OIL SEAL (PARKING SHIFT LEVER) REPLACEMENT

id051700660500

-

Note

-

• Perform the following servicing only if the oil seal is replaced due to ATF leakage from the oil seal (parking shift lever).

1. Clean the outside of the transaxle. (See AUTOMATIC TRANSAXLE CLEANING.)

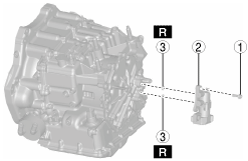

2. Remove the electric AT oil pump using the following procedure: (only vehicles with i-stop)

-

Caution

-

• Do not drop or apply a shock to the electric AT oil pump. Replace the electric AT oil pump with a new one if it was dropped or received an impact.

• Do not disassemble the electric AT oil pump. Replace the electric AT oil pump if it has been disassembled.

• Verify that there is no sealant or foreign matter in the electrical AT oil pump and transaxle. Otherwise, it could cause a malfunction.

• Be careful not to scratch or damage the aligning surfaces of the electric AT oil pump and end cover and the O-ring installation area so as not to cause ATF leakage.

|

1

|

3 bolts

|

|

2

|

Electric AT oil pump

|

|

3

|

O-ring

|

- (1) Remove the bolts shown in the figure.

-

- (2) Remove the electric AT oil pump.

-

-

Note

-

• Shake the electric AT oil pump by hand as shown in the figure and remove it.

- (3) Remove the O-rings.

-

3. Remove the stud bolts.

4. Remove the torque converter.

5. Install the transaxle to the SST (engine stand) using the following procedure:

-

Caution

-

• When installing the transaxle to the SST (engine stand) using chain hoists, be careful not to allow the transaxle (oil cooler in particular) to contact the SST (engine stand). If the transaxle contacts the SST, verify the areas which are contacted and replace damaged parts with new ones.

- (1) Install the SSTs to the transaxle using the following procedure.

-

-

Note

-

• When installing the SST (49 L010 1A0) to the transaxle (stud bolt holes), use new part number: 9YA02 1440 or M14 x 1.5 bolt, length 100 mm {3.94 in}.

• When installing the SST (49 UN30 3050) to the transaxle, use new part number: 9YA02 1015, or M10 x 1.5 bolts (length 35 mm {1.4 in}).

- 1) Temporarily install the arms (49 L010 102) using new part number: 9YA02 1440, or M14 x 1.5 bolts, length 100 mm {3.94 in}

-

-

Note

-

• To adjust the installation position of the SST in Step 3), temporarily tighten the bolts.

A :Part number: 9YA02 1440, or M14 x 1.5 bolt, length 100 mm {3.94 in}

- 2) Assemble the SST (49 L010 1A0).

-

-

Note

-

• Use bolts (49 L010 105) with a length of 138 mm {5.43 in}.

A :Washer

B :Approx. 20 mm {0.79 in}

C :Approx. 18 mm {0.71 in}

D :Approx. 47 mm {1.9 in}

- 3) Install the SST assembled in Step 2).

-

-

Note

-

• Adjust so that the plate (49 L010 101) and arms (49 L010 102) are level, and install.

A :Washer

B :Level out

- 4) Verify that nothing other than the SST arms (49 L010 102) installation area contacts the transaxle.

-

-

Caution

-

• If something other than the SST arms (49 L010 102) installation area contacts the transaxle, readjust the SST to prevent damaging the part.

- 5) Tighten the nuts and bolts.

-

-

Tightening torque

-

• Bolt: Part number: 9YA02 1440, or M14 x 1.5 bolt, length 100 mm {3.94 in}

40—52 N·m {4.1—5.3 kgf·m, 30—38 ft·lbf}

• Nut: 49 L010 104

140—160 N·m {15—16 kgf·m, 104—118 ft·lbf}

- 6) Assemble the SSTs using part number: 9YA02 1015, or M10 x 1.5 bolt (length 35 mm {1.4 in}).

-

A :Part number: 9YA02 1015, or M10 x 1.5 bolt, length 35 mm {1.4 in}

-

Tightening torque

-

38—52 N·m {3.9—5.3 kgf·m, 29—38 ft·lbf}

- (2) Using chain hoists, install the transaxle to the SST (engine stand) using part number: 9YA02 A220, or M12 x 1.75 bolt, length 40 mm {1.6 in}.

-

-

Caution

-

• When installing the transaxle to the SST (engine stand) using chain hoists, be careful not to allow the transaxle (oil cooler in particular) to contact the SST (engine stand). If the transaxle contacts the SST, verify the areas which are contacted and replace damaged parts with new ones.

