|

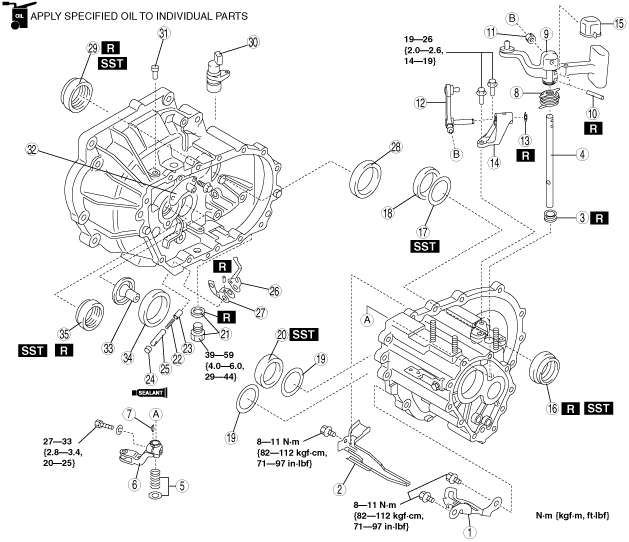

CLUTCH HOUSING AND TRANSAXLE CASE COMPONENTS ASSEMBLY [TYPE B]

B3E051517010104

1. Assemble in the order indicated in the table.

ide0515m5005

|

|

1

|

Guide plate component

|

|

2

|

Oil passage

|

|

3

|

Oil seal

|

|

4

|

Shift lever shaft

|

|

5

|

Spring and washer

|

|

6

|

Control end

(See Control End Assembly Note.)

|

|

7

|

Key

|

|

8

|

Dust boot

|

|

9

|

Shift lever

|

|

10

|

Spring pin

|

|

11

|

Change bushing

|

|

12

|

Selector lever

|

|

13

|

Bracket

|

|

14

|

Snap ring

|

|

15

|

Dust boot

|

|

16

|

Oil seal (differential)

|

|

17

|

Adjustment shim

|

|

18

|

Bearing race (differential)

|

|

19

|

Adjustment shim

|

|

20

|

Bearing race (secondary shaft)

|

|

21

|

Drain plug and washer

|

|

22

|

Blind plug

|

|

23

|

Inner shift lever

|

|

24

|

Spring

|

|

25

|

Push pin

|

|

26

|

Reverse lever

|

|

27

|

Lever set spring

|

|

28

|

Bearing race (differential)

|

|

29

|

Oil seal (differential)

|

|

30

|

Vehicle speed sensor

|

|

31

|

Breather

|

|

32

|

Breather cover component

|

|

33

|

Funnel

|

|

34

|

Bearing race (secondary shaft)

|

|

35

|

Oil seal (primary shaft)

|

Control End Assembly Note

1. Use an appropriate size pipe and fix the movement of the shift lever shaft, as shown in the figure.

adj5112m085

|

2. Using a flathead screwdriver, assemble the shift lever shaft key into the key slot.

ada5112m086

|

Oil Seal (Differential) Assembly Note

1. Apply transaxle oil to the new oil seal lip.

2. Install the oil seal using the SST.

adj5112m095

|

Bearing Preload Adjustment Note

Primary shaft assembly

1. Set the primary shaft assembly into the clutch housing.

2. Install the transaxle case to the clutch housing and tighten the bolts to the specified torque.

adj5112m061

|

3. Mount a dial indicator to the transaxle hanger and measure the primary shaft thrust clearance.

adj5112m062

|

4. Select the closest shim on the thin side from the table.

Thickness of shim

|

0.10 {0.004}

|

0.20 {0.008}

|

0.30 {0.012}

|

0.40 {0.016}

|

|

0.50 {0.020}

|

0.60 {0.024}

|

-

|

-

|

Secondary shaft bearing preload

1. Install the funnel and bearing race into the clutch housing.

adj5112m063

|

2. Set the secondary shaft into the clutch housing.

3. Install the secondary shaft bearing race into the transaxle case.

adj5112m064

|

4. Install the transaxle case to the clutch housing and tighten the bolts to the specified torque.

5. Mount a dial indicator to the transaxle case and measure the secondary shaft end play.

adj5112m065

|

6. Select the shim as follows.

(a) Add 0.03 mm {0.0012 in} to the thrust clearance.

Thickness of shim

|

0.15 {0.006}

|

0.20 {0.008}

|

0.25 {0.010}

|

0.30 {0.012}

|

|

0.35 {0.014}

|

0.40 {0.016}

|

0.45 {0.018}

|

0.50 {0.020}

|

|

0.55 {0.022}

|

0.60 {0.024}

|

0.65 {0.026}

|

0.70 {0.028}

|

Bearing Race (Differential) Assembly Note

1. Install the adjustment shim (s) and install the bearing race using the SST.

adj5112m096

|

Bearing Race (Secondary shaft gear) Assembly Note

1. Install the adjustment shim (s) and install the bearing race using a suitable pipe.

b3e515am3252

|

Oil Seal (Primary Shaft) Assembly Note

1. Apply transaxle oil to outer circumference of the oil seal.

2. Install the new oil seal using a suitable pipe.

b3e515am3256

|