|

PRIMARY SHAFT COMPONENT INSPECTION

id051500168800

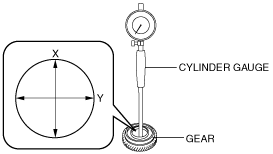

Gear inspection

1. Inspect the gears for damage, wear, or loss.

2. Inspect the gears and synchronizer rings for damage and wear on contact surfaces.

3. Measure the gear circumference in the X and Y directions as shown in the figure using a cylinder gauge.

bf62zm00000034

|

Inner diameter of gear

|

Measurement location |

Specification (mm {in}) |

Maximum (mm {in}) |

|---|---|---|

|

3rd gear

|

41.510 {1.6343}

|

41.520 {1.6346}

|

|

4th gear

|

37.010 {1.4571}

|

37.020 {1.4575}

|

|

5th gear

|

37.010 {1.4571}

|

37.020 {1.4575}

|

|

6th gear

|

32.810 {1.2917}

|

32.820 {1.2921}

|

Primary Shaft Inspection

1. Inspect the spline for damage and wear.

2. Inspect the gear area for damage, wear, and loss.

3. Measure the runout of the primary shaft.

bf62zm00000035

|

4. Measure the outer diameter of the primary shaft using the micrometer. Measurement positions total eight and are in the X and Y directions, at four points (A, B, C, and D) as shown in the figure.

bf62zm00000036

|

Outer diameter of primary shaft

|

Measurement location |

Specification (mm {in}) |

Minimum (mm {in}) |

|---|---|---|

|

A: 6th gear assembly part

|

32.770 {1.2902}

|

32.760 {1.2898}

|

|

B: 5th gear assembly part

|

36.970 {1.4555}

|

36.960 {1.4551}

|

|

C: 4th gear assembly part

|

36.970 {1.4555}

|

36.960 {1.4551}

|

|

D: 3rd gear assembly part

|

41.470 {1.6327}

|

41.460 {1.6323}

|

Synchronizer Ring Inspection

1. Inspect the teeth of the synchronizer ring for damage, wear, or loss.

2. Inspect the taper surface for wear or loss.

3. While holding the synchronizer ring and gear with your fingers as shown in the figure, measure the clearance of the synchronizer ring and gear side surface around the entire circumference using a thickness gauge.

bf62zm00000037

|

Clearance between synchronizer ring and gear

|

Measurement location |

Specification (mm {in}) |

Minimum (mm {in}) |

|---|---|---|

|

Synchronizer ring (3GR)

|

1.000 {0.0394}

|

0.435 {0.0171}

|

|

Synchronizer ring (4GR)

|

1.000 {0.0394}

|

0.435 {0.0171}

|

|

Synchronizer ring (5GR)

|

1.000 {0.0394}

|

0.520 {0.0205}

|

|

Synchronizer ring (6GR)

|

1.000 {0.0394}

|

0.520 {0.0205}

|

Clutch Hub Component Inspection

1. Inspect the clutch hub sleeve and clutch hub operation.

2. Inspect the spline for damage, wear or loss.

3. While holding the clutch hub sleeve and shift fork together with your hand as shown in the figure, measure the clearance between the shift fork and clutch hub sleeve groove using a thickness gauge.

bf62zm00000038

|

Clearance between shift fork and clutch hub sleeve groove

|

Measurement location |

Specification (mm {in}) |

Maximum (mm {in}) |

|---|---|---|

|

Shift fork (3GR/4GR)

|

0.225 {0.0089}

|

0.400 {0.0157}

|

|

Shift fork (5GR/6GR)

|

0.225 {0.0089}

|

0.400 {0.0157}

|