|

am2zzn00001072

AIM OF DEVELOPMENT

id000000100100

Product Concept

Vehicle Outline

Exterior design

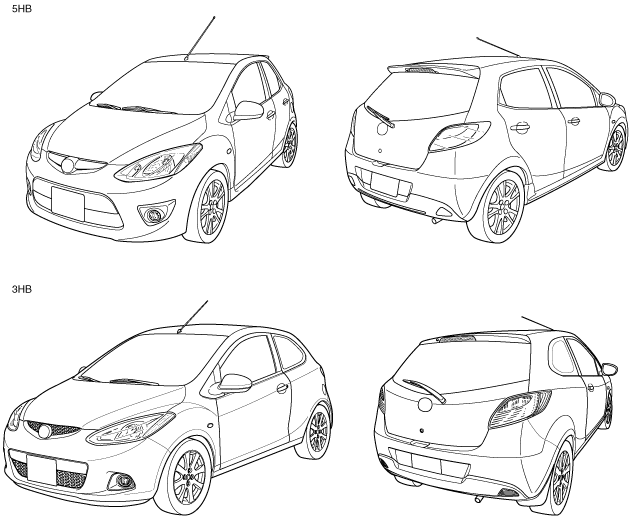

External View

am2zzn00001072

|

Interior design

am2zzn00001071

|

Engine

Suspension

am2zzn00000709

|

am2zzn00000710

|

Brakes

L.H.D.

am2zzn00001181

|

R.H.D.

am2zzn00001182

|

L.H.D.

am2zzn00001183

|

R.H.D.

am2zzn00001184

|

Antilock brake system (ABS)

L.H.D.

am2zzn00001168

|

R.H.D.

am2zzn00001169

|

Dynamic stability control (DSC)

L.H.D.

am2zzn00001173

|

R.H.D.

am2zzn00001174

|

Manual transaxle

am2zzn00000565

|

am2zzn00000963

|

Automatic transaxle

am2zzn00000175

|

Electric power steering

L.H.D.

am2zzn00001221

|

R.H.D.

am2zzn00001222

|

Safety