|

bcw6ja00000163

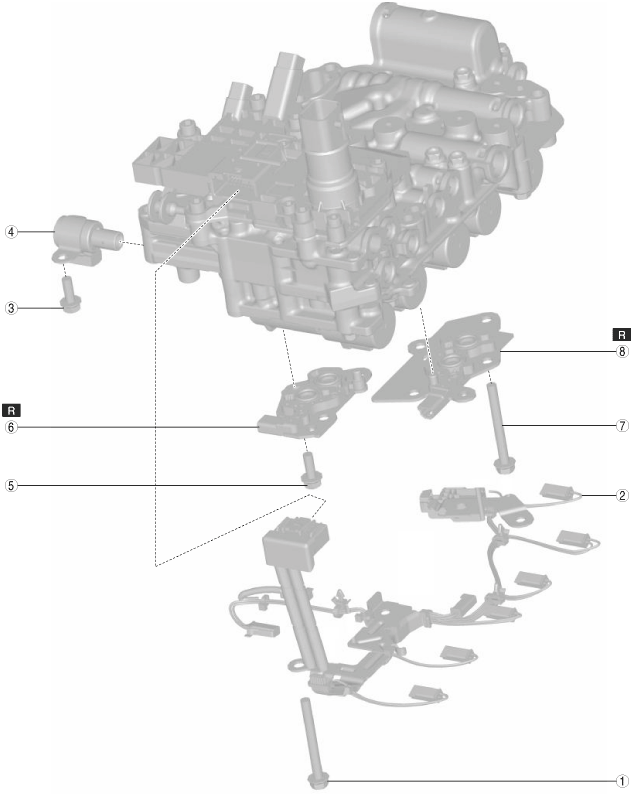

CONTROL VALVE BODY DISASSEMBLY

id051700661400

Structural view

bcw6ja00000163

|

|

1

|

4 bolts

|

|

2

|

Coupler component

|

|

3

|

Bolt

|

|

4

|

ON/OFF solenoid

|

|

5

|

3 bolts

|

|

6

|

Oil pressure switch B

|

|

7

|

4 bolts

|

|

8

|

Oil pressure switch A

|

Disassembly Procedure

bcw6ja00000597

|

bcw6ja00000027

|

1. Remove the coupler component using the following procedure.

bcw6ja00000283

|

|

1

|

4 bolts

|

|

2

|

Coupler component

|

bcw6ja00000065

|

bcw6ja00000066

|

bcw6ja00001030

|

bcw6ja00000068

|

bcw6ja00000069

|

bcw6ja00000070

|

bcw6ja00000071

|

bcw6ja00000072

|

bcw6ja00000066

|

bcw6ja00000073

|

2. Remove the ON/OFF solenoid using the following procedure:

bcw6ja00000284

|

|

1

|

Bolt

|

|

2

|

ON/OFF solenoid

|

bcw6ja00000285

|

bcw6ja00000286

|

3. Remove oil pressure switch B using the following procedure:

bcw6ja00000287

|

|

1

|

3 bolts

|

|

2

|

Oil pressure switch B

|

bcw6ja00000288

|

bcw6ja00000289

|

4. Remove oil pressure switch A using the following procedure:

bcw6ja00001031

|

bcw6ja00000290

|

|

1

|

4 bolts

|

|

2

|

Oil pressure switch A

|

bcw6ja00000291

|

bcw6ja00000292

|