|

am2zzw00004779

CLUTCH DISC INSPECTION [F35M-R]

id051005800900

1. Refer to CLUTCH UNIT REMOVAL/INSTALLATION to remove the clutch disc. (See CLUTCH UNIT REMOVAL/INSTALLATION [F35M-R].)

2. Inspect the lining surface for discoloration and grease adhesion.

3. Inspect the torsion spring for weakness and the rivet for looseness.

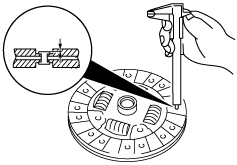

4. Using a vernier caliper, measure the depth between the lining surface and the rivet head.

am2zzw00004779

|

5. Measure the clutch disc runout using a dial gauge.

am2zzw00005136

|

6. Install in the reverse order of removal.

7. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [F35M-R].)