|

am2zzn00003192

AIM OF DEVELOPMENT

id000000100100

Product Concept

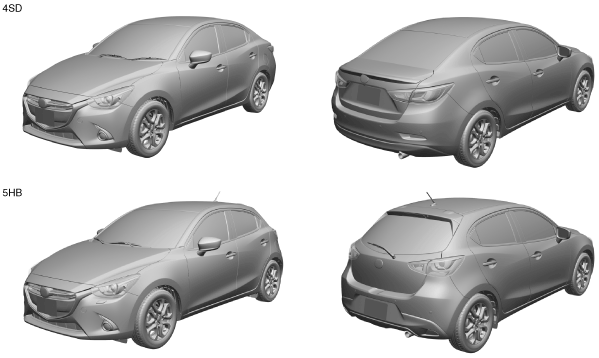

Vehicle Outline

Exterior design

am2zzn00003192

|

Interior design

am2zzn00003193

|

Engine

Suspension

am2zzn00002681

|

Rear brake (drum)

am2zzn00002682

|

Rear brake (disc)

am2zzn00002683

|

Brakes

Vehicle front side (L.H.D.)

am2zzn00001630

|

Vehicle front side (R.H.D.)

am2zzn00001631

|

Vehicle rear side

am2zzn00001632

|

Vehicle front side (L.H.D.)

am2zzn00002684

|

Vehicle front side (R.H.D.)

am2zzn00002685

|

Vehicle rear side

am2zzn00002686

|

Warning light and indicator light

am2zzn00003194

|

Vehicle front side (L.H.D.)

am2zzn00002687

|

Vehicle front side (R.H.D.)

am2zzn00002688

|

Vehicle rear side

am2zzn00002689

|

Warning light and indicator light

am2zzn00003195

|

Transaxle

am2zzn00003867

|

am2zzn00003868

|

am2zzn00002190

|

am2zzn00002360

|

Steering

L.H.D.

am2zzn00002019

|

R.H.D.

am2zzn00002020

|

Safety

Driver's support