|

e5u140zw5503

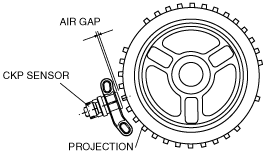

CRANKSHAFT POSITION (CKP) SENSOR INSPECTION [L8, LF]

id0140i7800500

Air Gap Inspection

1. Verify that the CKP sensor is securely installed.

2. Using a thickness gauge, measure the air gap between the plate projections at the back of crankshaft pulley and the CKP sensor.

e5u140zw5503

|

Visual inspection

1. Remove the battery cover. (See BATTERY REMOVAL/INSTALLATION [L8, LF].)

2. Disconnect the negative battery cable. (See BATTERY REMOVAL/INSTALLATION [L8, LF].)

3. Remove the CKP sensor. (See CRANKSHAFT POSITION (CKP) SENSOR REMOVAL/INSTALLATION [L8, LF].)

4. Verify that there are no metal shavings on the sensor.

Voltage Inspection

1. Idle the engine.

2. Measure the CKP sensor output wave pattern using an oscilloscope. (See PCM INSPECTION [L8, LF].)