1. Inspect the contact surface for scoring, cracks, and burning.

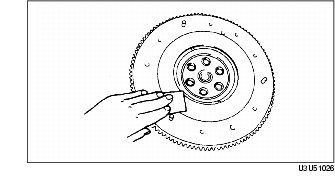

2. Remove minor scoring or burning using emery paper.

3. Inspect the ring gear teeth for wear and damage.

4. Install a dial indicator on the cylinder block.

5. Measure the flywheel runout using a dial indicator.