CYLINDER HEAD INSPECTION

id011000507100

1. Inspect the cylinder head surface for cracks and other damage using a red dye penetrant.

-

• If there is a malfunction, replace the cylinder head.

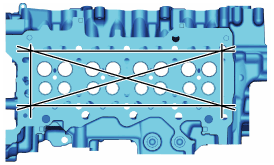

2. Measure the combustion chamber side of the cylinder head for distortion in six directions as shown in the figure using a straight edge and feeler gauge.

-

• If the distortion exceeds the maximum specification, replace the cylinder head.

-

Note

-

• Polishing and grinding for repair cannot be performed on the combustion chamber side.

-

Maximum distortion, head gasket side of the cylinder head

-

0.06 mm {0.002 in}

3. Inspect the distortion of the intake manifold and turbocharger installation surfaces using a straight edge and feeler gauge. Perform the inspection at each of the three locations as shown in the figure.

-

• If the distortion of the intake manifold and turbocharger surface is more than the maximum specification, replace the cylinder head.

-

Note

-

• Polishing and grinding for repair cannot be performed on the intake manifold and turbocharger surface.

-

Maximum distortion of intake manifold and turbocharger installation surface

-

Intake manifold installation surface: 0.05 mm {0.002 in}

Turbocharger installation surface: 0.05 mm {0.002 in}