5TH/REVERSE GEAR AND HOUSING PARTS INSPECTION

B3E051501029104

5th and Reverse Gear Inspection

1. Inspect the synchronizer cones for wear.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

3. Inspect the synchronizer ring matching teeth for damage and wear.

-

• If there is any malfunction, replace the synchronizer ring.

Synchronizer Ring Inspection

1. Inspect the synchronizer ring teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the tapered surface for wear and cracks.

-

• If there is any malfunction, replace parts as necessary.

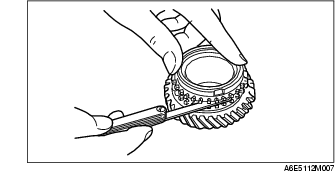

3. Measure the clearance between the synchronizer ring and the flank surface of the gear.

-

• If it is less than the minimum specification, replace the synchronizer ring.

-

Note

-

• Set the synchronizer ring squarely in the gear and measure around the circumference.

Standard clearance

-

1.12-1.88 mm {0.044-0.074 in}

Minimum clearance

-

0.80 mm {0.031 in}

Clutch Hub Component Inspection

1. Inspect the clutch hub sleeve and hub operation.

-

• If there is any malfunction, replace parts as necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

3. Inspect the synchronizer keys for damage, wear, and cracks.

-

• If there is any malfunction, replace parts as necessary.

4. Measure the clearance between the hub sleeve and shift fork.

-

• If it exceeds the maximum specification, replace the hub sleeve and shift fork as a set.

Standard clearance

-

0.40-0.75 mm {0.016-0.029 in}

Maximum clearance

-

1.25 mm {0.049 in}

Reverse Idle Gear and Reverse Lever Inspection

1. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace the reverse idle gear.

2. Measure the clearance between the reverse idle gear bushing and the reverse lever.

-

• If it exceeds the maximum specification, replace as necessary.

Standard clearance

-

0.10-0.32 mm {0.004-0.013 in}

Maximum clearance

-

0.37 mm {0.015 in}

5th Gear and Sleeve Inspection

1. Measure the clearance between the 5th gear and the sleeve.

-

• If not within the specification, replace parts as necessary.

5th gear inner diameter

-

34.01-34.03 mm {1.3390-1.3397 in}

Sleeve outer diameter

-

33.94-33.97 mm {1.3363-1.3374 in}

Standard clearance

-

0.04-0.09 mm {0.0016-0.0035 in}