|

PCM INSPECTION [SKYACTIV-G 1.3, SKYACTIV-G 1.5]

id0140q1802500

Engine Type

|

Item |

Reference |

|

|---|---|---|

|

PCM (200 Pin Type)

|

Without Using the M-MDS

|

|

|

With Using the M-MDS

|

||

|

PCM (186 Pin Type)

|

Without Using the M-MDS

|

|

|

With Using the M-MDS

|

||

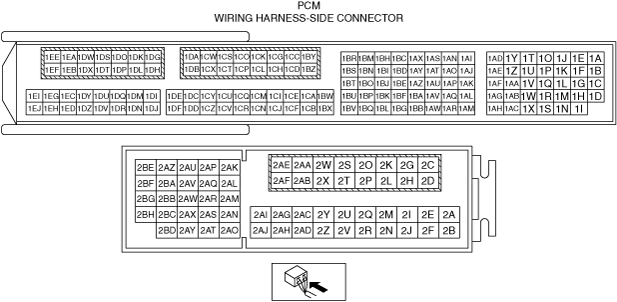

Without Using the M-MDS (PCM (200 Pin Type))

Terminal voltage table (Reference)

am3zzw00013565

|

|

Terminal |

Signal |

Connected to |

Test condition |

Voltage (V) |

Inspection item |

|

|---|---|---|---|---|---|---|

|

1A*1

|

CAN2_H

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

||

|

1B*1

|

CAN2_L

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

||

|

1C

|

—

|

—

|

—

|

—

|

—

|

|

|

1D

|

Knocking (–)

|

KS

|

Ignition switched ON (engine off) (Use digital type voltmeter, because measurement voltage will be detected less than true voltage when using analog type voltmeter)

|

Approx. 1.64

|

• KS

• Related wiring harness

|

|

|

1E

|

—

|

—

|

—

|

—

|

—

|

|

|

1F

|

—

|

—

|

—

|

—

|

—

|

|

|

1G*7

|

Neutral switch No.2

|

Neutral switch No.2

|

Switch ignition ON (engine off)

|

Neutral

|

Below 1.0

|

• Neutral switch No.2

• Related wiring harness

|

|

Except above

|

B+

|

|||||

|

1H

|

Knocking (+)

|

KS

|

Ignition switched ON (engine off) (Use digital type voltmeter, because measurement voltage will be detected less than true voltage when using analog type voltmeter)

|

Approx. 3.28

|

• KS

• Related wiring harness

|

|

|

1I

|

GND

|

Sensor shield

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1J*5

|

Electric variable valve timing motor (rotation direction)

|

Electric variable valve timing motor/driver

|

• Electric variable valve timing motor/driver

• Related wiring harness

|

|||

|

1K*2

|

Neutral position

|

Neutral switch No.1

|

Shift lever is at neutral position

|

Below 1.0

|

• Neutral switch No.1

• Related wiring harness

|

|

|

Shift lever is not at neutral position

|

B+

|

|||||

|

1L*2

|

Back-up light

|

Back-up light switch

|

Shift lever is at R position

|

Below 1.0

|

• Back-up light switch

• Related wiring harness

|

|

|

Shift lever is not at R position

|

B+

|

|||||

|

1M

|

—

|

—

|

—

|

—

|

—

|

|

|

1N

|

—

|

—

|

—

|

—

|

—

|

|

|

1O*5

|

Electric variable valve timing motor (rotation pulse)

|

Electric variable valve timing motor/driver

|

• Electric variable valve timing motor/driver

• Related wiring harness

|

|||

|

1P

|

Oil pressure

|

Oil pressure switch

|

Ignition switched ON (engine off)

|

Below 1.0

|

• Oil pressure switch

• Related wiring harness

|

|

|

Idle (after warm up)

|

B+

|

|||||

|

1Q

|

—

|

—

|

—

|

—

|

—

|

|

|

1R

|

—

|

—

|

—

|

—

|

—

|

|

|

1S

|

—

|

—

|

—

|

—

|

—

|

|

|

1T*5

|

Exhaust CMP

|

Exhaust CMP sensor

|

(See Exhaust CMP signal.)

|

• Exhaust CMP sensor

• Related wiring harness

|

||

|

1U

|

—

|

—

|

—

|

—

|

—

|

|

|

1V

|

—

|

—

|

—

|

—

|

—

|

|

|

1W

|

A/F

|

A/F sensor

|

Idle (after warm up)

|

Approx. 4.18

|

• A/F sensor

• Related wiring harness

|

|

|

1X*5

|

GND

|

Exhaust CMP sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1Y

|

Intake CMP

|

Intake CMP sensor

|

(See Intake CMP signal.)

|

• Intake CMP sensor

• Related wiring harness

|

||

|

1Z*3

|

Generator output voltage

|

Generator

|

• Generator

• Related wiring harness

|

|||

|

1AA

|

—

|

—

|

—

|

—

|

—

|

|

|

1AB

|

A/F

|

A/F sensor

|

Idle (after warm up): 0 mA

|

• A/F sensor

• Related wiring harness

|

||

|

1AC

|

GND

|

Intake CMP sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1AD

|

CKP

|

CKP sensor

|

(See CKP signal.)

|

• CKP sensor

• Related wiring harness

|

||

|

1AE*5

|

Electric variable valve timing driver (diagnostic)

|

Electric variable valve timing motor/driver

|

• Electric variable valve timing motor/driver

• Related wiring harness

|

|||

|

1AF*4

|

Generator output voltage

|

Generator

|

• Generator

• Related wiring harness

|

|||

|

1AG

|

A/F

|

A/F sensor

|

Idle (after warm up)

|

Approx. 4.01

|

• A/F sensor

• Related wiring harness

|

|

|

1AH

|

GND

|

CKP sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1AI

|

Purge control

|

Purge solenoid valve

|

(See Purge control.)

|

• Purge solenoid valve

• Related wiring harness

|

||

|

1AJ

|

IGT4

|

Ignition coil No.4

|

• Ignition coil No.4

• Related wiring harness

|

|||

|

1AK

|

ECT

|

ECT sensor

|

Ignition switched ON (engine off)

|

ECT 20 °C

{68 °F}

|

Approx. 3.10

|

• ECT sensor

• Related wiring harness

|

|

ECT 40 °C

{104 °F}

|

Approx. 2.16

|

|||||

|

ECT 60 °C

{140 °F}

|

Approx. 1.40

|

|||||

|

ECT 80 °C

{176 °F}

|

Approx. 0.87

|

|||||

|

ECT 100 °C

{212 °F}

|

Approx. 0.54

|

|||||

|

1AL

|

—

|

—

|

—

|

—

|

—

|

|

|

1AM

|

GND

|

ECT sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1AN

|

Hydraulic variable valve timing control

|

OCV

|

• OCV

• Related wiring harness

|

|||

|

1AO

|

IGT3

|

Ignition coil No.3

|

• Ignition coil No.3

• Related wiring harness

|

|||

|

1AP

|

—

|

—

|

—

|

—

|

—

|

|

|

1AQ

|

—

|

—

|

—

|

—

|

—

|

|

|

1AR

|

—

|

—

|

—

|

—

|

—

|

|

|

1AS*5

|

Engine oil control

|

Engine oil solenoid valve

|

(See Engine oil control signal.)

