|

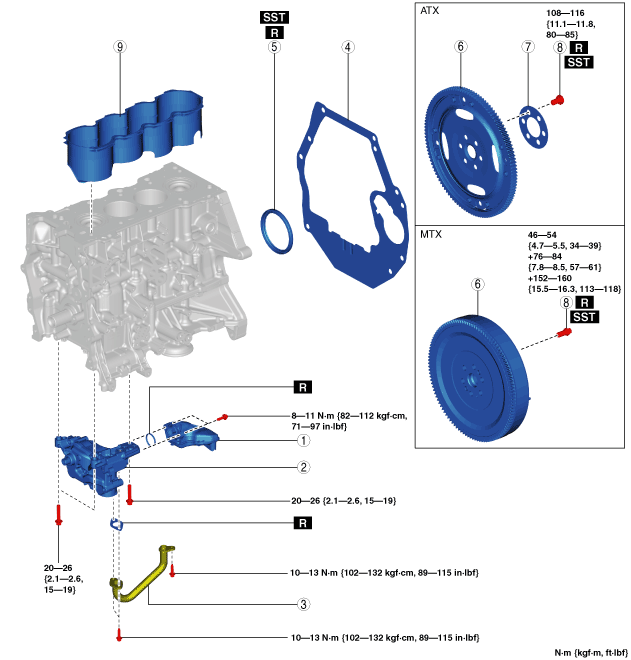

CYLINDER BLOCK ASSEMBLY (II)

id011000504100

1. Assemble in the order indicated in the table.

bes3ze00000050

|

|

1

|

Oil strainer

|

|

2

|

Oil pump

|

|

3

|

Oil pipe

|

|

4

|

End plate

(See End Plate Assembly Note.)

|

|

5

|

Rear oil seal

(See Rear Oil Seal Assembly Note.)

|

|

6

|

Dual-mass flywheel (MTX)/drive plate (ATX)

|

|

7

|

Backing plate (ATX)

|

|

8

|

Dual-mass flywheel (MTX)/drive plate (ATX) installation bolt

|

|

9

|

Water jacket spacer

|

End Plate Assembly Note

1. After end plate assembly, crimp the parts A and B shown in the figure.

bes3ze00000051

|

2. After crimping, verify that there is no damage and removal of the end plate.

Rear Oil Seal Assembly Note

1. Apply clean engine oil to the inner surface of a new rear oil seal.

2. Insert the rear oil seal into the cylinder block by hand.

3. Tap the oil seal in evenly using the SST and a hammer.

bes3ze00000052

|

bes3ze00000053

|

Dual-mass Flywheel (MTX)/Drive Plate (ATX) Installation Bolt Assembly Note

1. Clean the crankshaft thread holes.

2. Hold the crankshaft using the SST (49 E011 1A0).

MTX

adejjw00012147

|

ATX

adejjw00012417

|

3. Tighten the installation bolts.

Water Jacket Spacer Assembly Note

1. Assemble so that the rib of the water jacket spacer is facing the engine front.

bes3ze00000054

|