|

AUTOMATIC TRANSAXLE FLUID (ATF) INSPECTION

id051700800500

Automatic Transaxle Fluid (ATF) Condition Inspection

1. One way of determining whether the transaxle should be disassembled is by noting:

ATF Condition

|

Condition |

Possible cause |

||

|---|---|---|---|

|

Clear red

|

Normal

|

—

|

|

|

Light red: pink

|

Contaminated with water

|

• Broken oil cooler inside of radiator

• Poor filler tube installation:

Problem could be occurring to parts inside the transaxle by water contamination. It is necessary to overhaul transaxle and detect defective parts. If necessary, replace transaxle.

|

|

|

Reddish brown

|

Has burnt smell and metal specks are found

|

Deteriorated ATF

|

Defective powertrain components inside of transaxle: Specks cause wide range of problems by plugging up in oil pipe, control valve body and oil cooler in radiator.

• If a large amount of metal specks are found, overhaul transaxle and detect defective parts. If necessary, replace transaxle.

• Implement flushing operation as there is a possibility specks are plugging up oil pipe and/or oil cooler inside of radiator.

|

|

Has no burnt smell

|

Normal

|

• Discoloration by oxidation

|

|

Automatic Transaxle Fluid (ATF) Level Inspection

1. Park the vehicle on level ground.

2. Apply the parking brake and position wheel chocks securely to prevent the vehicle from rolling.

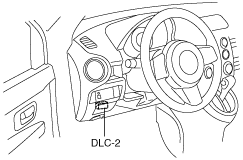

3. Connect the M-MDS to the DLC-2.

L.H.D.

am2zzw00001261

|

R.H.D.

am2zzw00000606

|

4. Monitor the ATF temperature using the M-MDS.

5. Warm up the engine until the ATF reaches 60—70 °C {140—158 °F}.

6. Shift the selector lever and pause momentarily in each range (D—L) while depressing the brake pedal.

7. Shift the selector lever to P position.

8. Verify that the ATF level is in the HOT range (65 °C {149 °F}) while the engine is idling.

am2zzw00000785

|