STEERING GEAR AND LINKAGE INSPECTION

id061400801100

Steering Rack Inspection

1. Inspect for cracking, damage, and tooth wear.

-

• If there is any malfunction, replace the steering rack.

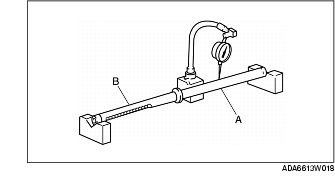

2. Measure the steering rack runout.

-

• If the runout exceeds the specification, replace the steering rack.

Steering rack runout

-

Large diameter portion (near point A): 0.15 mm {0.006 in} max.

-

Small diameter portion (near point B): 0.20 mm {0.008 in} max.

Tie-rod End Inspection

1. Inspect for damage and boot cracks.

-

• If there is any malfunction, replace the tie-rod end.

2. Inspect the ball joint for looseness.

-

• If there is any malfunction, replace the tie-rod end.

3. Rotate the ball joint five times.

4. Measure the rotational torque of the ball joint using the SST and a pull scale.

-

• If it exceeds the specification, replace the tie-rod end.

Tie-rod end rotational torque

-

0.42-2.60 N·m {4.29-26.5 kgf·cm, 3.72-23.0 in·lbf}

-

[Pull scale reading: 4.2-26.0 N {0.43-2.65 kgf, 0.95-5.84 lbf}]

Tie Rod Inspection

1. Inspect for bending and damage.

-

• If there is any malfunction, replace the tie rod.

2. Inspect the ball joint for looseness.

-

• If there is any malfunction, replace the tie rod.

3. Swing the ball joint five times.

4. Measure the swing torque using a pull scale.

-

• If it exceeds the specification, replace the tie rod.

Tie rod swing torque

-

0.1-4.6 N·m {2-46 kgf·cm, 1-40 in·lbf}

-

[Pull scale reading: 0.6-29.3 N {0.06-2.98 kgf, 0.14-6.58 lbf}]