|

• Engine oil solenoid valve

• Related wiring harness

|

||

|

1AT

|

IGT2

|

Ignition coil No.2

|

• Ignition coil No.2

• Related wiring harness

|

|||

|

1AU

|

—

|

—

|

—

|

—

|

—

|

|

|

1AV*5

|

Ion (No.4)

|

Ion sensor No.4

|

Idle (after warm up)

|

Approx. 4.48

|

• Ion sensor No.4

• Related wiring harness

|

|

|

1AW

|

—

|

—

|

—

|

—

|

—

|

|

|

1AX

|

—

|

—

|

—

|

—

|

—

|

|

|

1AY

|

IGT1

|

Ignition coil No.1

|

• Ignition coil No.1

• Related wiring harness

|

|||

|

1AZ*5

|

Electric variable valve timing control

|

Electric variable valve timing motor/driver

|

• Electric variable valve timing motor/driver

• Related wiring harness

|

|||

|

1BA*5

|

Ion (No.3)

|

Ion sensor No.3

|

Idle (after warm up)

|

Approx. 4.48

|

• Ion sensor No.3

• Related wiring harness

|

|

|

1BB

|

GND

|

Sensor shield

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1BC

|

—

|

—

|

—

|

—

|

—

|

|

|

1BD

|

—

|

—

|

—

|

—

|

—

|

|

|

1BE*4

|

Generator field coil control

|

Generator

|

• Generator

• Related wiring harness

|

|||

|

1BF*5

|

Ion (No.2)

|

Ion sensor No.2

|

Idle (after warm up)

|

Approx. 4.48

|

• Ion sensor No.2

• Related wiring harness

|

|

|

1BG

|

GND

|

Sensor shield

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1BH

|

—

|

—

|

—

|

—

|

—

|

|

|

1BI

|

—

|

—

|

—

|

—

|

—

|

|

|

1BJ

|

Constant voltage (Vref)

|

Fuel pressure sensor

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

1BK*5

|

Ion (No.1)

|

Ion sensor No.1

|

Idle (after warm up)

|

Approx. 4.48

|

• Ion sensor No.1

• Related wiring harness

|

|

|

1BL

|

GND

|

Sensor shield

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1BM

|

—

|

—

|

—

|

—

|

—

|

|

|

1BN

|

Constant voltage (Vref)

|

CKP sensor

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

1BO

|

Constant voltage (Vref)

|

MAP sensor

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

1BP

|

TP (No.1)

|

TP sensor No.1

|

Ignition switched ON (engine off)

|

Accelerator pedal released

|

Approx. 1.15

|

• TP sensor No.1

• Related wiring harness

|

|

Accelerator pedal fully depressed

|

Approx. 4.63

|

|||||

|

1BQ

|

GND

|

TP sensor No.1, TP sensor No.2

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1BR*3

|

Generator field coil control

|

Generator

|

• Generator

• Related wiring harness

|

|||

|

1BS

|

Constant voltage (Vref)

|

TP sensor No.1, TP sensor No.2

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

1BT

|

—

|

—

|

—

|

—

|

—

|

|

|

1BU

|

TP (No.2)

|

TP sensor No.2

|

Ignition switched ON (engine off)

|

Accelerator pedal released

|

Approx. 3.95

|

• TP sensor No.2

• Related wiring harness

|

|

Accelerator pedal fully depressed

|

Approx. 0.45

|

|||||

|

1BV

|

—

|

—

|

—

|

—

|

—

|

|

|

1BW

|

MAP

|

MAP sensor

|

Ignition switched ON (engine off)

|

Approx. 4.15

|

• MAP sensor

• Related wiring harness

|

|

|

Idle (after warm up)

|

Approx. 1.96

|

|||||

|

Racing

(Engine speed: 2,000 rpm)

|

Approx. 1.33

|

|||||

|

1BX

|

GND

|

MAP sensor, IAT sensor No.2

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1BY

|

A/F sensor heater control

|

A/F sensor heater

|

• A/F sensor heater

• Related wiring harness

|

|||

|

1BZ

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CA

|

Fuel pressure

|

Fuel pressure sensor

|

Idle (ECT 80°C{176 °F})

|

Approx. 0.9

|

• Fuel pressure sensor

• Related wiring harness

|

|

|

1CB

|

GND

|

Fuel pressure sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CC

|

Drive-by-wire control (–)

|

Throttle valve actuator

|

Idle (after warm up)

Because the drive-by-wire control (-) terminal value varies depending on the vehicle, examination using only the ICC terminal is not possible. When performing the inspection, perform it together with the ICG terminal.

• Type A

• Type B

|

• Throttle valve actuator

• Related wiring harness

|

||

|

1CD

|

—

|

—

|

—

|

—

|

—

|

|

|

1CE

|

IAT (No.2)

|

IAT sensor No.2

|

Ignition switched ON (engine off)

|

IAT 20 °C

{68 °F}

|

Approx. 3.57

|

• IAT sensor No.2

• Related wiring harness

|

|

IAT 40 °C

{104 °F}

|

Approx. 2.70

|

|||||

|

IAT 60 °C

{140 °F}

|

Approx. 1.87

|

|||||

|

1CF

|

—

|

—

|

—

|

—

|

—

|

|

|

1CG

|

Drive-by-wire control (+)

|

Throttle valve actuator

|

• Throttle valve actuator

• Related wiring harness

|

|||

|

1CH

|

—

|

—

|

—

|

—

|

—

|

|

|

1CI

|

—

|

—

|

—

|

—

|

—

|

|

|

1CJ

|

—

|

—

|

—

|

—

|

—

|

|

|

1CK

|

Battery voltage

|

Main relay

|

Ignition switched ON (engine off)

|

B+

|

• Main relay

• Related wiring harness

|

|

|

1CL

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CM

|

—

|

—

|

—

|

—

|

—

|

|

|

1CN

|

—

|

—

|

—

|

—

|

—

|

|

|

1CO

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1CP

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CQ

|

—

|

—

|

—

|

—

|

—

|

|

|

1CR

|

—

|

—

|

—

|

—

|

—

|

|

|

1CS

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1CT

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CU

|

—

|

—

|

—

|

—

|

—

|

|

|

1CV

|

—

|

—

|

—

|

—

|

—

|

|

|

1CW

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1CX

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1CY

|

—

|

—

|

—

|

—

|

—

|

|

|

1CZ

|

—

|

—

|

—

|

—

|

—

|

|

|

1DA

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1DB

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1DC

|

—

|

—

|

—

|

—

|

—

|

|

|

1DD

|

—

|

—

|

—

|

—

|

—

|

|

|

1DE

|

—

|

—

|

—

|

—

|

—

|

|

|

1DF

|

—

|

—

|

—

|

—

|

—

|

|

|

1DG

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1DH

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1DI

|

—

|

—

|

—

|

—

|

—

|

|

|

1DJ

|

—

|

—

|

—

|

—

|

—

|

|

|

1DK

|

Battery voltage

|

Fuel injector relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel injector relay