-

Note

-

• Tighten the four locations with bolts and securely install the transaxle to the SST (engine stand).

A :Part number: 9YA02 A220, or M12 x 1.75 bolt, length 40 mm {1.6 in}

-

Tightening torque

-

88—118 N·m {9.0—12 kgf·m, 65—87 ft·lbf}

- (3) Remove the SSTs.

-

A :Part number: 9YA02 1015, or M10 x 1.5 bolt, length 35 mm {1.4 in}

6. Remove the converter housing using the following procedure:

|

1

|

21 bolts

|

|

2

|

Converter housing

|

|

3

|

O-ring (oil pump)

|

|

4

|

O-ring

|

- (1) Remove the bolts shown in the figure.

-

-

Caution

-

• Sealant has been applied to the removed bolts. If the bolts are reused it could cause ATF leakage, therefore when performing assembly use new bolts.

- (2) Remove the bolts shown in the figure.

-

- (3) Lightly tap the converter housing using a plastic hammer to remove it.

-

- (4) Remove the O-rings.

-

7. Remove the oil pump using the following procedure:

- (1) Remove the bolts shown in the figure.

-

- (2) Remove the oil pump.

-

8. Remove the thrust washer.

9. Remove the clutch component.

10. Remove the D-rings from the clutch component.

11. Remove the seal ring from the clutch component.

-

Caution

-

• Only remove the seal ring when replacing it.

• Do not damage the shaft part of the clutch component.

• Collect all fragments if the seal ring is damaged.

-

Note

-

• Remove the seal ring using a precision driver (flathead).

12. Remove the thrust needle bearing.

13. Remove the high clutch hub.

14. Remove the thrust needle bearing.

15. Remove the low clutch hub.

16. Remove the thrust needle bearing.

17. Remove the ring gear and differential.

18. Remove the thrust needle bearing.

19. Remove the oil pipe.

20. Remove the secondary gear and output gear.

21. Remove the thrust needle bearing.

22. Remove the roll pin using the following procedure:

- (1) Verify that the parking shift lever component is in the P position.

-

-

Caution

-

• If the parking shift lever component is in a position other than P, shift the parking shift lever component to the P position as shown in the figure.

A :Parking shift lever component

B :Manual plate component

C :Detent bracket component

- (2) Remove the roll pin shown in the figure using a pin punch.

-

-

Note

-

• Use a pin punch with an end outer diameter of 3 mm {0.119 in} or more and less than 4 mm {0.157 in}.

23. Remove the parking shift lever component.

24. Remove the oil seal.

-

Caution

-

• If the washer comes off together when the oil seal is removed, clean the washer and assemble it.

A: Washer

25. Assemble a new oil seal using the following procedure:

-

Caution

-

• If an oil seal is reused it could cause ATF leakage, therefore use a new oil seal.

- (1) Apply ATF (ATF FZ) to the engagement area of the new oil seal and transaxle case.

- (2) Apply ATF (ATF FZ) to the lip of the new oil seal.

- (3) Assemble the new oil seal to the position shown in the figure using the SST.

-

A :-0.3—0.3 mm {-0.01—0.01 in}

26. Assemble the parking shift lever component.

-

Note

-

• Pass the end of the parking shift lever component through the assembly hole (radial needle bearing) of the transaxle case, and assemble it to the manual plate component.

27. Assemble new roll pins using the following procedure:

- (1) Set the manual plate component and parking shift lever component as shown in the figure and align with the roll pin hole.

-

A :Roll pin hole

B :Manual plate component

C :Parking shift lever component

D :Detent bracket component

- (2) Assemble a new roll pin to the position shown in the figure using a pin punch.

-

-

Note

-

• Use a pin punch with an end outer diameter of 5 mm {0.2 in} or more.

A :0.00—1 mm {0.00—0.03 in}

28. Assemble the thrust needle bearing.

-

Note

-

• Thrust needle bearing size: Outer diameter approx. 67 mm {2.6 in}

29. Assemble the secondary gear and output gear.

30. Assemble the oil pipe.

-

Caution

-

• Do not assemble the oil pipe using a tool such as a hammer so as to prevent damaging the new part. For the oil pipe assembly, it is better to only use your hands to put the oil pipe into the output gear.

