SECONDARY SHAFT COMPONENTS INSPECTION

B3E051517301103

Gears Inspection

1. Inspect the synchronizer cones for wear.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

3. Inspect the synchronizer ring matching teeth for damage and wear.

-

• If there is any malfunction, replace the synchronizer ring.

Synchronizer Ring Inspection

1. Inspect the synchronizer ring teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the tapered surface for wear and cracks.

-

• If there is any malfunction, replace parts as necessary.

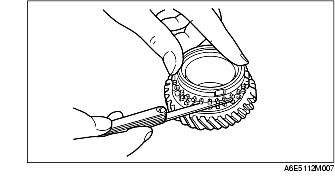

3. Measure the clearance between the synchronizer ring and the side of gear circumferentially using a feeler gauge.

-

• If it is less than the minimum specification, replace the synchronizer ring.

-

Standard clearance

-

1.30-1.70 mm {0.052-0.066 in}

-

Minimum clearance

-

1.00 mm {0.039 in}

Clutch Hub Component Inspection

1. Inspect the clutch hub sleeve and hub operation.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

3. Inspect the synchronizer keys for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

4. Measure the clearance between the hub sleeve and shift fork.

-

• If it exceeds the maximum specification, replace the hub sleeve and shift fork as a set.

-

Standard clearance

-

0.10-0.36 mm {0.004-0.014 in}

-

Maximum clearance

-

0.86 mm {0.034 in}

Secondary Shaft Gear Inspection

1. Inspect the gear contact surface for damage and wear.

-

• If there is any malfunction, replace the secondary shaft.

2. Inspect the splines for damage and wear.

-

• If there is any malfunction, replace the secondary shaft.

3. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace the secondary shaft.

4. Inspect the oil passage for clogging.

-

• If there is any malfunction, replace the secondary shaft.

5. Measure the shaft gear runout.

-

• If it exceeds the maximum specification, replace the secondary shaft.

-

Maximum runout

-

0.015 mm {0.0006 in}

6. Measure the clearance between the shaft gears and the gears.

-

• If not within the specification, replace parts as necessary.

mm {in}

|

Gear

|

Shaft

(outer dia.)

|

Gear

(inner dia.)

|

Clearance

|

|

1st

|

39.45-39.47 {1.553-1.554}

|

39.50-39.52 {1.555-1.556}

|

0.03-0.07 {0.002-0.003}

|

|

2nd

|

35.15-35.17 {1.384-1.385}

|

35.20-35.22 {1.386-1.387}

|