• Related wiring harness

|

|

|

1DL

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

1DM

|

—

|

—

|

—

|

—

|

—

|

|

|

1DN

|

—

|

—

|

—

|

—

|

—

|

|

|

1DO

|

Fuel injection control (–)

|

Fuel injector No.1

|

• Fuel injector No.1

• Related wiring harness

|

|||

|

1DP

|

Fuel injection control (+)

|

Fuel injector No.1

|

• Fuel injector No.1

• Related wiring harness

|

|||

|

1DQ

|

—

|

—

|

—

|

—

|

—

|

|

|

1DR

|

—

|

—

|

—

|

—

|

—

|

|

|

1DS

|

Fuel injection control (–)

|

Fuel injector No.4

|

• Fuel injector No.4

• Related wiring harness

|

|||

|

1DT

|

Fuel injection control (+)

|

Fuel injector No.4

|

• Fuel injector No.4

• Related wiring harness

|

|||

|

1DU

|

—

|

—

|

—

|

—

|

—

|

|

|

1DV

|

—

|

—

|

—

|

—

|

—

|

|

|

1DW

|

Fuel injection control (–)

|

Fuel injector No.2

|

• Fuel injector No.2

• Related wiring harness

|

|||

|

1DX

|

Fuel injection control (+)

|

Fuel injector No.2

|

• Fuel injector No.2

• Related wiring harness

|

|||

|

1DY

|

—

|

—

|

—

|

—

|

—

|

|

|

1DZ

|

—

|

—

|

—

|

—

|

—

|

|

|

1EA

|

Fuel injection control (–)

|

Fuel injector No.3

|

• Fuel injector No.3

• Related wiring harness

|

|||

|

1EB

|

Fuel injection control (+)

|

Fuel injector No.3

|

• Fuel injector No.3

• Related wiring harness

|

|||

|

1EC

|

—

|

—

|

—

|

—

|

—

|

|

|

1ED

|

—

|

—

|

—

|

—

|

—

|

|

|

1EE

|

High pressure fuel pump control (+)

|

High pressure fuel pump

|

• High pressure fuel pump

• Related wiring harness

|

|||

|

1EF

|

High pressure fuel pump control (–)

|

High pressure fuel pump

|

• High pressure fuel pump

• Related wiring harness

|

|||

|

1EG

|

—

|

—

|

—

|

—

|

—

|

|

|

1EH

|

—

|

—

|

—

|

—

|

—

|

|

|

1EI

|

—

|

—

|

—

|

—

|

—

|

|

|

1EJ

|

—

|

—

|

—

|

—

|

—

|

|

|

2A

|

—

|

—

|

—

|

—

|

—

|

|

|

2B

|

—

|

—

|

—

|

—

|

—

|

|

|

2C

|

HO2S heater control

|

HO2S heater

|

(See HO2S heater control signal.)

|

• HO2S heater

• Related wiring harness

|

||

|

2D

|

—

|

—

|

—

|

—

|

—

|

|

|

2E

|

—

|

—

|

—

|

—

|

—

|

|

|

2F

|

—

|

—

|

—

|

—

|

—

|

|

|

2G

|

Brake (No.1)

|

Brake switch (No.1 signal)

|

Brake pedal released

|

Below 1.0

|

• Brake switch (No.1 signal)

• Related wiring harness

|

|

|

Brake pedal fully depressed

|

B+

|

|||||

|

2H

|

Ignition (IG1)

|

IG1 relay

|

Ignition switched ON (engine off)

|

B+

|

• IG1 relay

• Related wiring harness

|

|

|

2I

|

Ambient temperature

|

Ambient temperature sensor

|

Ignition switched ON (engine off)

|

AAT 20 °C

{68 °F}

|

Approx. 2.70

|

• Ambient temperature sensor

• Related wiring harness

|

|

AAT 30 °C

{104 °F}

|

Approx. 1.80

|

|||||

|

2J*2

|

CPP

|

CPP switch, start stop unit

|

Clutch pedal fully depressed

|

Below 1.0

|

• CPP switch

• Start stop unit

• Related wiring harness

|

|

|

Clutch pedal released

|

B+

|

|||||

|

2K

|

Main relay control

|

Main relay

|

Ignition switched ON (engine off)

|

Approx. 0.83

|

• Main relay

• Related wiring harness

|

|

|

2L

|

—

|

—

|

—

|

—

|

—

|

|

|

2M*7

|

Clutch stroke sensor

|

Clutch stroke sensor

|

Ignition switched ON (engine off)

|

Clutch pedal released

|

Approx. 4.56

|

• Clutch stroke sensor

• Related wiring harness

|

|

Clutch pedal fully depressed

|

Approx. 1.06

|

|||||

|

2N

|

—

|

—

|

—

|

—

|

—

|

|

|

2O

|

Battery voltage

|

Battery

|

Under any condition

|

B+

|

• Battery

• Related wiring harness

|

|

|

2P

|

DC-DC converter control*8

|

DC-DC converter

|

Ignition switched ON (engine off)

|

Below 1.0

|

• DC-DC converter

• Related wiring harness

|

|

|

DC-DC converter (i-ELOOP) control*3

|

DC-DC converter (i-ELOOP)

|

Ignition switched ON (engine off)

|

Below 1.0

|

• DC-DC converter (i-ELOOP)

• Related wiring harness

|

||

|

2Q*6

|

Power brake unit vacuum

|

Power brake unit vacuum sensor

|

Idle (after warm up)

|

Brake pedal released

|

Approx. 0.47

|

• Power brake unit vacuum sensor

• Related wiring harness

|

|

2R

|

Brake (No.2)

|

Brake switch (No.2 signal)

|

Brake pedal released

|

Below 1.0

|

• Brake switch (No.2 signal)

• Related wiring harness

|

|

|

Brake pedal fully depressed

|

B+

|

|||||

|

2S

|

Battery voltage

|

Main relay

|

Ignition switched ON (engine off)

|

B+

|

• Main relay

• Related wiring harness

|

|

|

2T

|

Battery voltage

|

Main relay

|

Ignition switched ON (engine off)

|

B+

|

• Main relay

• Related wiring harness

|

|

|

2U

|

IAT (No.1)

|

IAT sensor No.1

|

Ignition switched ON (engine off)

|

IAT 20 °C

{68 °F}

|

Approx. 2.64

|

• IAT sensor No.1

• Related wiring harness

|

|

IAT 40 °C

{104 °F}

|

Approx. 1.27

|

|||||

|

IAT 60 °C

{140 °F}

|

Approx. 0.66

|

|||||

|

2V

|

—

|

—

|

—

|

—

|

—

|

|

|

2W*3

|

DC-DC converter (i-ELOOP) control

|

DC-DC converter (i-ELOOP)

|

Idle (after warm up)

|

0 or B+

|

• DC-DC converter (i-ELOOP)

• Related wiring harness

|

|

|

2X

|

—

|

—

|

—

|

—

|

—

|

|

|

2Y

|

—

|

—

|

—

|

—

|

—

|

|

|

2Z

|

—

|

—

|

—

|

—

|

—

|

|

|

2AA

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AB

|

—

|

—

|

—

|

—

|

—

|

|

|

2AC

|

—

|

—

|

—

|

—

|

—

|

|

|

2AD

|

GND

|

Sensor shield

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AE*10

|

Fuel pump control

|

Fuel pump control module

|

(See Fuel pump control signal.)