31. Assemble the thrust needle bearing.

-

Note

-

• Thrust needle bearing size: Outer diameter approx. 39.4 mm {1.55 in}

32. Assemble the ring gear and differential.

33. Assemble the thrust needle bearing.

-

Note

-

• Thrust needle bearing size: Inner diameter approx. 51.5 mm {2.03 in}

34. Assemble new seal rings to the clutch component using the following procedure:

-

Caution

-

• If a seal ring is reused it could cause ATF leakage, therefore use a new seal ring.

|

1

|

Seal ring (end cover side) (outer diameter approx. 24.6 mm {0.969 in}, thickness approx. 1.5 mm {0.059 in})

|

|

2

|

Seal ring (center section) (outer diameter approx. 24.6 mm {0.969 in}, thickness approx. 1.5 mm {0.059 in})

|

|

3

|

Seal ring (torque converter side) (outer diameter approx. 24.6 mm {0.969 in}, thickness approx. 1.5 mm {0.059 in})

|

- (1) Apply ATF (ATF FZ) to the new seal rings.

- (2) Roll an A4-size piece of paper onto the maximum diameter of the shaft.

-

-

Note

-

• Rolled piece of paper inner diameter approx. 27 mm {1.1 in}

- (3) Secure both ends of the rolled piece of paper with tape as shown in the figure.

-

A :TAPE

- (4) Align the rolled piece of paper with the seal ring groove of the clutch component.

-

-

Note

-

• The figure shows the seal ring groove (end cover side) lined up.

A :Rolled piece of paper

B :Seal ring (end cover side) installation position

- (5) Bend the rolled piece of paper to the end of the shaft.

-

- (6) Attach the new seal ring to the position approx. 5 mm {0.2 in} from the insertion side of the end of the rolled piece of paper, and align the seal ring end gap to the position of the tape.

-

-

Caution

-

• Be careful not to open the seal ring too much, it might become damaged.

A :Seal ring

- (7) Assemble the seal ring in the groove by pushing the seal ring evenly with a precision driver (Phillips).

-

-

Caution

-

• Because an operation malfunction might occur, verify that the seal ring is assembled to the groove.

- (8) Assemble the seal ring (center section) using the same procedure from Steps 1 to 7.

- (9) Assemble the seal ring (torque converter side) to the groove while using a finger to widen the seal ring.

-

-

Caution

-

• Be careful not to open the seal ring too much, it might become damaged.

35. Assemble new D-rings to the clutch component using the following procedure:

-

Caution

-

• If a D-ring is reused it could cause ATF leakage, therefore use a new D-ring.

- (1) Apply ATF (ATF FZ) to the new D-rings.

- (2) Assemble the new D-rings to the clutch component.

-

-

Note

-

• D-ring size: Outer diameter approx. 16.3 mm {0.642 in}, thickness approx. 1.6 mm {0.063 in}

36. Assemble together the clutch component, high clutch hub, low clutch hub, and thrust needle bearing using the following procedure:

- (1) Assemble the parts using the procedure shown in the figure:

-

|

1

|

Clutch component

|

|

2

|

Thrust needle bearing (outer diameter approx. 32.6 mm {1.28 in})

|

|

3

|

High clutch hub

|

|

4

|

Thrust needle bearing (outer diameter approx. 44 mm {1.7 in})

|

|

5

|

Low clutch hub

|

-

Note

-

• For the high clutch hub and low clutch hub assembly, assembly is easier if the work is performed using the following procedure:

-

― High clutch hub

-

1. Place the assembled parts on the workbench with the clutch component situated sideways.

2. While rotating the high clutch hub, engage the splines of each of the high clutch drive plates one by one, and assemble.

― Low clutch hub

-

1. Place the assembled parts on the workbench with the clutch component situated sideways.

2. While rotating the low clutch hub, engage the splines of each of the low clutch drive plates one by one, and assemble.

- (2) To verify that the parts are securely assembled together, measure the distance shown in the figure.

-

-

Note

-

• Recommended measuring instrument: Vernier caliper

-

Specification

-

60.60—62.09 mm {2.386—2.444 in}

-

• If not within the specification, disassemble the assembled parts and reassemble.

37. Assemble the parts which were assembled together in Step 36 using the following procedure:

- (1) Assemble the parts assembled together in Step 36.

-

- (2) To verify that the parts are securely assembled, measure the distance shown in the figure.

-

-

Note

-

• Recommended measuring instrument: Depth gauge, straight edge ruler

A :Transaxle case end (alignment surface with converter housing)

B :Clutch component end

-

Specification

-

8.46—9.88 mm {0.334—0.388 in}

-

• If not within the specification, remove the parts and perform re-assembly from Step 36.

