|

REAR PLANETARY GEAR INSPECTION

id051700662100

Radial Needle Bearing Inspection (in Pinion Gear)

1. Place the rear planetary gear with the front internal gear side pointing upward on a workbench.

bcw6ja00000187

|

2. Rotate the pinion gears by hand and verify that there is no malfunction in the radial needle bearing in the pinion gear (rotation sticking).

bcw6ja00000188

|

Thrust Needle Bearing Inspection

1. Place the rear planetary gear with the front internal gear side pointing upward on a workbench.

bcw6ja00000187

|

2. Assemble the rear sun gear to the rear planetary gear.

bcw6ja00000189

|

bcw6ja00000190

|

3. With a load applied by hand to the rear sun gear, rotate the rear sun gear and verify that there is no malfunction in the thrust needle bearing (rotation sticking).

bcw6ja00000191

|

4. Remove the rear sun gear.

bcw6ja00000192

|

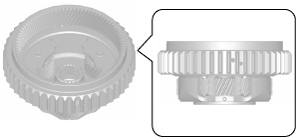

Pinion Washer Inspection

Pinion washer visual inspection

1. Visually verify that all of the following washers are between the pinion gear and planetary carrier for one pinion gear.

bcw6ja00000193

|

Pinion washer wear inspection

1. Place the rear planetary gear with the front internal gear side pointing downward on a workbench.

bcw6ja00000194

|

2. Measure the gap between the pinion washer and planetary carrier.

bcw6ja00000195

|