|

acxaaw00000732

CLUTCH COVER INSPECTION [F35M-R]

id051005800800

1. Refer to CLUTCH UNIT REMOVAL/INSTALLATION to remove the clutch cover. (See CLUTCH UNIT REMOVAL/INSTALLATION [F35M-R].)

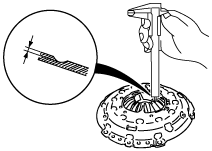

2. Measure the wear of the diaphragm spring fingers.

acxaaw00000732

|

3. Measure the flatness of the pressure plate with a straight edge and a feeler gauge.

acxaaw00000733

|

4. When checking the diaphragm spring fingers, mount a dial indicator on the cylinder block.

5. Rotate the flywheel and check for misaligned diaphragm spring fingers.

adejjw00001003

|

6. Install in the reverse order of removal.

7. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [F35M-R].)