-

Note

-

- 1) Set two straight edge rulers along the alignment surface of the transaxle case with the converter housing as shown in the figure.

- 2) Measure the positions (2 locations) shown in the figure using a depth gauge and calculate the average value.

-

A :Straight edge rulers

- 3) Subtract the thickness of the straight edge rulers from the average value.

38. Assemble the thrust washer.

-

Note

-

• Thrust washer size: Inner diameter approx. 58.7 mm {2.31 in}

39. Assemble the oil pump using the following procedure:

|

1

|

Oil pump

|

|

2

|

7 bolts (M8 x 1.25 bolt, length approx. 31 mm {1.2 in})

|

- (1) Assemble the oil pump.

-

- (2) Assemble and tighten the bolts shown in the figure.

-

-

Note

-

• Bolt size: M8 x 1.25 bolt (length approx. 31 mm {1.2 in})

-

Tightening torque

-

19—25 N·m {2.0—2.5 kgf·m, 15—18 ft·lbf}

40. Assemble the converter housing using the following procedure:

|

1

|

O-ring (outer diameter approx. 15.6 mm {0.614 in}, thickness approx. 2.4 mm {0.094 in})

|

|

2

|

O-ring (outer diameter approx. 73.3 mm {2.89 in}, thickness approx. 3.0 mm {0.12 in})

|

|

3

|

Converter housing

|

|

4

|

21 Bolts * (M8 x 1.25 bolt, length approx. 28 mm {1.1 in})

|

* :Of the 21 bolts, 4 are applied with sealant

- (1) Assemble new O-rings using the following procedure:

-

-

Caution

-

• If an O-ring is reused it could cause ATF leakage, therefore use a new O-ring.

- 1) Apply ATF (ATF FZ) to the new O-rings.

- 2) Assemble the new O-rings.

-

|

1

|

O-ring (outer diameter approx. 15.6 mm {0.614 in}, thickness approx. 2.4 mm {0.094 in})

|

|

2

|

O-ring (outer diameter approx. 73.3 mm {2.89 in}, thickness approx. 3.0 mm {0.12 in})

|

- (2) Remove any remaining old sealant on the contact surfaces of the transaxle case and converter housing, and degrease the contact surfaces.

-

-

Caution

-

• When degreasing and if degreaser is used, use a rag saturated with degreaser and be careful not to allow degreaser to penetrate the interior of the transaxle.

In addition, after degreasing, visually verify that there is no foreign matter (such as old sealant, cloth fibers) which has penetrated the interior of the transaxle.

- (3) Apply sealant (silicone sealant TB1217E) to the transaxle case.

-

-

Caution

-

• If sealant is applied excessively or applied to a part other than the indicated part, the O-ring could deform and the sealant could penetrate the oil passage. Apply an appropriate amount of sealant to the indicated part.

-

Note

-

• Sealant application amount (bead thickness): φ1.8—2.5 mm {0.071—0.098 in}.

- (4) Assemble the converter housing before the applied sealant starts to harden.

-

- (5) Assemble and temporarily tighten the bolts to the positions shown in the figure.

-

-

Note

-

• Bolt size: M8 x 1.25 bolt (length approx. 28 mm {1.1 in})

- (6) Assemble and temporarily tighten the new bolts to the positions shown in the figure.

-

-

Caution

-

• The bolts for the assembly are coated with sealant. If the bolts are reused it could cause ATF leakage, therefore use new bolts.

-

Note

-

• Bolt size: M8 x 1.25 bolt, length approx. 28 mm {1.1 in} (with sealant applied)

- (7) Tighten the bolts shown in the figure.

-

-

Tightening torque

-

19—25 N·m {2.0—2.5 kgf·m, 15—18 ft·lbf}

41. Remove the SSTs from the transaxle using the following procedure:

-

Caution

-

• When removing the transaxle from the SST (engine stand) using chain hoists, be careful not to allow the transaxle (oil cooler in particular) to contact the SST (engine stand). If the transaxle contacts the SST, verify the areas which are contacted and replace damaged parts with new ones.

- (1) Assemble the SSTs using part number: 9YA02 1015, or M10 x 1.5 bolt (length 35 mm {1.4 in}).

-

A :Part number: 9YA02 1015, or M10 x 1.5 bolt, length 35 mm {1.4 in}

-

Tightening torque

-

38—52 N·m {3.9—5.3 kgf·m, 29—38 ft·lbf}

- (2) Using chain hoists, remove the transaxle from the SST (engine stand).

