PISTON INSPECTION

id011000502100

-

Caution

-

• If the piston is replaced, replace the piston, piston pin, and the snap ring as a single component.

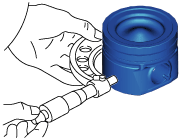

1. Measure the piston outer diameter using the micrometer. Perform the inspection at the following location.

-

• 10.0 mm {0.394 in} from the lower end of the piston (area with no coating on piston skirt)

-

― If it is not within the specification, replace the piston.

-

Standard piston outer diameter

-

75.958—75.984 mm {2.9905—2.9914 in}

2. Measure the cylinder bore diameter. (See CYLINDER BLOCK INSPECTION.)

3. Calculate the cylinder-to-piston clearance from the cylinder bore diameter and the piston outer diameter.

-

• If the clearance exceeds the maximum specification, replace the piston or cylinder block.

-

Standard clearance between piston and cylinder

-

0.031—0.049 mm {0.0013—0.0019 in}

-

Maximum clearance between piston and cylinder

-

0.067 mm {0.0026 in}

4. Measure the piston-to-ring groove clearance along the perimeter using a feeler gauge. For the O-ring, measure the clearance with the O-ring assembled to the piston.

-

• If the clearance exceeds the maximum specification, replace the piston or piston ring.

-

Standard clearance between piston ring and ring groove

-

Top: 0.10—0.14 mm {0.0040—0.0055 in}

Second: 0.05—0.09 mm {0.002—0.003 in}

Oil: 0.05—0.09 mm {0.002—0.003 in}

-

Maximum clearance between piston ring and ring groove

-

Top: 0.16 mm {0.0063 in}

Second: 0.12 mm {0.0047 in}

Oil: 0.11 mm {0.0043 in}