|

• Fuel pump control module

• Related wiring harness

|

||

|

2AF*9

|

A/C cut-off control

|

A/C relay

|

A/C relay OFF

|

B+

|

• A/C relay

• Related wiring harness

|

|

|

A/C relay ON

|

Below 1.0

|

|||||

|

2AG

|

HO2S (–)

|

HO2S

|

Idle (after warm up)

|

Approx. 1.63

|

• HO2S

• Related wiring harness

|

|

|

2AH*6

|

GND

|

Power brake unit vacuum sensor, clutch stroke sensor*7

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AI

|

HO2S (+)

|

HO2S

|

Idle (after warm up)

|

Approx. 2.35

|

• HO2S

• Related wiring harness

|

|

|

2AJ

|

GND

|

Refrigerant pressure sensor, ambient temperature sensor

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AK

|

HS CAN_H

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

||

|

2AL

|

HS CAN_L

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

||

|

2AM*10

|

Fuel pump control (diagnostic)

|

Fuel pump control module

|

• Fuel pump control module

• Related wiring harness

|

|||

|

2AN

|

APP (No.1)

|

APP sensor No.1

|

Ignition switched ON (engine off)

|

Accelerator pedal released

|

Approx. 0.82

|

• APP sensor No.1

• Related wiring harness

|

|

Accelerator pedal fully depressed

|

Approx. 4.58

|

|||||

|

2AO

|

GND

|

APP sensor No.1

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AP

|

—

|

—

|

—

|

—

|

—

|

|

|

2AQ

|

Fuel pump control

|

Fuel pump relay

|

Ignition switched ON (engine off)

|

B+

|

• Fuel pump relay

• Related wiring harness

|

|

|

Idle (after warm up)

|

Below 1.0

|

|||||

|

2AR

|

Constant voltage (Vref)

|

APP sensor No.1

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

2AS

|

APP (No.2)

|

APP sensor No.2

|

Ignition switched ON (engine off)

|

Accelerator pedal released

|

Approx. 0.42

|

• APP sensor No.2

• Related wiring harness

|

|

Accelerator pedal fully depressed

|

Approx. 2.30

|

|||||

|

2AT

|

GND

|

APP sensor No.2

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AU

|

Cooling fan control

|

Cooling fan relay No.2

|

Cooling fan operating

|

Below 1.0

|

• Cooling fan relay No.2

• Related wiring harness

|

|

|

Cooling fan not operating

|

B+

|

|||||

|

2AV

|

Cooling fan control

|

Cooling fan relay No.1

|

Cooling fan operating

|

Below 1.0

|

• Cooling fan relay No.1

• Related wiring harness

|

|

|

Cooling fan not operating

|

B+

|

|||||

|

2AW

|

Constant voltage (Vref)

|

APP sensor No.2

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

2AX*9

|

Refrigerant pressure

|

Refrigerant pressure sensor

|

Refrigerant pressure: 1.0 MPa {10 kgf/cm2, 145 psi}

|

Approx. 1.58

|

• Refrigerant pressure sensor

• Related wiring harness

|

|

|

Refrigerant pressure: 1.1 MPa {11 kgf/cm2, 160 psi}

|

Approx. 1.72

|

|||||

|

Refrigerant pressure: 1.2 MPa {12 kgf/cm2, 174 psi}

|

Approx. 1.88

|

|||||

|

2AY

|

GND

|

MAF sensor, IAT sensor No.1

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

|

2AZ

|

Starter cut-off control

|

Starter relay, start stop unit

|

Ignition switched ON (engine off)

|

MTX

• Clutch pedal released

ATX

• Selector lever position is not P or N position

|

B+

|

• Starter relay

• Start stop unit

• Related wiring harness

|

|

MTX

• Clutch pedal fully depressed

ATX

• Selector lever position is P or N position

|

Below 1.0

|

|||||

|

2BA

|

—

|

—

|

—

|

—

|

—

|

|

|

2BB

|

Constant voltage (Vref)

|

Refrigerant pressure sensor*9, MAF sensor

|

Ignition switched ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

2BC

|

MAF

|

MAF sensor

|

Ignition switched ON (engine off)

|

Approx. 0.76

|

• MAF sensor

• Related wiring harness

|

|

|

Idle (after warm up)

|

Approx. 1.12

|

|||||

|

Racing

(Engine speed: 2,000 rpm)

|

Approx. 1.44

|

|||||

|

2BD

|

Selector lever position*1

|

TCM, start stop unit

|

Selector lever position is not P or N position

|

B+

|

• TCM

• Start stop unit

• Related wiring harness

|

|

|

Selector lever position is P or N position

|

Below 1.0

|

|||||

|

Starter interlock*2

|

Starter interlock switch, start stop unit

|

Clutch pedal fully depressed

|

Below 1.0

|

• Starter interlock switch

• Start stop unit

• Related wiring harness

|

||

|

Clutch pedal released

|

B+

|

|||||

|

2BE

|

—

|

—

|

—

|

—

|

—

|

|

|

2BF

|

—

|

—

|

—

|

—

|

—

|

|

|

2BG*6

|

Constant voltage (Vref)

|

Power brake unit vacuum sensor, clutch stroke sensor*7

|

Switch ignition ON (engine off)

|

Approx. 5.02

|

• Related wiring harness

|

|

|

2BH

|

—

|

—

|

—

|

—

|

—

|

|

Inspection Using An Oscilloscope (Reference) (PCM (200 Pin Type))

Electric variable valve timing motor (rotation direction) signal

adejjw00007909

|

Electric variable valve timing motor (rotation pulse) signal

adejjw00007910

|

Exhaust CMP signal

adejjw00007911

|

Intake CMP signal

adejjw00007911

|

CKP signal

adejjw00007912

|

Electric variable valve timing driver (diagnostic) signal

adejjw00007913

|

Generator output voltage (without i-ELOOP)

adejjw00007914

|

Generator output voltage (with i-ELOOP)

am2zzw00012352

|

Purge control

adejjw00007915

|

IGT1, IGT2, IGT3, IGT4 control

am2zzw00012353

|

Hydraulic variable valve timing control signal

adejjw00007917

|

Engine oil control signal

adejjw00007918

|

Electric variable valve timing control signal

adejjw00007919

|

Generator field coil control signal (without i-ELOOP)

adejjw00007920

|

Generator field coil control signal (with i-ELOOP)

am2zzw00012354

|

A/F sensor heater control signal

am3zzw00015902

|

Drive-by-wire control (+) signal

Type A

am3zzw00012795

|

Type B

ac3jjw00004192

|

Fuel injection control (-) signal

adejjw00007923

|

Fuel injection control (+) signal

adejjw00007924

|

High pressure fuel pump control (+) signal

am3zzw00012796

|

High pressure fuel pump control (-) signal

am3zzw00015903

|

HO2S heater control signal

adejjw00007927

|

Fuel pump control signal

am3zzw00012799

|

Fuel pump control module (diagnostic) signal

am3zzw00012800

|

Using The M-MDS (PCM (200 Pin Type))