-

-

Caution

-

• When removing the transaxle from the SST (engine stand) using chain hoists, be careful not to allow the transaxle (oil cooler in particular) to contact the SST (engine stand). If the transaxle contacts the SST, verify the areas which are contacted and replace damaged parts with new ones.

A :Part number: 9YA02 A220, or M12 x 1.75 bolt, length 40 mm {1.6 in}

- (3) Remove the SSTs.

-

A :Part number: 9YA02 1015, or M10 x 1.5 bolt, length 35 mm {1.4 in}

- (4) Disassemble the SST.

-

A :Part number: 9YA02 1440, or M14 x 1.5 bolt, length 100 mm {3.94 in}

42. Assemble the torque converter using the following procedure:

- (1) Apply ATF (ATF FZ) to the stator shaft end of the oil pump shown in the figure.

-

-

Caution

-

• Accurately perform the procedure to protect the internal parts of the torque converter.

- (2) Assemble the torque converter so that the two surfaces of the notch on the end of the torque converter engage the inner rotor of the oil pump.

-

- (3) To verify that the torque converter is securely assembled, measure the distance shown in the figure.

-

-

Note

-

• Recommended measuring instrument: Depth gauge, straight edge ruler

A :Converter housing end (alignment surface with engine)

B :Torque converter stud bolt surface

-

Specification

-

17.2 mm {0.678 in} or more

-

• If not within the specification, remove the torque converter and reassemble.

-

Note

-

- 1) Set two straight edge rulers along the alignment surface of the converter housing with the engine as shown in the figure.

- 2) Measure the positions (2 locations) shown in the figure using a depth gauge and calculate the average value.

-

A :Straight edge rulers

- 3) Subtract the thickness of the straight edge rulers from the average value.

43. Assemble and tighten the stud bolts.

-

Tightening torque

-

15—25 N·m {1.6—2.5 kgf·m, 12—18 ft·lbf}

44. Assemble the electric AT oil pump using the following procedure: (only vehicles with i-stop)

-

Caution

-

• Do not drop or apply a shock to the electric AT oil pump. Replace the electric AT oil pump with a new one if it was dropped or received an impact.

• Do not disassemble the electric AT oil pump. Replace the electric AT oil pump if it has been disassembled.

• Verify that there is no sealant or foreign matter in the electrical AT oil pump and transaxle. Otherwise, it could cause a malfunction.

• Be careful not to scratch or damage the aligning surfaces of the electric AT oil pump and end cover and the O-ring installation area so as not to cause ATF leakage.

|

1

|

O-ring (outer diameter approx. 15.6 mm {0.614 in}, thickness approx. 2.4 mm {0.094 in})

|

|

2

|

Electric AT oil pump

|

|

3

|

3 bolts (M8 x 1.25 bolt, length approx. 25 mm {0.98 in})

|

- (1) Assemble new O-rings using the following procedure:

-

-

Caution

-

• If an O-ring is reused it could cause ATF leakage, therefore use a new O-ring.

-

Note

-

• O-ring size: Outer diameter approx. 15.6 mm {0.614 in}, thickness approx. 2.4 mm {0.094 in}

- 1) Apply ATF (ATF FZ) to the new O-rings.

- 2) Assemble the new O-rings.

-

- (2) Remove any remaining old sealant on the contact surfaces of the end cover and electric AT oil pump, and clean degrease the contact surfaces.

-

-

Caution

-

• When degreasing and if degreaser is used, use a rag saturated with degreaser and be careful not to allow degreaser to penetrate the oil passage.

In addition, after degreasing, visually verify that there is no foreign matter (such as old sealant, cloth fibers) which has penetrated the oil passage.

- (3) Apply sealant (silicone sealant TB1217E) to the electric AT oil pump.

-

-

Caution

-

• If sealant is applied excessively or applied to a part other than the indicated part, the O-ring could deform and the sealant could penetrate the oil passage. Apply an appropriate amount of sealant to the indicated part.

-

Note

-

• Sealant application amount (bead thickness): φ0.5—1.5 mm {0.02—0.05 in}.

- (4) Assemble the electric AT oil pump before the applied sealant starts to harden.

-

- (5) Assemble and tighten the bolts shown in the figure.

-

-

Note

-

• Bolt size: M8 x 1.25 bolt (length approx. 25 mm {0.98 in})

-

Tightening torque

-

19—25 N·m {2.0—2.5 kgf·m, 15—18 ft·lbf}