|

REVERSE IDLER GEAR COMPONENT INSPECTION

id051500168400

Gear Inspection

1. Inspect the gears for damage, wear, or loss.

2. Inspect the gears and reverse lever component for damage and wear on the contact surfaces.

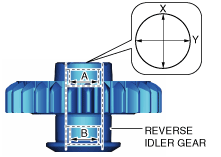

3. Measure the inner diameter of the bushing assembled to the reverse idler gear using a cylinder gauge. Measurement positions total four and are in the X and Y directions, at two points (A and B) as shown in the figure.

bf62zm00000021

|

Inner diameter of gear

|

Measurement location |

Specification (mm {in}) |

Maximum (mm {in}) |

|---|---|---|

|

Reverse idler gear bushing

|

16.025 {0.6309}

|

16.034 {0.6313}

|

Reverse Idler Shaft Inspection

1. Inspect the sliding parts for damage and wear.

2. Measure the outer diameter of the reverse idler shaft using the micrometer. Measurement positions total four and are in the X and Y directions, at two points (A and B) as shown in the figure.

bf62zm00000022

|

Reverse idler shaft outer diameter

|

Measurement location |

Specification (mm {in}) |

Minimum (mm {in}) |

|---|---|---|

|

Reverse idler shaft

|

15.975 {0.6289}

|

15.966 {0.6286}

|