1. Connect the M-MDS to the DLC-2.

2. Switch the ignition ON (engine off).

3. Measure the PID value.

|

Item (definition) |

Unit/Condition |

Definition |

Value type |

Condition/Specification (Reference) |

PCM terminal |

|---|---|---|---|---|---|

|

AC_PRES

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Refrigerant pressure input from refrigerant pressure sensor

|

Calculation

|

• Displays refrigerant pressure

|

2AX

|

|

V

|

Refrigerant pressure sensor voltage

|

Input

|

• Refrigerant pressure is 449 kPa {4.58 kgf/cm2, 65.1 psi}: Approx. 0.76 V

• Refrigerant pressure is 729 kPa {7.43 kgf/cm2, 106 psi}: Approx. 1.18 V

|

||

|

AC_REQ

|

Off/On

|

A/C switch status received by PCM via CAN

|

Input

|

• A/C switch off: Off

• A/C switch on: On

|

CAN

(2AK, 2AL)

|

|

ACCS

|

Off/On

|

A/C relay status input from A/C relay

|

Input

|

• A/C relay off: Off

• A/C relay on: On

|

2AF

|

|

ALTF

|

%

|

Field coil current control signal output to generator

|

Calculation

|

• Ignition switched ON (engine off): 0%

• Idle: Approx. 41—54%

• Racing (Engine speed is 2,000 rpm): Approx. 24—34%

|

1BR*5, 1BE*6

|

|

ALTF_ACT*5

|

%

|

Actually measured value of field coil current signal input from generator

|

Calculation

|

• Displays actual generator field current control duty value

|

—

|

|

ALTT V*6

|

V

|

Generator output voltage

|

Input

|

• Idle (no E/L): Approx. 14 V (This is internal calculation value and differs from terminal voltage)

|

1AF

|

|

AMB_TEMP

|

°C, °F

|

Actually measured ambient temperature input from ambient temperature sensor

|

Calculation

|

• Displays ambient air temperature

|

2I

|

|

APP

|

%

|

Accelerator pedal opening angle (relative value) with the fully released status as 0% and fully depressed status as 100%

|

Calculation

|

• Accelerator pedal released: Approx. 0%

• Accelerator pedal fully depressed: Approx. 100%

|

—

|

|

APP1

|

%

|

Accelerator pedal opening angle (absolute value) input from APP sensor No.1

|

Calculation

|

• Accelerator pedal released: Approx. 16%

• Accelerator pedal fully depressed: Approx. 91%

|

2AN

|

|

V

|

APP sensor No.1 voltage

|

Input

|

• Accelerator pedal released: Approx. 0.78 V

• Accelerator pedal fully depressed: Approx. 4.54 V

|

||

|

APP2

|

%

|

Accelerator pedal opening angle (absolute value) input from APP sensor No.2

|

Calculation

|

• Accelerator pedal released: Approx. 7.84%

• Accelerator pedal fully depressed: Approx. 45.49%

|

2AS

|

|

V

|

APP sensor No.2 voltage

|

Input

|

• Accelerator pedal released: Approx. 0.39 V

• Accelerator pedal fully depressed: Approx. 2.27 V

|

||

|

ARPMDES

|

RPM

|

Target engine speed

|

Calculation

|

• Displays target engine speed

|

—

|

|

B+

|

V

|

Battery positive voltage

|

Input

|

• Displays battery voltage

|

2O

|

|

BARO

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Actually measured barometric pressure input from barometric pressure sensor built into PCM

|

Calculation

|

• Displays BARO

|

—

|

|

BATT_CUR*7

|

A

|

Battery charge/discharge current

|

Calculation

|

• Displays battery charge/discharge current value

|

CAN

(2AK, 2AL)

|

|

BATT_DAY*7

|

—

|

Number of days elapsed since current sensor initialization

|

Calculation

|

• Displays vehicle battery days in service

|

CAN

(2AK, 2AL)

|

|

BATT_RES*7

|

—

|

Battery internal resistance (estimated)

|

Calculation

|

• Displays battery inferred internal resistance

|

CAN

(2AK, 2AL)

|

|

BATT_SOC*7

|

%

|

Battery charge condition (estimated)

|

Calculation

|

• Displays battery estimated state of charge

|

CAN

(2AK, 2AL)

|

|

BATT_TEMP*7

|

°C, °F

|

Battery temperature

|

Calculation

|

• Displays battery fluid temperature

|

CAN

(2AK, 2AL)

|

|

BATT_V*7

|

V

|

Battery voltage

|

Calculation

|

• Displays battery voltage

|

CAN

(2AK, 2AL)

|

|

BBP*3

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Power brake unit vacuum input from power brake unit vacuum sensor

|

Calculation

|

• Displays power brake unit vacuum

|

2Q

|

|

V

|

Power brake unit vacuum sensor voltage

|

Input

|

Ignition switched ON

• Power brake unit vacuum is 7.96 kPa {0.0812 kgf/cm2, 1.15 psi}: approx. 0.31 V

• Power brake unit vacuum is 97.23 kPa {0.9915 kgf/cm2, 14.10 psi}: approx. 3.93 V

|

||

|

BFP*3

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Actually measured brake fluid pressure input from brake fluid pressure sensor built into DSC HU/CM via CAN

|

Calculation

|

• Displays brake fluid pressure

|

CAN

(2AK, 2AL)

|

|

BOO

|

High/Low

|

Brake switch (No.1 signal) input status

|

Calculation

|

• Brake pedal released: Low

• Brake pedal fully depressed: High

|

2G

|

|

BPA

|

High/Low

|

Brake switch (No.2 signal) input status

|

Calculation

|

• Brake pedal released: Low

• Brake pedal fully depressed: High

|

2R

|

|

CATT11_DSD

|

°C, °F

|

Estimated catalytic converter temperature

|

Calculation

|

• Displays estimated catalytic converter temperature

Idle (after warm up)

|

—

|

|

CHRGLP

|

Off/On

|

Charging system warning light illumination status

|

Calculation

|

• Charging system warning light not illuminated: Off

• Charging system warning light illuminated: On

|

—

|

|

CLU_CUT_SW*4

|

Off/On

|

Starter interlock switch status

|

Calculation

|

• Clutch pedal released: Off (starter interlock switch OFF)

• Clutch pedal fully depressed: On (starter interlock switch ON)

|

2BD

|

|

CPP*1

|

Off/On

|

Clutch pedal position

|

Calculation

|

• Clutch pedal released: Off

• Clutch pedal fully depressed: On

|

2J

|

|

CPP*4

|

%

|

Clutch pedal position input from clutch stroke sensor

|

Calculation

|

• Clutch pedal released: approx. 0.2%

• Clutch pedal fully depressed: approx. 93.5%

|

2M

|

|

CPP/PNP*1

|

Off/On

|

Shift lever position

|

Calculation

|

• Other than neutral: Off

• Neutral: On

|

1G, 1K

|

|

ECT

|

°C, °F

|

Engine coolant temperature input from ECT sensor

|

Calculation

|

• Displays ECT

|

1AK

|

|

V

|

ECT sensor voltage

|

Input

|

Ignition switched ON (engine off)

• ECT is 29 °C {84 °F}: Approx. 2.65 V

Idle (after warm up)

• ECT is 88 °C {190 °F}: Approx. 0.71 V

|

||

|

EQ_RAT11

|

—

|

Excess air factor (estimated value) to theoretical air/fuel ratio (14.7) by fuel feedback control

|

Calculation

|

Idle (after warm up)

• ECT is 89 °C {192 °F}: Approx. 1

|

—

|

|

EQ_RAT11_DSD

|

—

|

Target excess air factor (estimated value) to theoretical air/fuel ratio (14.7) by fuel feedback control

|

Calculation

|

• Indicate target lambda (Excess air factor = supplied air amount / theoretical air/fuel ratio)

|

—

|

|

ETC_ACT

|

°

|

Actual throttle valve opening angle

|

Calculation

|

Ignition switched ON (engine off)

• Accelerator pedal released: Approx. 12.89 °

• Accelerator pedal fully depressed: Approx. 86.03 °

Idle (after warm up)

