PURGE CONTROL [SKYACTIV-G 1.3, SKYACTIV-G 1.5]

id0140q1203800

Outline

• An appropriate amount of evaporative gas is fed into the intake manifold by the purge solenoid valve operation (according to the engine operation conditions). This ensures driveability and prevents release of evaporative gas into the atmosphere.

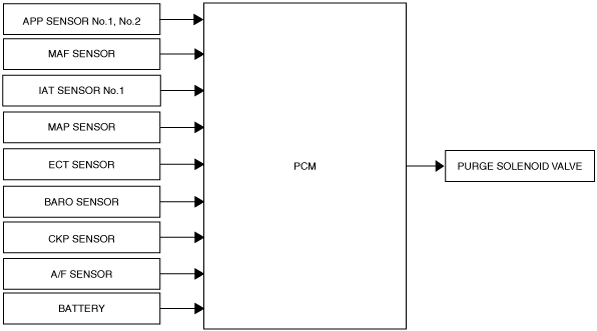

• The PCM drives the purge solenoid valve based on the signal from each control part.

Block Diagram

Operation

Calculation method for purge flow amount

-

PCM (200 pin type)

-

• The PCM calculates the purge flow amount in which the intake airflow amount and the amount of fuel vapor gas passing through the purge solenoid value are a certain ratio. The purge flow amount is corrected by the fuel vapor gas concentration and the intake air temperature.

-

PCM (186 pin type)

-

• The PCM determines the drive duty based on the calculated purge flow amount. The drive duty is corrected by the intake air temperature and the battery voltage.

Determination of purge solenoid valve energization time

-

PCM (200 pin type)

-

• The PCM determines the drive duty of the purge solenoid valve through which the purge flow amount passes. The drive duty value is corrected by the battery voltage.

-

PCM (186 pin type)

-

• The PCM calculates the optimum purge flow amount according to mainly the evaporation density, intake air volume, and injection amount of the injector.

Operation condition

-

• In evaporative purge control during normal driving, the PCM sends a duty signal to the purge solenoid valve when all of the following conditions are met.

-

― Fuel injection control is in feedback zone (λ=1)

― Engine coolant temperature 60 °C {140 °F} or more