|

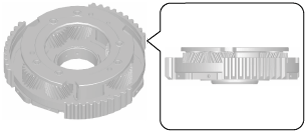

REDUCTION PLANETARY GEAR INSPECTION

id051700662200

Radial Needle Bearing Inspection (in Pinion Gear)

1. Place the reduction planetary gear on a workbench as shown in the figure.

bcw6ja00000136

|

2. Rotate the pinion gears by hand and verify that there is no malfunction in the radial needle bearing in the pinion gear (rotation sticking).

bcw6ja00000196

|

Pinion Washer Inspection

Pinion washer visual inspection

1. Visually verify that all of the following washers are between the pinion gear and planetary carrier for one pinion gear.

bcw6ja00000197

|

Pinion washer wear inspection

1. Place the reduction planetary gear on a workbench as shown in the figure.

bcw6ja00000136

|

2. Measure the gap between the pinion washer and planetary carrier.

bcw6ja00000198

|

Bush Inner Diameter Inspection

1. Measure the inner diameter of the bush shown in the figure.

bcw6ja00000199

|