• Accelerator pedal released: Approx. 2.77—2.84 ° (ECT is 89 °C {192 °F})

|

—

|

|

ETC_DSD

|

°

|

Target throttle valve opening angle

|

Calculation

|

• Displays target TP opening angle

Ignition switched ON (engine off)

|

—

|

|

%

|

Target throttle valve opening angle (percent)

|

Calculation

|

• Displays target TP opening angle (percent)

Ignition switched ON (engine off)

|

||

|

EVAPCP

|

%

|

Purge solenoid valve control duty value

|

Calculation

|

• Idle (after warm up): 0% (Engine coolant temperature 59 °C {140 °F} or less)

• Racing (Engine speed 2,000 rpm): 33—35% (ECT is 94 °C {201 °F})

• Racing (Engine speed 4,000 rpm): 53—55% (ECT is 94 °C {201 °F})

|

1AI

|

|

FAN_DUTY

|

Displays in the M-MDS but it does not operate.

|

||||

|

FAN1

|

Off/On

|

Cooling fan relay No.2 operation status

|

Calculation

|

• Cooling fan relay No.2 off: Off

• Cooling fan relay No.2 on: On

|

2AU

|

|

FAN3

|

Off/On

|

Cooling fan relay No.1 operation status

|

Calculation

|

• Cooling fan relay No.1 off: Off

• Cooling fan relay No.1 on: On

|

2AV

|

|

FIA

|

—

|

Fuel injection amount

|

Calculation

|

• Displays fuel injection amount

Idle (after warm up)

|

—

|

|

FLI

|

%

|

Fuel level

|

Calculation

|

• Fuel gauge level F: Approx. 100%

• Fuel gauge level E: Approx. 0%

|

CAN

(2AK, 2AL)

|

|

FP

|

Off/On

|

Fuel pump relay operation status

|

Calculation

|

• Ignition switched ON (engine off): Off

• Cranking: On

• Idle (after warm up): On

|

2AQ

|

|

FP_DUTY*8

|

%

|

Fuel pump control module control duty value

|

Calculation

|

• Ignition switched ON (engine off): Approx. 55.74%

• Cranking: Approx. 95%

• Idle (after warm up): Approx. 55.74%

|

2AE

|

|

FRP_A

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Actual fuel distributor pressure

|

Calculation

|

• Ignition switched ON (engine off): Approx. 3.36 MPa {34.3 kgf/cm2, 487 psi}

• Idle (after warm up): Approx. 2.96—3.13 MPa {30.2—31.9 kgf/cm2, 430—453 psi}

• Racing (engine speed is 2,000 rpm): Approx. 3.3 MPa {34 kgf/cm2, 479 psi}

• Racing (engine speed is 4,000 rpm): Approx. 4.94 MPa {50.4 kgf/cm2, 716 psi}

|

—

|

|

FRP_A_CMD

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Target fuel distributor pressure

|

Calculation

|

• Ignition switched ON (engine off): Approx. 6 MPa {61 kgf/cm2, 870 psi}

• Idle (after warm up): Approx. 3.1 MPa {32 kgf/cm2, 450 psi}

• Racing (engine speed is 2,000 rpm): Approx. 3.37 MPa {34.4 kgf/cm2, 489 psi}

• Racing (engine speed is 4,000 rpm): Approx. 4.97 MPa {50.7 kgf/cm2, 721 psi}

|

—

|

|

FRP_A_CMD_S

|

No/Yes

|

Presence/non-presence of target fuel distributor pressure

|

Calculation

|

• With fuel distributor: Yes

• Without fuel distributor: No

|

—

|

|

FRP_A_S

|

No/Yes

|

Presence/non-presence of actual fuel distributor

|

Calculation

|

• With fuel distributor: Yes

• Without fuel distributor: No

|

—

|

|

FRT_A

|

°C, °F

|

Fuel distributor temperature

|

Calculation

|

• Displays fuel distributor temperature

|

—

|

|

FT_A_S

|

No/Yes

|

Presence/non-presence of fuel distributor temperature

|

Calculation

|

• With fuel distributor: Yes

• Without fuel distributor: No

|

—

|

|

FUEL_P_DSD

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Target fuel pressure (high pressure fuel pump)

|

Calculation

|

• Displays target fuel pressure (high pressure fuel pump)

|

—

|

|

FUEL_PRES

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Fuel pressure input from fuel pressure sensor

|

Calculation

|

• Displays fuel pressure

|

1CA

|

|

V

|

Fuel pressure sensor voltage

|

Input

|

Idle (ECT 80 °C {176 °F})

• Fuel pressure is 3 MPa {31 kgf/cm2, 435 psi}: Approx. 0.9 V

|

||

|

FUELPW

|

Sec

|

Fuel injection pulse width (fuel injector energization time) output to fuel injector

|

Calculation

|

• Idle (after warm up): Approx. 1.71 ms

• Racing (engine speed is 2,000 rpm): Approx. 1.35 ms

• Racing (engine speed is 4,000 rpm): Approx. 1.21 ms

|

No.1:1DO/1DP

No.2:1DW/1DX

No.3:1EA/1EB

No.4:1DS/1DT

|

|

FUELSYS

|

OL/CL/

OL_Drive/

OL_Fault/

CL_Fault

|

Feedback status of fuel injection control is displayed

OL: Feedback control is disabled at cold engine start

CL: During feedback control by A/F sensor and HO2S

OL_Drive: While feedback control is stopped

OL_Fault: Feedback control is disable due to system malfunction

CL_Fault: During feedback control with either A/F sensor or HO2S having a malfunction

|

Calculation

|

• Idle (after warm up): OL or CL

• Racing (engine speed is 2,000 rpm): CL

• Deceleration fuel cut (accelerator pedal released from engine speed of 4,000 rpm or more): OL-Drive

|

—

|

|

GEAR*2

|

Unknown/1st/2nd/3rd/4th/5th/6th/Not in P/Park/Neutral/Drive/Reverse

|

Gear commanded

|

Calculation

|

• Selector lever at P position: Park

• Selector lever at R position: Reverse

• Selector lever at N position: Neutral

• Selector lever is in D or M position while vehicle is stopped: 1st

|

CAN

(2AK, 2AL)

|

|

HTR11

|

Off/On

|

A/F sensor heater operation status

|

Calculation

|

• Ignition switched ON (engine off): Off

• Idle (after warm up): On

|

1BY

|

|

%

|

A/F sensor heater control duty value

|

Calculation

|

• Ignition switched ON (engine off): 0%

• Idle (after warm up): 32—34%

|

||

|

HTR12

|

Off/On

|

HO2S heater operation status

|

Calculation

|

• Ignition switched ON (engine off): Off

• Idle (after warm up): On

|

2C

|

|

%

|

HO2S heater control duty value

|

Calculation

|

• Ignition switched ON (engine off): 0%

• Idle (after warm up): 41—48%

|

||

|

IAT

|

°C, °F

|

Intake air temperature (No.1) input from IAT sensor No.1

|

Calculation

|

• Displays IAT (No.1)

|

2U

|

|

V

|

IAT sensor No.1 voltage

|

Input

|

• IAT is 20 °C {68 °F}: Approx. 2.70 V

• IAT is 40 °C {104 °F}: Approx. 1.80 V

• IAT is 60 °C {140 °F}: Approx. 1.20 V

|

||

|

IAT2

|

°C, °F

|

Intake air temperature (No.2) input from IAT sensor No.2

|

Calculation

|

• Displays IAT (No.2)

|

1CE

|

|

V

|

IAT sensor No.2 voltage

|

Input

|

• IAT2 is 20 °C {68 °F}: Approx. 3.57 V

• IAT2 is 40 °C {104 °F}: Approx. 2.70 V

• IAT2 is 60 °C {140 °F}: Approx. 1.87 V

|

||

|

IMRC

|

Displays in the M-MDS but it does not operate.

