminum when performing aluminum repair work. Always clean and remove any iron dust from the surface of the machinery and protective equipment used for steel sheet metal when using them for aluminum repair work.

― When using a stud welder for aluminum repair work, prepare a stud welder for aluminum and a stud pin exclusive for aluminum.

― Prepare polishing materials for the new panel, work gloves and sandpaper for putty and coat grinding work, and cloth for degreasing work exclusive for aluminum.

― Store machinery and protective equipment exclusive for aluminum in an exclusive tool box and set it in the work booth exclusive for aluminum, to prevent iron dust from adhering to them.

― If the points where the outer aluminum panel is installed are ground with excessive force, the anti-corrosive surface finishing for corrosion caused by cross-metal contamination may be ground off.

― Use exclusive surface finished bolts for the aluminum panel installation bolts.

Cracks (Deep Scratches Included)

• If hammering or pulling work is performed with excessive force without the application of heat, cracks in the aluminum panel may occur. In addition, if a texture hammer or a slapping file is used, it could cause deep scratches and subsequent cracking of the aluminum panel.

-

― Always thoroughly polish the contact points of the hammer and dolly to prevent scratches to the aluminum panel.

― When hammering or using a stud welder for aluminum repair work, perform heat repairs while warming the metal with a gas burner.

― In addition, keep the temperature at around 200°C {392 °F} during heat repair work using a non-contact thermometer, thermal crayons or thermal stickers. When using a non-contact thermometer, measure the painted surface because the aluminum surface cannot be measured accurately.

― When grinding aluminum, use sandpaper which is finer than the sandpaper used for sheet metal repair work. Newly replace the sandpaper as soon as it becomes clogged.

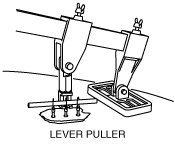

― Use a lever puller when performing pulling work using the stud welder.

― Perform a liquid penetrant test when inspecting cracks.

― Do not use texture hammers and flexible files when performing aluminum repair work.

Stretching

• Aluminum sheet metal may stretch more compared to steel sheet metal due to the heat occurring from high-speed grinding or frequent use of on-dolly hammering.

-

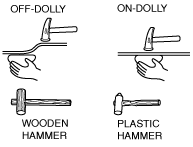

― When hammering, perform mostly off-dolly hammering, and when performing on-dolly hammering, lightly tap the hammer. Rubber hammers, wooden hammers and plastic hammers can also be used.

― When grinding aluminum with a grinder, avoid high speed grinding as much as possible to prevent grinding heat from occurring.

Strength Degradation from Excessive Grinding

• Because aluminum sheet metal is softer than steel sheet metal, if the same type of grindstone or course textured sandpaper for steel sheet metal is used when sanding off the paint coat, the strength of the aluminum sheet metal could be reduced due to excessive grinding.

-

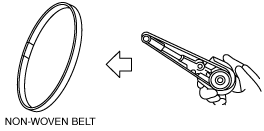

― Use a non-woven fabric grinder (such as a non-woven belt) instead of a grinding stone grinder for the paint coating and aluminum grinding, because aluminum sheet metal is softer than steel sheet metal.

― Use a soft interface disc pad with the double action sander to reduce pressing force when grinding aluminum.

― When using a pneumatic tool such as a grinder, reduce its speed to a lower speed than that which is set for steel sheet metal, because aluminum sheet metal is softer than steel sheet metal.

Poor Adhesion, Rust

• If a genuine primer is not applied to the areas where the aluminum is exposed, poor adhesion or rust may occur.

-

― Coat the aluminum areas which were exposed during the repair process with genuine primer. When applying the genuine primer, use the products specified by each paint manufacturer, and perform the procedure always following the instructions of each paint manufacturer's instruction manual.