|

||||

|

IMTV

|

|||||

|

INGEAR

|

Off/On

|

Gears are engaged

|

Calculation

|

MTX

• When the following conditions are satisfied: On

• Except above: Off

ATX

• Selector lever is in R, D, or M position: On

• Except above: Off

|

CAN

(2AK, 2AL)

|

|

ISC_FBK

|

%

|

ISC feedback value

|

Calculation

|

• Displays ISC feedback value

|

—

|

|

ISC_FBK_LRN

|

%

|

Learning value for calculating ISC feedback amount

|

Calculation

|

• Displays learning value for calculating ISC feedback amount

|

—

|

|

I-Stop_OFF*3

|

Off/On

|

i-stop OFF mode

|

Calculation

|

• i-stop OFF switch OFF: Off

• i-stop OFF switch ON: On

|

CAN

(2AK, 2AL)

|

|

I-Stop_TRD*3

|

Off/On

|

i-stop transmission D position selected status

|

Calculation

|

• D position:On

• Except above: Off

|

CAN

(2AK, 2AL)

|

|

I-Stop_VSP*3

|

Off/On

|

i-stop vehicle speed history flag

|

Calculation

|

• Vehicle speed in which engine stop condition is met via i-stop control is detected: On

• Except above: Off

|

CAN

(2AK, 2AL)

|

|

I-Stop_VST*3

|

Off/On

|

i-stop vehicle stop flag

|

Calculation

|

• Vehicle stop predicted: On

• Except above: Off

|

CAN

(2AK, 2AL)

|

|

IVS

|

Off Idle/Idle

|

Idle flag

|

Calculation

|

• Racing: Off Idle

• Idle: Idle

|

—

|

|

KEYST

|

—

|

Ignition key status

|

Calculation

|

• Displays ignition key status

|

—

|

|

KNOCKR

|

°

|

Ignition timing correction for suppressing engine knock (Performs retard correction (negative indication) according to the occurrence of engine knock, and it approaches approx. 0° by the advance correction due to engine knock suppression.)

|

Calculation

|

• Ignition switched ON (engine off): 0 °

• Idle (after warm up): 0 °

|

—

|

|

LOAD

|

%

|

Ratio of actual amount of intake air to the maximum air charging amount (mass volume) of cylinder

|

Calculation

|

• Idle (after warm up): Approx. 22.35%

• Racing (engine speed is 2,000 rpm): Approx. 17.25%

• Racing (engine speed is 4,000 rpm): Approx. 19.21%

|

—

|

|

LONGFT1

|

%

|

Fuel learning correction amount estimated based on A/F sensor signal

|

Calculation

|

• Idle (after warm up): Approx. −6.25%

• Racing (engine speed is 2,000 rpm): Approx. −3.9%

• Racing (engine speed is 4,000 rpm): Approx. −3.9%

|

—

|

|

LONGFT12

|

%

|

Fuel learning correction amount estimated based on HO2S signal

|

Calculation

|

• Idle (after warm up): 0%

|

—

|

|

LOW_OIL

|

Never Detected/Detected

|

Engine oil pressure condition

• Never Detected: Engine oil pressure is high

• Detected: Engine oil pressure is low

|

Calculation

|

• Ignition switched ON (engine off): Detected

• Idle (after warm up): Detected

• Racing (engine speed is 2,000—4,000 rpm): Never Detected

|

1P

|

|

LRN_KCS

|

—

|

Knock control system learning value

|

Calculation

|

• Displays knock control system learning value

|

—

|

|

M_GEAR*1

|

Neutral/1st gear/2nd gear/3rd gear/4th gear/5th gear/6th gear/Reverse/Undefined/Auto/In_Progress/YSF/Error

|

Manual gear position

|

Calculation

|

• Displays manual gear position

|

CAN

(2AK, 2AL)

|

|

MAF

|

g/Sec

|

Mass air flow input from MAF sensor

|

Calculation

|

• Displays MAF

|

2BC

|

|

V

|

MAF sensor voltage

|

Input

|

• Ignition switched ON (engine off) (MAF: 0.59 g/s {0.078 lb/min}): Approx. 0.72 V

• Idle (after warm up) (MAF: 2.17 g/s {0.287 lb/min}): Approx. 0.97 V

• Racing (engine speed is 2,000 rpm) (MAF: 4.73 g/s {0.626 lb/min}): Approx. 1.26 V

|

||

|

MAP

|

KPa {MPa}, mBar {Bar}, psi, in H20

|

Manifold absolute pressure input from MAP sensor

|

Calculation

|

• Displays MAP

|

1BW

|

|

MAP_V

|

V

|

MAP sensor voltage

|

Input

|

• Ignition switched ON (engine off) (MAP:101 kPa {1.03 kgf/cm2, 14.6 psi}): Approx. 4.12 V

• Idle (after warm up) (MAP: 33 kPa {0.34 kgf/cm2, 4.8 psi}): Approx. 1.9 V

• Racing (engine speed is 2,000 rpm) (MAP: 26 kPa {0.27 kgf/cm2, 3.8 psi}): Approx. 1.23 V

|

|

|

MF_CAT1

|

—

|

Number of misfires in No.1 cylinder leading to catalytic converter temperature increase (catalytic converter temperature increases due to fuel combustion around catalytic converter after misfire)

|

Calculation

|

• Displays number of misfires corresponding to possible catalytic converter damage (No.1 cylinder)

|

—

|

|

MF_CAT_2

|

—

|

Number of misfires in No.2 cylinder leading to catalytic converter temperature increase (catalytic converter temperature increases due to fuel combustion around catalytic converter after misfire)

|

Calculation

|

• Displays number of misfires corresponding to possible catalytic converter damage (No.2 cylinder)

|

—

|

|

MF_CAT_3

|

—

|

Number of misfires in No.3 cylinder leading to catalytic converter temperature increase (catalytic converter temperature increases due to fuel combustion around catalytic converter after misfire)

|

Calculation

|

• Displays number of misfires corresponding to possible catalytic converter damage (No.3 cylinder)

|

—

|

|

MF_CAT_4

|

—

|

Number of misfires in No.4 cylinder leading to catalytic converter temperature increase (catalytic converter temperature increases due to fuel combustion around catalytic converter after misfire)

|

Calculation

|

• Displays number of misfires corresponding to possible catalytic converter damage (No.4 cylinder)

|

—

|

|

MF_CAT_FCC

|

—

|

Threshold of malfunction determination for number of misfires (total number in all cylinders) leading to catalytic converter temperature increase

|

Calculation

|

• Displays number of misfire determinations (for catalytic converter)

|

—

|

|

MF_CAT_TTL

|

—

|

Number of misfires (total number in all cylinders) leading to catalytic converter temperature increase

|

Calculation

|

• Displays number of misfires corresponding to possible catalytic converter damage (total)

|

—

|

|

MF_EMI1

|

—

|

Number of misfires in No.1 cylinder under conditions required by emission regulations

|

Calculation

|

• Displays number of misfires possibly affecting emission (No.1 cylinder)

|

—

|

|

MF_EMI_2

|

—

|

Number of misfires in No.2 cylinder under conditions required by emission regulations

|

Calculation

|

• Displays number of misfires possibly affecting emission (No.2 cylinder)

|

—

|

|

MF_EMI_3

|

—

|

Number of misfires in No.3 cylinder under conditions required by emission regulations

|

Calculation

|

• Displays number of misfires possibly affecting emission (No.3 cylinder)

|

—

|

|

MF_EMI_4

|

—

|

Number of misfires in No.4 cylinder under conditions required by emission regulations

|

Calculation

|

• Displays number of misfires possibly affecting emission (No.4 cylinder)

|

—

|

|

MF_EMI_FCC

|

—

|

Threshold of malfunction determination for number of misfires (total number in all cylinders) under conditions required by emission regulations

|

Calculation

|

• Displays number of misfire determinations (for emission)

|

—

|

|

MF_EMI_TTL

|

—

|

Number of misfires (total number in all cylinders) under conditions required by emission regulations

|

Calculation

|

• Displays number of misfires possibly affecting emission (total)

|

—

|

|

MIL

|

Off/On

|

Check engine light illumination status

|

Calculation

|

• Check engine light not illuminated: Off

• Check engine light illuminated: On

|

—

|

|

MIL_DIS

|

Km, ft, mi

|

Travelled distance since check engine light illuminated

|

Calculation

|

• Displays travelled distance since check engine light illuminated

|

—

|

|

NEUTRAL_SW1*4

|

Off/On

|

Neutral switch No.1 status

|

Calculation

|

• Neutral: On

• Other than neutral: Off

|

1K

|

|

NEUTRAL_SW2*4

|

Off/On

|

Neutral switch No.2 status

|

Calculation

|

• Neutral: On

• Other than neutral: Off

|

1G

|

|

O2S11

|

µA

|

A/F sensor current

|

Input

|

• Idle (after warm up): 0—50 µA

• Deceleration fuel cut (accelerator pedal released from engine speed of 4,000 rpm or more): Approx. 3.84 mA

|

1AB

|

|

O2S12

|

V

|

HO2S voltage

|

Input

|

• Idle (after warm up): 0—1.0 V

• Deceleration fuel cut (accelerator pedal released from engine speed of 4,000 rpm or more): Approx. 0 V

|

2AI/2AG

|

|

OIL_P_SOL

|

Off/On

|

Engine oil solenoid valve operation status

|

Calculation

|

• ECT below 98 °C {208 °F} and engine speed below 4,000 rpm: On

• ECT above 98 °C {208 °F} or engine speed above 4,000 rpm: Off

|

1AS

|

|

OIL_TEMP

|

°C, °F

|

Estimated engine oil temperature

|

Calculation

|

• Displays estimated engine oil temperature

|

—

|

|

PN_SW*2

|

Open/Closed

|

Parking/neutral

|

Calculation

|

• Selector lever at P position or N position: Closed

• Except above: Open

|

CAN

(2AK, 2AL)

|

|

RO2FT1

|

%

|

Fuel correction amount based on HO2S signal including SHRTFT12 and LONGFT12

|

Calculation

|

• Idle (after warm up): Approx. 0%

• Deceleration fuel cut (accelerator pedal released from engine speed of 4,000 rpm or more): Approx. 3.99%

|

—

|

|

RPM

|

RPM

|

Engine speed

|

Calculation

|

• Displays engine speed

|

1AD

|

|

SHRTFT1

|

%

|

Fuel feedback correction amount estimated based on A/F sensor signal

|

Calculation

|

• Idle (after warm up): Approx. 0%

• Racing (engine speed is 2,000 rpm): Approx. 1.56%

• Racing (engine speed is 4,000 rpm): Approx. −4.68%

|

—

|

|

SHRTFT12

|

%

|

Fuel feedback correction amount estimated based on HO2S signal

|

Calculation

|

• Idle (after warm up): 0%

|

—

|

|

SPARKADV

|

°

|

Ignition timing

|

Calculation

|

• Displays ignition timing

|

—

|

|

TP_REL

|

%

|

Throttle valve opening angle (relative value) with value at throttle valve fully close timing as the start point

|

Calculation

|

• Accelerator pedal released: Approx. 12%

• Accelerator pedal fully depressed: Approx. 82%

|

—

|

|

TP1

|

%

|

Throttle valve position No.1

|

Calculation

|

• Accelerator pedal released: Approx. 22%

• Accelerator pedal fully depressed: Approx. 92%

|

1BP

|

|

V

|

TP sensor No.1 voltage

|

Input

|

• Accelerator pedal released: Approx. 1.11 V

• Accelerator pedal fully depressed: Approx. 4.59 V

|

||

|

TP2

|

%

|

Throttle valve position No.2

|

Calculation

|

• Accelerator pedal released: Approx. 22%

• Accelerator pedal fully depressed: Approx. 92%

|

1BU

|

|

V

|

TP sensor No.2 voltage

|

Input

|

• Accelerator pedal released: Approx. 3.92 V

• Accelerator pedal fully depressed: Approx. 0.41 V

|

||

|

TPCT

|

V

|

TP sensor No.1 minimum voltage at CTP

|

Calculation

|

• Ignition switched ON (engine off): Approx. 0.5 V

|

1BP

|

|

TPCT2

|

V

|

TP sensor No.2 maximum voltage at CTP

|

Calculation

|

• Ignition switched ON (engine off): Approx. 4.5 V

|

1BU

|

|

VPWR

|

V

|

Battery positive voltage

|

Input

|

• Displays battery voltage

|

2O

|

|

VSS

|

KPH, MPH

|

Vehicle speed

|

Calculation

|

• Displays vehicle speed

|

CAN

(2AK, 2AL)

|

|

VT_EX_DES

|

°

|

4-2-1 exhaust system

• Desired intake valve timing

4-1 exhaust system

• Desired exhaust valve timing

|

Calculation

|

4-2-1 exhaust system

• Displays desired intake valve timing

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

4-1 exhaust system

• Displays desired exhaust valve timing

|

—

|

|

VT_IN_ACT

|

°

|

Actual intake valve timing

|

Calculation

|

4-2-1 exhaust system

• Displays in the M-MDS but it does not operate.

4-1 exhaust system

• Displays actual intake valve timing

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

1Y*9

|

|

VT_IN_DES

|

°

|

Desired intake valve timing

|

Calculation

|

4-2-1 exhaust system

• Displays in the M-MDS but it does not operate.

4-1 exhaust system

• Displays desired intake valve timing

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

—

|

|

VT_EX_ACT

|

°

|

4-2-1 exhaust system

• Actual intake valve timing

4-1 exhaust system

• Actual exhaust valve timing

|

Calculation

|

4-2-1 exhaust system

• Displays actual intake valve timing

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

4-1 exhaust system

• Displays actual exhaust valve timing

|

1Y*9, 1T*10

|

|

VT_EX_DUTY

|

%

|

OCV control duty value

|

Calculation

|

• Idle (after warm up): 0%

• Racing (engine speed is 2,000 rpm): Approx. 40%

|

1AN

|

Without Using the M-MDS (PCM (186 Pin Type))

Terminal voltage table (Reference)

ac5wzw00010964

|

|